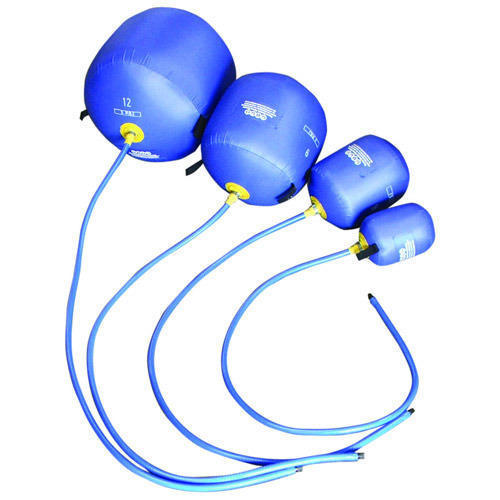

Any Inflatable Bag Weld Purge System

Price: 10000 INR / Pair

Get Latest Price

Minimum Order Quantity :

8 Pair

In Stock

Product Specifications

| Tensile Strength | 500 Pounds per Square Inch (psi) |

| Color | ANY |

| FOB Port | CHENNAI, INDIA |

| Payment Terms | Cash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA) |

| Supply Ability | ANY Per Month |

| Delivery Time | 7 TO 30 Days |

| Packaging Details | FREIGHT WORTHY |

| Main Export Market(s) | Middle East, Africa, Asia |

| Main Domestic Market | All India |

| Certifications | ISO 9001 CERFTIFIED COMPANYPRODUCT MANUFACTURED IN ACCORDANCE WITH RELVAND STANDARDS AND PREVAILING SPECIFICATIONS |

Product Overview

Key Features

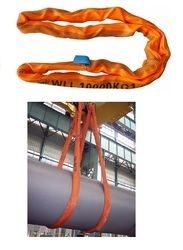

Backing Gas and Purging solutions for high quality oxide free welds.

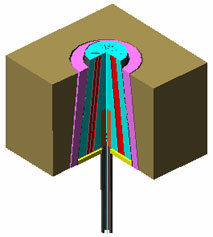

Our Inflatable Pipe Purging Systems are designed to maximise time and minimise cost. Two inflatable bladders are joined by a braided gas hose. Using inert gas(such as argon) to first inflate both bladders on either side of the weld before releasing the gas(via a pre set valve) into the chamber they have created, forcing the oxygen out through exhaust tubes built into the bladders. The Oxygen is removed so the welder can weld the pipes without the risk of oxidisation. Once the gas flow is stopped the bags deflate and are easily removed from the pipe. Used in conjunction with our Oxygen Monitors, these systems enable the welder to produce highest quality welds in very little time and with no Oxidisation.

Range 2" to 48"

INFLATABLE PIPE STOPPERS

Inflatable Pipe Stoppers are supplied as standard with no through tube. Through tubes can be supplied when the stoppers are required for weld purging applications.

When deflated, the inflatable stoppers can be inserted and withdrawn with ease.

Each inflatable stopper comes with an inflation hose fitted with a schrader valve enabling inflation with a standard airline, bicycle or foot pump.

We offer a range of shapes and sizes of inflatable stoppers, suitable for all applications. Made from a natural rubber bladder covered in waterproof polyurethane coated nylon to prevent friction and static electricity build up.

There are six different types available

a c Cylindrical

These are generally used for blocking pipes where access is restricted.

a c Spherical

These stoppers have less contact area than cylindrical stoppers, and are most suited to applications where access is further limited. Due to its shape the spherical inflatable stopper can be used at any angle.

a c Square / Rectangular

These stoppers have a variety of applications, including in air conditioning ducting and venting.

a c Doughnut

These stoppers require minimal space and are perfectly suited to larger diameter pipes as there is less inflation required.

a c Sausage

The design of this type gives more contact area between the stopper and the pipe wall enabling these stoppers to hold back more pressure.

a c Heat Resistant

These stoppers are made from a specially designed kevlar and mix material to withstand temperatures up to 932A f/500A c for applications involving higher temperatures such as pre heating.

