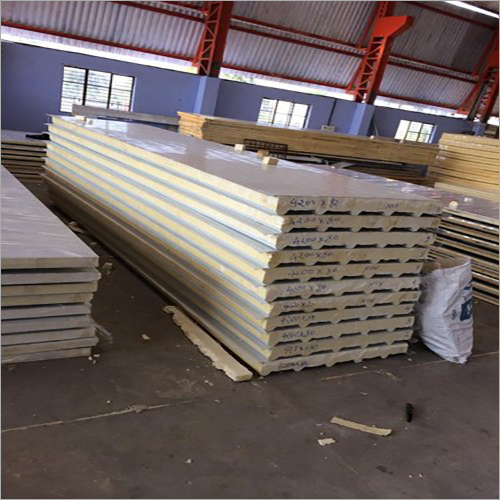

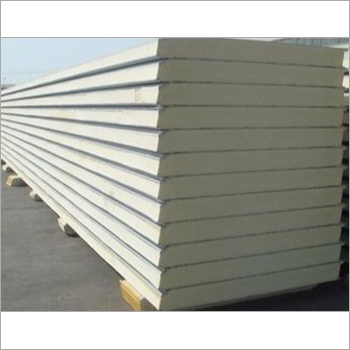

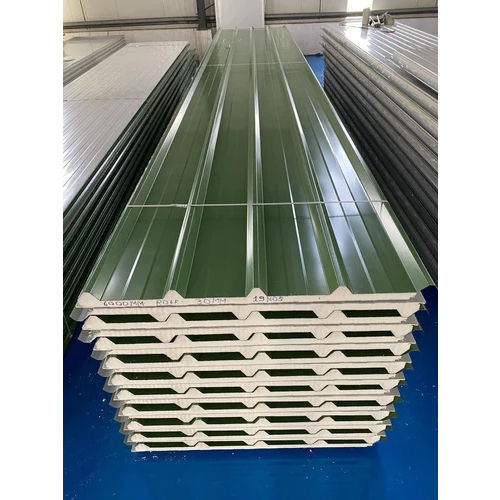

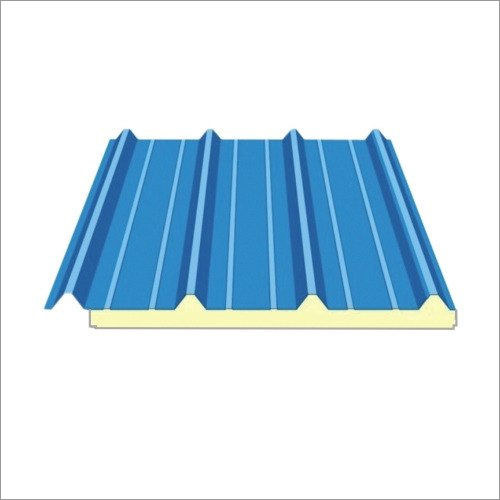

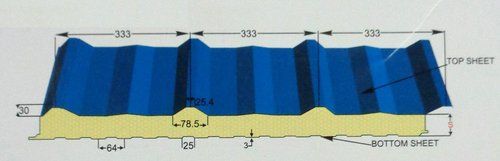

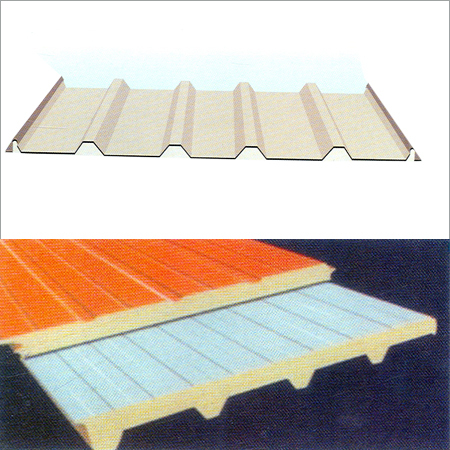

We are renowed as the most coveted manufacturers and suppliers of high quality Sandwich PUF Panels that are widely demanded in the global market for their heat transmitting properties. Our professionals manufacture these panels using premium grade polyurethane polymers and modern techniques in tandem with industry standards. Further these panels are renowned as the preferred choice for roofing and cladding at large industrial buildings refrigerated warehouses office blocks exhibition halls fair pavilions schools and sports halls. Clients can avail these Sandwich PUF Panels from us in different colors patterns and sizes at industry leading prices. Features: Sturdy construction Light-weight Excellent finish Uniform thickness Description:PU/PIR metal-face sandwich panels can be manufactured with the PU/PIR reaction mix is first laid down on one metal facing. During the expansion process rigid polyurethane foam passes through a tacky phase which enables it to form a strong bond with the facings. The insulating effect of PU/PIR foams is much better than that of mineral wool for example a layer of PU/PIR ten centimeters thick has a heat transfer coefficient of around 0.25 W/m2K. A rough estimate of what this difference means in terms of energy consumption can be made based on the example of a factory building. Assuming the building has a floor area of 40X20 square meters and 10 meters high the annual amount of heating oil saved could be roughly 3000 litres if both the walls and the roof are insulated with PU/PIR metal-faced sandwich panels rather than panels of the same thickness based on mineral wool. Low energy consumption also results in an equivalent reduction in carbon dioxide emissions. Industrial Construction of PUF Panels Polyurethane sandwich panels come complete with specially formed tongue-and-groove joints ensuring a fit and maximum integrity. Assembly is fast easy and cost effective. The resultant sandwich panel has a load-bearing capability many times greater than that achieved by adding together the load-bearing capacities of the individual layers. As a result these thin relatively lightweight sandwich panels can safely bridge wide spans. For example a panel just 100mm thick can easily bridge a clear span of some 6 meters.