Control Valves

(3429 products)Y Type Control Valve - Supreme Grade Quality Components | Reliable Vendor Sourced Manufacturing, Industry Norm Compliance

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Powder Coated Industrial Control Valve Size: 2 Inch To 48 Inch

Price: 150000 INR/Unit

MOQ1 Unit/Units

ApplicationOil and Gas, Power Generation, Water Treatment, Chemical Processing

UsageUsed in various industrial processes to regulate the flow rate, pressure, temperature, or level of a fluid

ConnectionOther

Product TypeControl Valve

Size2 to 48 Inch

MaterialStainless Steel, Plastic, Casting, Alloy, Brass, Forged, Rubber, pvc, upvc, Wood, Carbon Steel, PP-R, Ductile Iron, Nylon, Aluminum, Ceramic, Other

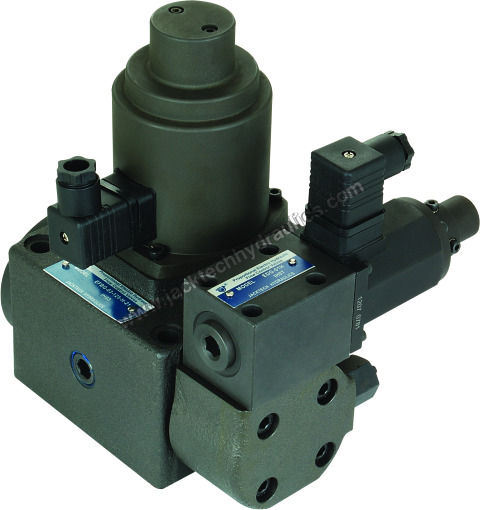

Compensated Proportional Valve - Material: Forged

Price: 35000 INR/Unit

MOQ10 Unit/Units

UsageIndustrial

SizeDifferent available

SealingSealed

MaterialForged

Port SizeCustomized

Pipe Connection TypeSocket

Suyojan Hydromechanical Systems Private Limited

Vasai

Cast Iron Hydraulic Pressure Relief Flow Valves

Price: 35000 INR/Piece

MOQ1 Piece/Pieces

SizeEFBG 03 and EFBG 06

Product TypeHydraulic Pressure Relief Flow Valves

UsageIndustrial

StructureCheck

MaterialCast Iron

PowerHydraulic Watt (w)

Control Valves - Material: Stainless Steel

Price: 17000.00 INR/Piece

MOQ1 , Piece/Pieces

UsageIndustrial

Product TypeControl Valves

Size1/2 to 12

MaterialStainless Steel

MediaWater

PowerElectrical

Casting Pneumatic Control Valve

MOQ10 Unit/Units

UsageIndustrial

SizeDifferent Sizes Available

MaterialCasting

Pipe Connection TypeFlange Type

Pressure Relief Valve - Stainless Steel | High Durability, Precise Pressure Control, Reliable Flow Management

Price: 500 INR/Piece

MOQ1 , Piece/Pieces

Supply Ability1000 Per Month

Delivery Time1 Months

Grey 2/2 & 3/2 Way Diaphragm Type Control Valves

Price Trend: 5000.00 - 50000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeControl Valves

UsageFor Control liquid

MaterialStainless Steel

MediaWater

Weight100-150 Grams (g)

ColorGrey

High Strength Pressure Relief Valve

Product DescriptionSkywin make cast carbon steel, angle type design, spring loaded, pressure relief valve flanged end to 150 class, suitable for air, water, gas, crude oil.\015\012\015\012Application: Industrial\015\012Construction: Strong\015\012Corrosion Resistivity: High

Program Control Valves

MOQ5 Unit/Units

Product TypeProgram Control Valves

ApplicationIndustrial use

ColorWhite, Blue

Pressure Control Valve - High Temperature, Hydraulic Power | Durable Performance for Reliable Fluid Management

Price: 45000 INR/Piece

MOQ1 Piece/Pieces

TemperatureHigh Temperature

PowerHydraulic

Idle Control Valve

Product DescriptionOur clients can avail from us a qualitative assortment of Idle Control Valve which is manufactured, supplied and exported us from Jamnagar, Gujarat, India. These are made by high grade of material. These are according to the client specification.\015\012Specification:\015\012Product Name- air contro

