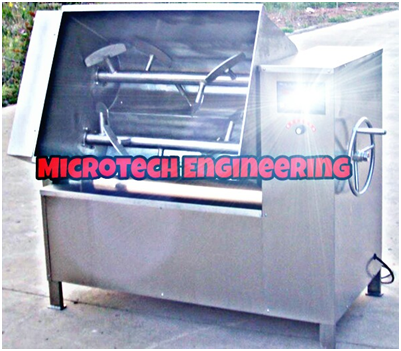

Mixing Blending Tank Diameter: Standard Millimeter (Mm)

Price: 35245.00 INR / Number

(35245.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Length | standard Millimeter (mm) |

| Weight | standard Kilograms (kg) |

| Width | standard Millimeter (mm) |

| Product Type | Mixing Blending Tank (vessel) |

| Height | standard Millimeter (mm) |

| Size | standard |

| Color | mirror polish |

| Usage | Cosmetic, Shampoo, Soap, Toothpaste,Hotels, Manufacturing Plant, Food & Beverage Factory, Farms |

| Condition | New |

| Diameter | standard Millimeter (mm) |

| Construction | Wire Mesh |

| Filtration Grade | Others |

| Medium Filter | Other |

| Shape | standard |

| Warranty | yes |

| Feature | Mixing Blending Tank (vessel) |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Western Union, Cash on Delivery (COD), Others, Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 100 Per Year |

| Delivery Time | 100 Years |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | WOODEN CHARGE |

| Main Export Market(s) | Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia |

| Main Domestic Market | All India |

| Certifications | ISO 9001-2008MSME |

| Price Type | fixed |

| Returnable | No |

| Price | 35245.00 INR (Approx.) |

| Moq | 1 |

| Packsize | 1 |

| Brand Name | MICROTECH ENGINEERIN |

| Currency | INR |

| Stock Quantity | 15 |

| Color | mirror polish |

| Product Unit | 1 Number |

| Unit Type | Number |

| Mop | 1 |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

We always supply a documentation package containing manufacturing methods, material certificates and outside inspection, where applicable.

We manufacture vessels used in industries such as brewing, pharmaceutical, chemical and food, so our stock range will suit most customer requirements. Different types of storage vessels:-

Bulk storage vessels (stainless steel / mild steel)

Mixing vessels

Fermentation vessels

Powder silos

Bright beer tanks

Process vessels

Cellar tanks

Micro breweries

Brew houses

Horizontal vessels

SS Storage tanks with optional agitators

SS Insulated storage tanks with optional agitators

SS Jacketed insulated storage tanks with agitators

Tiltable hemispherical heating vessels with agitators

Cooling Tanks

Jacketed Reactors

Tilting Pan

Agitated Vessels

Chemical Storage Tanks

Ghee Settling Tank

Horizontal Mixers

Milk Cooling Plant

PUF Insulated Liquid Storage Tank

Steam Jacketed Kettles

Steel Vessels

Sugar Melting Vessel

Sugar Syrup Making Machine

Syrup Making Machine

Tilting Paste Kettle

Vacuum Insulated Storage Tanks

Stainless Steel Vessels

Mixing Kettles

Stainless Steel Dimple Jacket Storage Tank

Dimple Jacketed Tank

Blending and Mixing Tanks

Stainless Steel Insulated Storage Tanks

SS Industrial Pressure Cooker

Milk Storage Tanks

Storage Vessels

Insulated Tank

Liquid Mixers

Milk Cooling Tanks

Syrup Mixer

Vacuum Pan and Boilers

Storage vessels/tanks are simple vessels used for storing liquids, solutions or pharmaceutical raw material and other chemicals. These general purpose vessels are made of stainless steel, fibre glass, titanium, galvanized steel etc. and are used by a number of industries to store various substances and solutions. Storage tanks/vessels can either be horizontal or vertical in their orientation.

Horizontal storage vessel is generally mounted on stands or saddles and have an access port either at the bottom or at the top. Vertical storage tanks are erected vertically and have access ports at bottom. These specialized tanks can either be placed above or underground, depending on the construction of the storage facility. The thickness of wall of these tanks/vessels also determine their application or use; while single wall storage tanks can be used for general application, double walled tanks/vessel are used for high pressure considerations.

Related Products

More Product From This seller

Company Details

We are among the Reputed Manufacturer and Exporter of Globe Valve, Hydraulic Globe Valve, Back Pull Out Pump, Dosing Pump, Filter Press Pump, Forged Instrument Pipe Fittings, Magnetic Drive Pump, and many more. These products are manufactured with advanced technology and finest grade of raw material. Also, customization facility is also offered with the products so that customer exact demand can be duly met. Our entire product range is widely appreciated for its lasting performance, zero maintenance, corrosion & abrasion resistance, rugged construction and minimal power consumption. It is being packed in genuine and durable wooden boxes which aids in ensuring safe delivery. Further, client can avail the range at industry leading prices suiting to their pocket size

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator

Employee Count

5

Establishment

2010

Working Days

Sunday To Sunday

GST NO

07AASFM3267H1ZV

Payment Mode

Cash in Advance (CID)

Certification

iso 9001:2015

Explore Related Categories

Seller Details

GST - 07AASFM3267H1ZV

Delhi, Delhi

Partner

Mr Mehtab

Members since

13 Years

Address

L-89, Krishan Vihar, Near Bharat Shakti Public School, Delhi, Delhi, 110086, India

mixing tank in Delhi

Report incorrect details