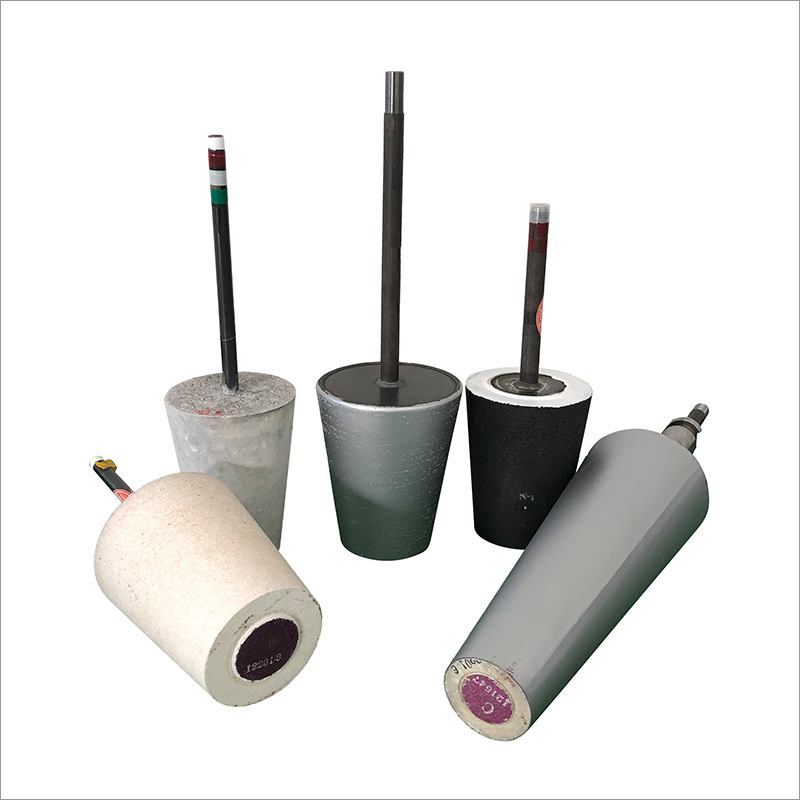

EXPANDING PIPE STOPPERS

A central spindle/shaft on which two plates are fitted with a natural rubber tyre (ring) between them, a wing nut on the shaft moving the two plates together compressing the tyre and making the seal in the pipe. Natural rubber tyres which can be substituted for different rubbers where additional chemical and/ or heat resistance is required. Alternative rubber ring options are: Silicone, Nitrile & Viton) These can also be supplied with a hollow shaft version for screwing on standard hose connections or for using fixed or free nipple caps. Expandable Pipe Stoppers are available manufactured from Nylon, Aluminium and Steel.

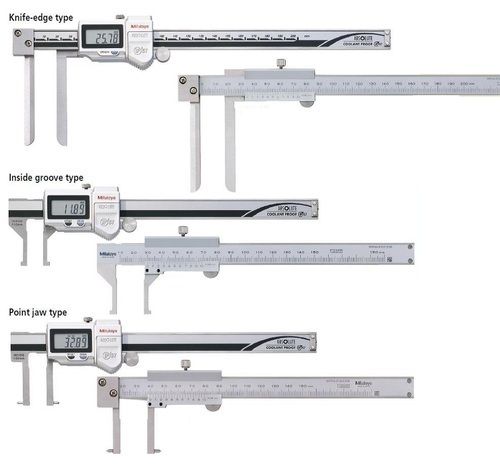

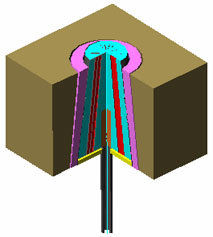

TUBE EXPANDERS

Tube Expanding is the art of reducing a tube wall by compressing the outer diameter of the tube against a fixed container such as rolling tubes into tube sheets, drums, ferrules or flanges.

Construction of heat exchangers, boilers, and surface condenser tubes is mainly limited to copper, steel, stainless steel, and cast iron with exceptions such as the use of titanium in ultra high pressure vessel applications.

To assure a proper tube joint, the tube wall must be reduced by a predetermined percentage dependent upon the material the tube is constructed of. Pneumatic or hydraulic torque rolling devices with an expander are used to expand the end of the tube so it seals against the tube sheet of the vessel.

Related Products

More Product From This seller

Company Details

S.H.Industrial Needs is a leading broadline supplier of maintenance,repair and operating (MRO) products serving Industries and Institutions PAN India, exports to middle east & Africa. Esatblished in 1987, we have been providing a wide and highly specialized range of Industrial Consumables to the Oil & Gas, Energy, Heavy Engineering, Automobile and Construction Industry. We import, export, stock and distribute more than 1 million products from 3000+ global brands to keep the facility up and running smoothly. We can help you with some hard to find engineering products, some new innovative solutions to your Safety & Tooling requirements, Material Handling, Hydraulics & Pneumatics, Fasteners, Welding, etc. All our products meet international norms and specifications, hence helping our customers stay compliant and safe.

Business Type

Importer, Supplier, Trading Company

Employee Count

10

Establishment

1987

Working Days

Monday To Sunday

GST NO

33ABCPS3480R1Z3

Certification

ISO 9001: 2015

Explore Related Categories

Seller Details

GST - 33ABCPS3480R1Z3

Chennai, Tamil Nadu

Proprietor

Mr M. S Shabbir

Members since

6 Years

Address

42/1, Armenian Street, George Town, Chennai, Tamil Nadu, 600001, India

purging plug in Chennai

Report incorrect details