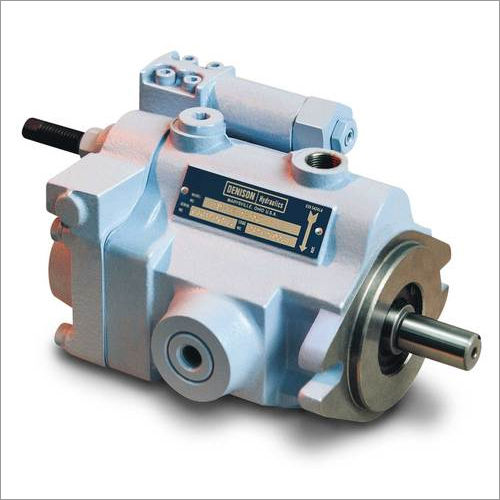

Cast Iron Aber Pv Pvb Gear Pumps With Integrated Valve

Price: 80000 INR/Piece

MOQ1 Piece/Pieces

Product TypeABER PV PVB Gear Pumps With Integrated Valve

Weight20 Kilograms (kg)

UsageIndustrial

StandardHigh

MaterialCast Iron

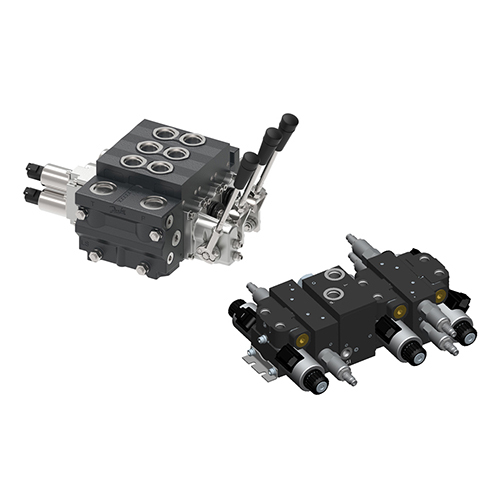

Industrial Mobile Control Valve - High-Grade Engineering | Safe for Industrial Use, Trustworthy Performance Across Various Industries

Payment TermsOthers, Telegraphic Transfer (T/T)

Delivery Time2 Week

Sample PolicyContact us for information regarding our sample policy

Hydraulic Control Valves

Price Trend: 7000.00 - 20000.00 INR/Piece

MOQ10 Piece/Pieces

Supply Ability1 Per Month

Delivery Time1 Months

Mahavas Precision Controls Private Limited

Pune

Trusted Seller

Trusted Seller7 Years

Brass Control Valve - 375 Grams | Industrial & Commercial Use, Corrosion Resistant, High Efficiency, Easy to Install

MOQ200 Piece/Pieces

Product TypeControl Valve

Weight375 Grams (g)

UsageIndustrial & Commercial

ColorSilver

StandardHigh

MaterialBrass

Elevator Flow Control Valve - Stainless Steel, 10-125 l/min Flow Range, 5-100 bar Pressure Range, 5 kg Weight, Black Finish | Blain Hydraulics

Payment TermsCash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

Delivery Time25-30 Days

Sample AvailableYes

Ksd Equipments Private Limited

Ahmedabad

Trusted Seller

Trusted Seller6 Years

Proportional Control Valves - Cast Iron, 5000 psi Maximum Pressure | Industrial Application, Low Maintenance, Long Functional Life

Price: 78000.00 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Piece/Pieces

ApplicationIndustrial

MaterialCast Iron

TemperatureNormal Temperature

MediaOil

StructureControl

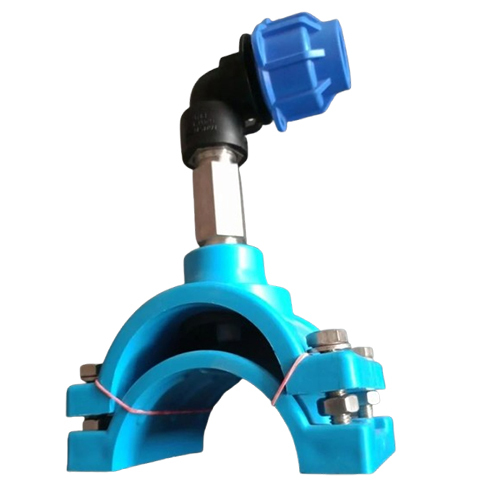

Ss Water Flow Control Valve Application: Industrial

Price: 46.0 INR/Unit

MOQ250 Pieces

UsageHOUSE WATER CONNECTION

Weight125 Grams (g)

ApplicationIndustrial

ColorSilver

Length71 Millimeter (mm)

SizeDifferent SIZE

Earth Water Pipe Fittings Private Limited

Rajkot

Flow Control Valve Color Code: White

Payment TermsOthers, Cash Against Delivery (CAD), Telegraphic Transfer (T/T)

New 220 Volt Brown Gas Pressure Relief Valve - 12mm Size, Polished Casting Material | Durable Heat Sealing, Low Temperature, 3 Inch Length, Thread Connection

