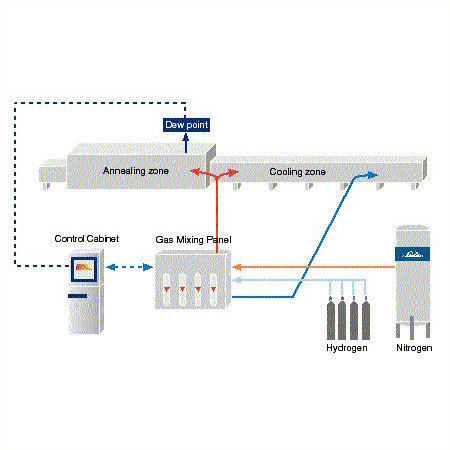

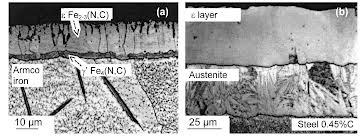

Incepted with desire to attain a distinct niche in this domain, our firm is engaged in providing world-class Nitrocarburizing Services. This treatment enhances the hardness of different types of metals. We use highly advanced resources for providing these services in tune with the needs of our clients so as to gain their optimum satisfaction. Our Nitrocarburizing Services are highly appreciated by clients owing to their cost-effectiveness, timely execution and high reliability.Other details:Nitrocarburizing is a variation of the nitriding process. It is a thermochemical diffusion process where nitrogen, carbon, and to a very small degree, oxygen atoms diffuse into the surface of the steel part, forming a compound layer at the surface, and a diffusion layer. Nitrocarburizing is a shallow case variation of the nitriding process. Advantages of the process include the ability to harden materials which are not prehardened, the relatively low temperature of the process which minimizes distortion, and relative low cost in comparison to carburizing or other case hardening processes. This process is done mainly to provide an anti-wear resistance on surface layer and to improve fatigue resistance.An additional advantage is that nitrocarburizing can be applied to the same materials as is nitriding, as well as unalloyed materials, where good wear resistance and some improved fatigue resistance are needed at a low cost. It is widely used for stampings, as an alternative to hard plating or even carbonitriding. SPECIFICATION DAC SIZE -8 Load Size: 30"W x 48"D x 24"H(700mm x 1000mm x 700mm) Gross Load Weight: 600 Kg. Operating Temp.: 200OC to 1315OC DAC SIZE -13 Load Size: 34"W x 48"D x 30"H Gross Load Weight: 1000Kg. Atmosphere: N2+NH3+LPG Operating Temp.: Upto 750OC Temperature Uniformity: 5OC Controls: PLC based with Scada Heating: Thyristor controlled Cooling: Under Protective Atmosphere with forced gas cooling Material Handling: Motorized Loader/Unloader