100kw 500kw 1mw Biomass Electric Power Plant

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | qingdao |

| Payment Terms | Telegraphic Transfer (T/T) Letter of Credit (L/C) Western Union Letter of Credit at Sight (Sight L/C) |

| Supply Ability | 100 Per Year |

| Delivery Time | 30-60 Days |

| Main Export Market(s) | Western Europe Asia North America Eastern Europe Middle East Central America South America Australia Africa |

| Main Domestic Market | All India |

| Certifications | CEISOSGS |

Product Overview

Key Features

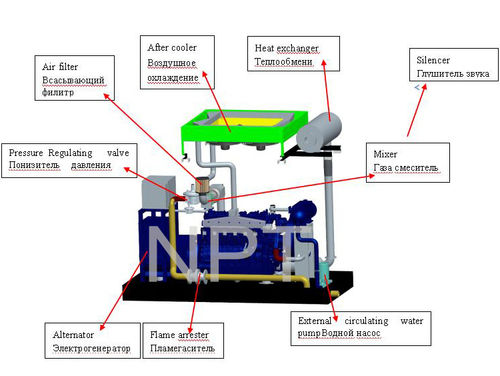

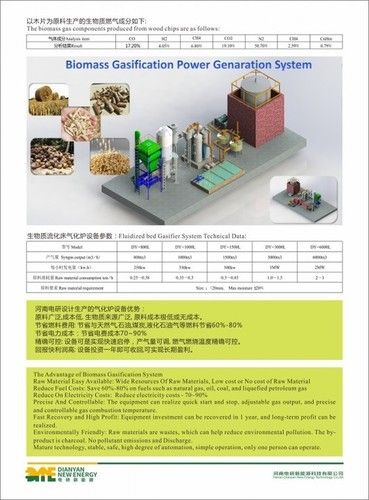

After crushing and drying the biomass material with definite size and suitable humidity is conveyed into gasifier by conveyer. The gasification agent-air- enters into gasifier by blower. The biomass material takes chemical action and converts into biomass charbiomass gas and tar at the atmosphere of high temperature and rare oxygen. Part of tar will crack into non-condensing gas under high temperature. Part of charbiomass will take reduction action with steam and carbon dioxide and generate hydrogen and carbon monoxide. After chemical action larger size charbiomass is conveyed to charbiomass production line by conveyer at the bottom of gasifier. Some small size charbiomass tar steam and gas enter into cyclone. Most charbiomass powder is separated from the mixture in the cyclone and is deliver to charbiomass production line. Then the mixture of tar steam and gas enters into tar cracking equipment. In the equipment most tar is cracked by catalyst and in converted into non-condensing gas. The gas that contains little tar enters into heat exchanger and transfers its heat to the air-the gasifier agent which can improve the heat efficiency. The cool gas with little tar enters into water scrubber. There most tar is taken away by water. The trace tar was taken away there. Now the cleaning and cooling of gas is finished. The clean gas is forced by blower and enters into gas tank to decrease the fluctuation of system. The gas follows the pipeline from gas tank to gas engine.

2. The preparation of biomass materialBefore utilization the biomass material should be treated to control the size and humidity. The humidity should be lower than 20% and the size should be not more than 80mm. The drying is need when the humidity is higher than 20%. For those irregular and higher humidity materials the crushing and drying treatment is need.

Now there are mature crushing equipments in market. The drying of material involves the supply of heat energy. If using the hot tail gas of engine as heat resource the moisture of material must be controlled strictly when the material enters into plant to avoid the imbalance of energy.

3. Biomass gasification and gas cleaning(taking an example for 1mw)

The biomass gasification adapts 1sets of fixed bed gasifier I 3.0M which can produce 3000 cubic syngas which has the advantage of fast start and stop (start the gasifier within 10 minutes and stop it within 10 minutes) broad steady load quickly following the load and easy operation (only need 2~4 workers). The material consumption depends on material. Now the preliminary cleaning method is scrubber. The gas that contains impurity enters into scrubber. The impurity is taken away by washing water. The washing water is purified by water treatment equipment. The treated water recycles in scrubber. The tar and charbiomass dust separated from washing water are sent to biomass charbiomass production line as material. Because of the evaporation of washing water some fresh water needs to be adding to scrubber.

Company Details

Focusing on a customer-centric approach HENAN YINGCHUANG MEDICAL TECHNOLOGY CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Generators in bulk from HENAN YINGCHUANG MEDICAL TECHNOLOGY CO. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2015

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Wandayu

Address

No.43 11Th Floor Building 1 No.49 Jinshui East Road Henan Free Trade Zone Zhengzhou Henan 450001 China

biomass generator in Zhengzhou

Report incorrect details