Shredo Briquetting Machine Dimension(l*w*h): Approx. Diameter (50-100)mm Length 150 Mm Millimeter (Mm)

Price:

Get Latest Price

In Stock

Product Specifications

| Dimension (L*W*H) | Approx. Diameter (50-100)mm Length 150 mm Millimeter (mm) |

| Shape | Briquette |

| Payment Terms | Paypal, Others, Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | On Order Per Day |

| Delivery Time | 12-16 working Week |

| Main Export Market(s) | Australia, South America, Western Europe, Middle East, Asia, Eastern Europe, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

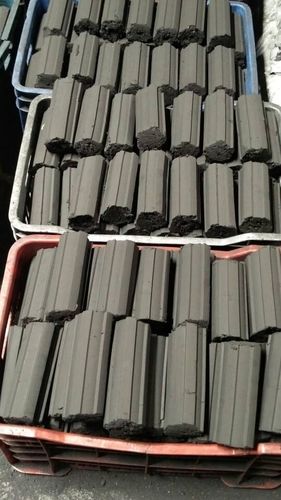

Briquettes are generally 50-80 mm diameter and 150 mm length waste-paper cylinders compressed at a high temperature, with a moisture content ranging between 8 to 15%. In some cases, they have holes in order to improve their combustion. Briquettes may be composed of crushed and high density wood or composed of crushed, dried and moulded charcoal, under high pressure. Briquettes are generally used as fuel for the furnaces & boilers etc. They possess a good calorific value & it also depends upon the material too e.g. briquettes formed by shredding the waste papers is having the good caloric value as compared to the briquettes formed by the municipal solid waste.

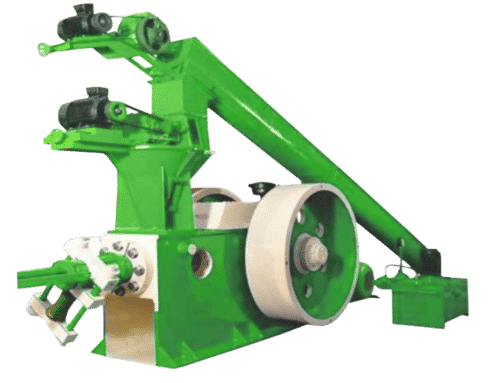

Briquetting Process

Briquettes are manufactured by compressing and compacting the shredded waste currency papers, forestry, agricultural or industrial origin raw material, Natural compaction of the raw material is achieved by compressing at high pressure, which produces an increase in temperatures leading to a divided into smaller surface, which gives a glossy appearance and consistency to the briquettes. The typical briquette production process includes the following stages:

a) Pre-shredding

b) Final Shredding

c) Briquetting

When the material passes through the process of final shredding then it becomes more densified as compared to after the pre-shredding. When it becomes densified then it is compressed at high pressure to achieve the final output as briquettes.

Company Details

Since its inception in 1975, SERVO INTERNATIONAL (SERVO) - an amalgamation of expertise, resources, opportunities and engineering excellence has embarked on a mission to serve the global industry by manufacturing various spare parts of Shredder Machines and meeting stringent quality demands of clients in India and abroad. Shredder Parts, i.e. Industrial Knives, Shredder Knives, Shredder Blades, Tire Shredders, MSW Shredder / MSW Shredding Machine etc., supplied by us have been liked and appreciated by all our valuable clients to their utmost satisfaction. We are a trusted manufacturer, exporter and supplier in this domain. Reliability and unique standard of our products, proper processing, services, manpower with updated technical know-how, latest machinery, timely fulfillment of our commitments and trustworthy support service - all to the entire satisfaction of our thousands of customers across the world have been the vital ingredients that have earned us their confidence. Best technology, top class raw materials and clear thinking have shaped SERVO into a customer-friendly organization, fully geared to meet their techno-economic requirements of Recycling Machine Blades, Industrial Shredder Blades, Tire Shredder Blades and EFB Shredder Blades etc. The company believes in creating long term relationship with customers on mutual benefit basis through close interaction, based on uncompromising product quality and competitive lowest prices.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1975

Working Days

Monday To Sunday

Payment Mode

Cash Advance (CA)

Related Products

Explore Related Categories

Seller Details

Ludhiana, Punjab

Marketing Director

Mr. Yuvraj Bhandari

Address

Servo Building, Plot No. 4012, Phase - II, Dugri, Ludhiana, Punjab, 141013, India

briquetting machines in Ludhiana

Report incorrect details