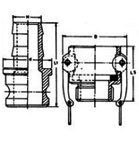

For highly stressed shaft-hub connectionThe shrink fit is unsurpassable. No other shaft hub connection can offer anywhere near the same. Performance regarding fatigue strength under the alternating tortional stresses. These fit are nevertheless rare, as they call for involved calculations extremely close matching tolerance cause considerable trouble when fitting and removing the parts in questin and give rise to problems during repair work. (exchangeability, adjustments centering etc.)CharacteristicsTransmission of high peripheral forces: Several Locking assemblies (SfN 7012) can be used in series. The transmission torque and axial loads are added.Freedom from wear: Having no moving parts, Locking assemblies (SfN 7012), can be tightened and released as often as required. The Locking screw are standard screw are standard items and thus readily available.Unlimited application range: Locking Assemblies are most suitable for securing all types of bosses and hubs on shafts and axles. They efficiently replace shrinkfits, key and polygon connections, chain sprockets, levers, cams, camplates, belt pulley, rollers, brake drums, flywheels, couplings and clutches, shaft mounted gearing, flanges, ropesheaves, trackwheels, impellers etc. and many more unlimited application. What you imagine without keys.AdvantagesSimplified manufacturing: Locking assemblies can bridge relatively large clearance without any significant torque losses. All charances between K11 and H11 and N11 and H11 are respectively possible.We recommend tolerance for shaft H9 and for hub H9.Economical: No keyways, no keys, splines, plygaon are required, so simplified manufacturing of shafts and hub.Infinitly adjustable: Locking assemblies (SfN 7012) needs no stops, Bosses and hub can therefore be located and locked at any point of shaft radially and axacially.Perfect true running: Forming a frictional lock connection, Locking assemblies have absolutely no play.High fatigue strength under alterating torsional stress: Neither shaft nor hub have keyways. Thus notch effect is minimized. Hub and shafts not weakened by keyways.Easy mounting and removal: Mounting is easy by Locking assemblies are tightened using standard screws and standard tools. No machining or fitting work required. By releasing the locking screws, Locking assemblies can be easily removed.Installation and removal instructionsMounting:Lightly oil Locking Assemblies, Do not use oil with molybedum disulphide or high pressure additions and not grease.Slide on hub and insert Locking assemblies.Tighten diagonally opposite screws, align hub with a torque wrench to tightening torque Ma.Tighten all screws in turn with torque wrench to torque Ma. If possible this procedure should be repeated after the first applications of stress onto the Locking assemblies.Dismounting:Normally the Locking assemblies releases itself, When the clamping screws opposite are released in stages.Loosen opposite clamping screws in stages.Lightly tap the clamping screws.If thrust ring at the front is locked, use screws of next size up unscrewed into threads where the plated screws are located and pull ring off.