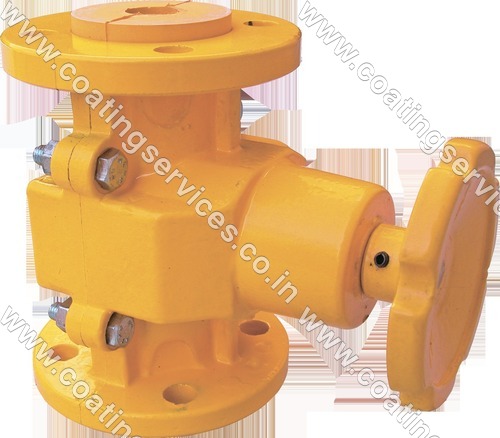

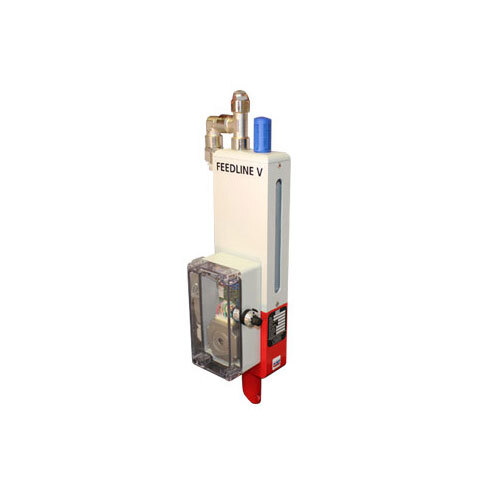

Semi Automatic Feedline V - Abrasive Metering System

Price:

Get Latest Price

Minimum Order Quantity :

50 Unit

In Stock

Product Specifications

| Technology | CNC |

| Power Source | Electricity |

| Operating Type | Semi Automatic |

| Surface Treatment | Painted |

| Supply Ability | 1000 Per Month |

| Delivery Time | 10 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Stable and repeatable operating parameters are a fundamental requirement for high-quality waterjet

cutting. This applies in particular to abrasive applications used to cut brittle materials where a

constant fl ow of abrasive is simply a must. KMT WATERJET SYSTEMS responded to this demand by

developing the FEEDLINE abrasive metering system. Controlled through a central CNC controller or a

potentiometer the FEEDLINE supplies the cutting head with the optimized fl ow of abrasive. This helps

save material and costs.

cutting. This applies in particular to abrasive applications used to cut brittle materials where a

constant fl ow of abrasive is simply a must. KMT WATERJET SYSTEMS responded to this demand by

developing the FEEDLINE abrasive metering system. Controlled through a central CNC controller or a

potentiometer the FEEDLINE supplies the cutting head with the optimized fl ow of abrasive. This helps

save material and costs.

Company Details

About Karolin Machine Tool Private LimitedWaterjet technology was introduced first in 1968 by Dr. Norman Franz professor at the University of British Columbia in Canada who developed the patented concept of high pressure waterjet cutting system Water Jet Cutting System Cnc Waterjet Cutting Machine Waterjet Cutting System a first in itself that uses water pressure of 700 bar for treating metal items. In 1971 the waterjet cutting system get its advanced version with a pressure of 4000 bar that was fabricated by the paper tube division of Alton Box Board Co. However due to its limited efficiency the system was not apt for cutting metal. During 1980 after further advancements highly sophisticated water jet technology came in the market that is used to cut a wide range of products like plastic glass metal ceramic composites and man

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

4

Establishment

1999

Working Days

Monday To Sunday

GST NO

27AACCK6308G1ZN

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AACCK6308G1ZN

Mumbai, Maharashtra

Country Manager

Mr Bhavin B Mavani

Members since

3 Years

Address

2 & 3 Srishti Plaza. Indian Cork Mill Compound Off Saki Vihar Road Powai Mumbai Maharashtra 400072 India

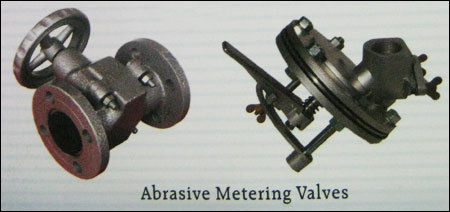

abrasive metering valves in Mumbai

Report incorrect details