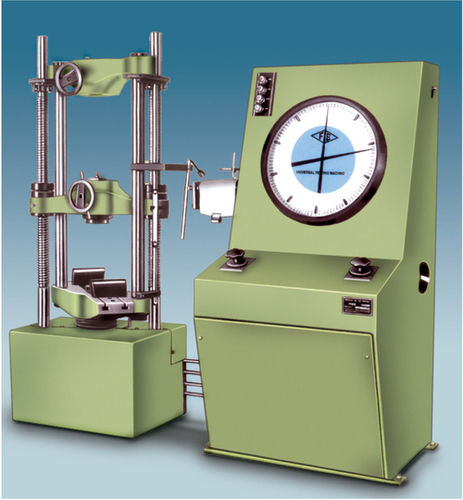

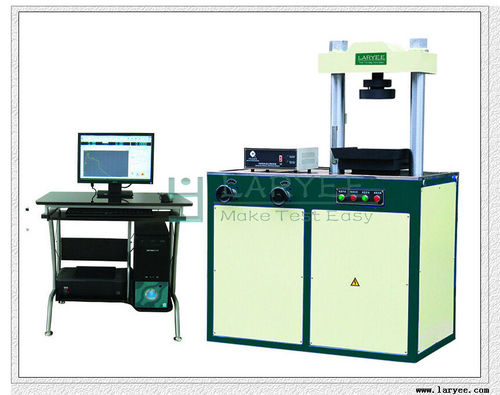

Universal Testing Machine We are an acclaimed name, engaged in offering a superior quality range of Computerised Universal Testing Machine . Our offered range is manufactured by our skilled professionals using high-grade materials and advanced technology in compliance with the international quality standards. In addition to this, our products undergo various tests to ensure their flawlessness and high efficiency. Computerised Universal Testing Machine is specially designed for testing metals and other insulating materials. Moreover, rugged construction, reliable operation, smooth performance and long operational life are some of the salient features of our entire range. Specifications: This series machines are widely used for tension, compression, bending and shearing test of metal materials and also used for compression and bending test of nonmetal materials, such as cement, concrete and so on. Equipped with simple auxiliaries, it can be used for mechanical property testing of fastener, wire rope and components. They are perfect testing instrument project quality testing section, universities and colleges, research institution and industrial and mining enterprise. The machine is designed and made according to ISO75001, ISO6892, ISO7438, ASTM A370, ASTM E4, ASTM E8 and BSEN standards. Features Control DSP card adopts PCI Socket and fast response and transfer the date from the sensor to software. Data acquisition system consists of or channels high precision A/D conversion channel. The maximum resolution of 1/300000 . There is no subsection of all process , meanwhile, it can have 4 subsections according to customers' requirement. Built-in large scale CPLD programmable device with high-speed computation capability and real-time processing digital signal. Integrated dual roads precision instrument programmable amplifier, digital zero. Load, extension, and crossehead three data input channel, it can do all kinds of material testing by any standard/ MaxTest software runs on Windows98/2000 /XP/Vista, Standard or Excel test report out put. Report format can be edition by user Real-time record and dynamic display test curve show in Load, Displacement, Extension, Stress, Strain and time. And the curve can be changed even in testing procession Adopts human-computer interaction to analyze and count performance indicators of materials. Software can automatically analyze testing data, such as tensile strength, yield strength, modulus of elasticity, extend rate after rupture, non-proportional extend strength RP0.2, etc. Adopts standard database to manage test data and support batch test. Customer can define add test methods and rules for his need. Technical Specifications Parameters WEW-300B WEW-600B WEW-1000B WEW-2000B Measuring range of force(kN) 6-300kN 12-600kN 20-1000kN 40-2000KN Accuracy +1% of indicated value Subsection of force 1,2,5,10 Accuracy of deformation measurement +0.5%F.S Clamping diameter for round specimen(mm) 10-32 13-40 13-60 20-70 Clamping width of flat specimen(mm) 70 75 80 110 Clamping thickness of flat specimen(mm) 0-15 0-30 0-40 0-50 Testing space Tension 650 650 700 700 Compression 550 550 600 600 Compression Platen size 170x170 170x170 205x205 300 Distance of bending by pass roll(mm) 30-320 30-450 30-450 30-800 Piston stroke(mm) 250 Power supply 380/220v+10%, 50/60Hz, 3 phase Working environment Room temperature 10oC~30oC relative humidity<80% Overall dimension(mm) Host machine 800x500x1950 950x630x2265 980x650x2450 1250x850x2800 Control cabinet 1070x810x1730 1070x810x1730 1070x810x1730 1070x810x1730 Weight(Kg) 2100 2700 3500 7000