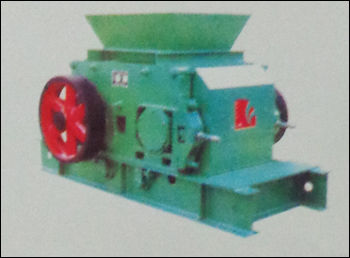

Clay Press Plate at The Lower Stage of ExtruderThis is the most key equipment in any clay brick and tile production line.Our extruder has three forms: soft plastic vacuum extruder, semi hard vacuum extruder and hard plastic vacuum extruder.Soft plastic vacuum extruder is suitable for the raw materials with moisture content higher than 19%; the allowed extrusion pressure is 2.0MPa.Semi hard vacuum extruder is suitable for the raw materials with moisture content between 16%~19%; the allowed extrusion pressure is 3.0MPa.Hard plastic vacuum extruder is suitable for the raw materials with moisture content lower than 16%; the allowed extrusion pressure is 4.0MPa.Brick Technologies (INDIA) can supply full sets of vacuum extruders, the reamer diameter is from 350mm to 750mm. According to the test data, we will equip and customize the equipment fully meeting your production demands,Extrusion end of vacuum extruder, connecting pipe, lining and 1/3 of spiral reamer all pass nickel alloyed powder spraying process to make the hardness of 1/3 spiral reamer not less than HRC50. The process is easy for the user to maintain; the users can weld or repair wear-resistant material by themselves with low cost and dispose in time.Double shaft mixing part of vacuum extruder is a mixing system to send the treated clay materials to vacuum extruder.This machine uses one motor, which is suitable for good plasticity raw materials and producing load-bearing tile, it is economical equipment considering the power supply and investment.This machine use 2 motors with the characteristics of high extruding pressure, and it is suitable for hard plasticity materials.Equipment advantages: reasonable design, compact structure, extrusion pressure and suitable for various materials, such as: coal gangue, shale, fly ash, clay and etc. Equipment parameters: Model Production Capacity (pcs/hr) Equipped Power (KW) Speed of Main Shaft (turn/min) JKY60/60-40 11000~18000 90 250 27 20 JKY55/55-40 10000~15000 75 185 27 23 JKY50/50E-40 9000~13000 55 160 38 25 JKB50/50B-38 9000~14000 55 160 38 25 JKB50/50C-35 9000~14000 55 132 38 25 JKB50/50C-32 9000~14000 55 132 35 30 JKB45/45D-35 8000~11000 45 110 35 30 JKB45/45F-30 8000~12000 45 90 42 34 JKR40/40F-25 6000~10000 37 75 40 35 JKR35/35D-20 5000~7000 30 55 42 32