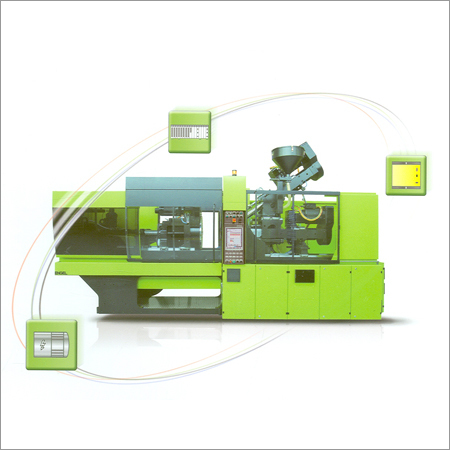

Maxima

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Red |

| Clamp Speed | 900 Mm/Sec |

| Models | Mt-500, 660, 800 |

| Injection Type | Twin Cylinder |

| Screw Ratio | 20:1 L/D |

| Control System | Closed Loop |

| Valve Type | Smart Valve |

| Features | Increased Speed, Reduced Tonnage, Greater Flexibility, Reduced Setup, Lower Operating Cost, Reduced Footprint, Improved Parallelism, Mould Protection, Even Force, Long Guided Length, Improved Alignment, Precise Control, Excellent Quality, Energy Efficient, Repeatable Cycle, Fail Safe Position |

Product Overview

Key Features

Available in : MT - 500, 660, 800.

CLAMP UNIT

Over conventional 3-platen machine

Increased performance - 50% increase in clamp speed and 80% reduction in tonnage build time.Greater flexibility - Longer stroke & daylight with large tie bar spacingReduced setup time - No ram spacers to change - Easy access to ejector mechanismLower operating cost- Reduced power consumption - 48% less hydraulic oilReduced footprint by an average of 15%Clamp speeds upto 900 mm/sec. minimize the mould open and close timeFully supported strain rods that guide the moving platen. This eliminates bushing wear. Maintains platen parallelismClosed loop mould protect for sensitive control of mould safety.Rigidity in clamping due to shorter active span of tie bar and direct acting ram building tonnage in the center of the platen.Shorter tonnage build stroke increases seal lifeSubstantial reduction in horse power due to smaller volume of oil required to build tonnage.Long guided length of the moving platen ensures parallelism and stability even with heavy moldsDesigned so the force is evenly distributed

across the tie bar grooves and proximity switches verify correct

closure position prior to lockExclusive designed hose carrier ensures that all hoses are kept from bending or crimping in a safe, smooth moving assembly

INJECTION UNIT

Friction less linear bearing guide ways improves the injection power and cylinder alignmentsInjection units include both twin injection cylinders and twin pull-in cylinders for precise alignmentConfigurable injection velocity transfer points by percentage, volume and position for easier injection setupsAll standard screws have a 20:1 L/D ratio or higher gives good homogeneity and consistent melt quality100% true closed loop injection processPID temperature controller with automatic PID tuning ensures temperature accuracy with all the material

TRUE CLOSED LOOP SYSTEM

It does continuous correction to match actual

velocity and pressure with set value, independent of external

influences, such as oil temperature & viscosity changes, melt

viscosity changes, etc.

Precise injection profile control results into excellent product qualityPrecise mould filling for intricate profiles of varying cross sectionShot weight consistencyBetter finish of articleDelivers higher injection power for the same connected loadThin wall articles can be filled easilyEnergy efficient machine

SMART VALVE

Low hysteresis - More repeatable cycle to cycleNo mechanical feedback failures - Feedback is electric eliminating mechanical feedback failureFail safe position - Eliminates hydraulic interrupt in valve stack

DESIGN FEATURES

5 Stage closed loop

injection velocity profile

11 Stage closed loop

injection pressure profile

Extruder features 5 stage

screw rpm for precise melt quality as well as closed loop back

pressure control

Proportional control of all

machine functions: clamp, injection, eject and extruder

Standard injection features

include: semi-auto purge, sprue break, manual mould purge, flow mould and

insert moulding

Auto heat start up and auto

heat shut down maximizes production up-time

Extruder over run with

process alarm

Decompression before and

after extruder run

3 Clamp closing speeds and 4

clamp opening speeds

Ejector on fly for faster

cycle time

Eject retract limit switch

verification for mould safety

Pulsating eject upto 9

pulses

Third plate pick up provides

additional clamp speeds

Adjustable pack velocity

provides additional control of injection

10.4" colour LCD with 1 to 4

active split screens on the control

SPC - Statistical Process

Control

Full flow oil filtration for

greater protection of machine components and longer life

Low oil level monitor with

alarm protects machine components

Company Details

Focusing on a customer-centric approach, Plastics Processing Machine Manufacturer Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from Plastics Processing Machine Manufacturer Pvt Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

200

Establishment

1996

Working Days

Monday To Sunday

Certification

ISO 9001

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Vice President- International Sales

Mr. Jagdish Bhandari

Address

Plot no. 93/2 & 94/1, Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382445, India

Injection Moulding Machine in Ahmedabad

Report incorrect details