Multi-layer Pipe Production Line - Pp-r, Pe, Pe-rt, Pe-x Materials | Semi-automatic Operation, 300-500 Kg Capacity, Plc Control

Price Trend: 2000.00 - 200000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | JBD |

| Capacity | 300-500 Kilogram(Kg) |

| Computerized | Yes |

| Automatic Grade | Semi-Automatic |

| Control System | PLC Control |

| Drive Type | Direct |

| FOB Port | Qingdao |

| Payment Terms | Others, Telegraphic Transfer (T/T) |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Packed with plastic film |

| Main Export Market(s) | Middle East, Western Europe, Africa, South America, Asia, Eastern Europe, North America, Australia |

| Main Domestic Market | All India |

| Certifications | CE, ISO9001 |

Product Overview

Key Features

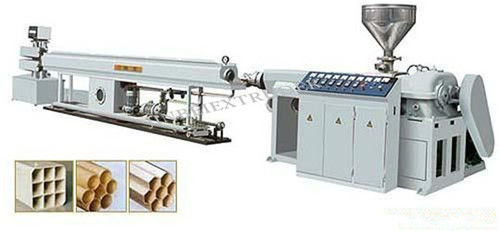

Multi-layer Pipe production line is suitable to produce PP-R, PP, PE, PE-RT, PE-X,PB Multi layer pipes. The line uses three extruder for co-extrusion, adopts PP-R, PE, or PP as main material, the middle layer is glass fiber or other plastics.

Multi-Layer Pipe Production Line The term "domestic device" covers a wide variety of personal applications in a building. These include all types of panels and floor heating systems, which are hot.Cold water facilities and sound insulation drainage.The three characteristics of plastic pipes are important for all these applications, and their relevance depends on the specific application in each case. Both the heating pipe and the hot water pipe must withstand internal pressure and high heat resistance. The piping in the heating system must also be airtight toprevent. Corrosion of metal components through oxygen infiltration and diffusion heating systems to ensure compliance with these requirementsof plastic pipes, PE-X, PE-RT, PP-R, PB and C-PVC have been established as the most suitable materials. The oxygen barrier of the pipe in the heating system is composed of Aluminum barrier in EVOH layer or composite pipe.

These 5-layer pipes with a diameter of 16-63 mm are often used for heating technology, especially for heating applications. The middle aluminum layer is surrounded by two adhesive layers and then the inner and outer layers of PE-X or PE-RT consist. Due to the use of such metal rods, these pipes do not necessarily contain oxygen and other gases, and in the case of PE-X they are also resistant to external ultraviolet radiation and internal chlorine. At the same time, the aluminum layer ensures a high degree of dimensional stability and at the same time the flexibility for small bend radii of the pipe can be simply formed by hand, or it can also be connected by a cold or clamping process. large meeting costs. A special type of composite tube is the so-called "stabilized tube", which is an aluminum-coated PP-R tube with an extruded outer layer to increase its stiffness.

Advantages of this production line:

Customerizing configuration from single-layer, 2, 3, 5 multi-layer pipe structure

2. Single or multiple spiral bodies are provided by multilayer tube material and thickness structure, and appropriate flow path distribution is designed according to the different cavity cavities of the material to ensure the pipe material

3. The thickness of each layer is even, better plasticizing effect

4. Vacuum chamber adopts double chamber design for quick setting

5. According to different multi-layer pipe diameters, high-speed belt traction machine and traction mechanism with multi-track structure and high speed ratio

6. Dual-hydraulic chipless cutting, incision formation

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

2001

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Qingdao, Shandong

Mr Jane Sun

Address

No.15 Guangdong road, Beiguan industrial park, Jiaozhou city, Qingdao, Shandong, 266300, China

plastic extrusion machines in Qingdao

Report incorrect details