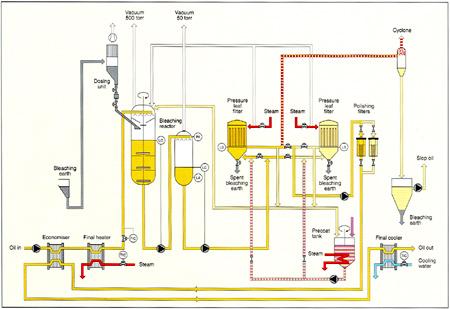

Wet Bleaching Process

Price:

Get Latest Price

In Stock

Product Specifications

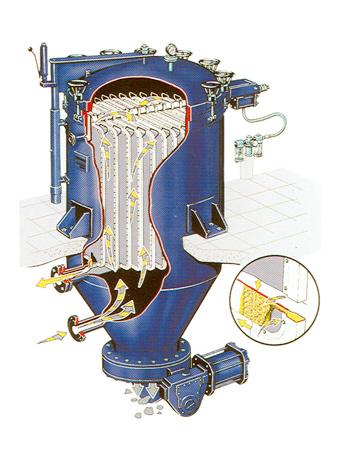

| Reactor Type | Vertical |

| Reactor Material | Stainless Steel |

| Filter Type | Pressure Leaf |

| Vacuum Level | Medium |

| Water Content | 0.5% |

| Steam Pressure | Variable |

| Cyclone Type | Horizontal |

| Features | Efficient Bleaching, Cost Effective, Reduced Earth Use, Improved Filtration, Oil Recycling, Soap Removal, Lower Oil Loss |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, RITIKA CONSULTANTS has a pan-India presence and caters to a huge consumer base throughout the country. Get Plant & Machinery from RITIKA CONSULTANTS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

5

Establishment

2004

Related Products

Explore Related Categories

Seller Details

New Delhi, Delhi

Accepts only Foreign inquiries

Ceo

Mr. Nalini Ranjan

Address

Building No. 2nd Floor, B-365, C R Park, New Delhi, Delhi, 110019, India

Report incorrect details