Price: 12000 INR/Piece

MOQ4 Piece/Pieces

UsageRelieve Over Pressure Function

Width4 Millimeter (mm)

Voltage220 Volt (v)

ColorBrown

Length3 Inch (in)

ConnectionThread

Boiler Steam Control Valve - Color: Grey

Price: 2000 INR/Unit

MOQ1 Unit/Units

SizeDifferent Size

ApplicationSteam

UsageIndustrial

ColorGrey

StandardHigh

MaterialCast Iron

Solenoid Control Valve - High-Quality Raw Material | Durable Design, Reliable Performance

Product DescriptionWe are Bengaluru, Karnataka, India situated one of the most reliable names actively engaged in exporting, trading and supplying a superior quality array of Mining Shank Adapter. The Solenoid Control Valve offered by us is sourced from the highly acclaimed vendors of the industry who design and manu

Aira Trex Solutions India Private Limited

Bengaluru

Stainless Steel Control Valve - Manual Operation, Powder Coated Finish, Various Port Sizes, Long Life Functionality

Price: 8000 INR

MOQ1

Port Sizevarious sizes are available

Motorized Control Valve - Sealing: Sealed

Price: 31500 INR/Piece

MOQ1 Piece/Pieces

Product TypeMotorized Control Valve

UsageIndustrial

SealingSealed

StandardHigh

MaterialOther

MediaWater

Direction Control Valve - Aluminum, Different Sizes Available, Black Color | Electrical Power, High Temperature Operating Capability

Price: 8000 INR/Unit

MOQ1 Unit/Units

Product TypeDirection Control Valve

UsageIndustrial

SizeDifferent Available

ColorBlack

MaterialAluminum

TemperatureHigh Temperature

Stainless Steel Pressure Reducing Control Valve - Semi-Automatic, Horizontal Mounting Style, Blue Color | Optimized for Water, Oil, Gas Applications

Price: 80000 INR/Piece

MOQ5 Piece/Pieces

ColorBlue

UsageWater/Oil/Gas

Product TypePressure Reducing Control Valve

ApplicationWater/Oil/Gas

MaterialStainless Steel

MediaOthers, Water/Oil/Gas

Foot Valves Flanged End Application: Industrial

MOQ50 Piece/Pieces

Product TypeFlanged End Valve

ColorWhite

ConnectionFlange Type

ApplicationIndustrial

Pipe Connection TypeFlange Type

Latest From Control Valves

Cast Iron Direction Control Valves

By:

Qualitech Industrial Products

Load sensing directional control valves

By:

Suyojan Hydromechanical Systesms Private Limited

Ready To Ship Control Valves

What is Control Valves?

Control Valves are designed for regulating the rate of fluid flows which happen as a result of positioning the valve by changing the actuator. In valves, an actuator is a handle that can be manual-operated or power-operated. Control valves are manufactured for near precise controlling of the flow of liquid or gas in a piping system. It is done by maintaining predetermined set points which are flow rate, temperature, and pressure. Control valves also control the product parameters, such as density, liquid level, concentration, and other factors.

Control Valves consist of the main body, positioner, actuator, and accessories. The valve body comprises a bonnet assembly and trims parts. The design of the control valves are so developed that they can withstand differential pressure and fluid static pressure. It permits fluid flow, ensures pipe-connecting ends, and assists the seating surface as well as a valve closure component. Actuators could be manually-operated or power operated. In manual operation, two types of actuators are used: hand lever and gearbox. In the power-operated type electric, a hydraulic and pneumatic actuator is used. The positioners in the valve monitor and control the actuator movement to maintain the flow rate, temperature, and pressure at set points. In control valves, the accessories are pressure regulators, electro-pneumatic transducers, position indicators, limit switches, and handwheels.

Control Valves are mainly used for controlling the flow of liquid, gas, and slurries. These are designed for use in:

- Pipeline

- Oil & Gas plants

- Marine industry

- Food & beverage plants

- Pulp and paper mills

Some Common Types of Control Valves

Following are some common types of control valves based on their operations:

Sliding stem

- Globe valve – Flow control device

- Angle body valve

- Angle seat piston valve

- Axial Flow valve

Rotary

- Butterfly valve – Flow control device

- Ball valve – Flow control device

Other

- Pinch valve

- Diaphragm valve – Flow control device

Components of Control Valve

Here are the main components of control valve:

-Body

It is a specific kind of pressurised container that has either an aperture or an opening. The controlled liquid is let to pass through the body of the valve as it is opened and closed. Monitoring the behaviour of the flow regulation is made easier as a result.

-Trim

In addition to the body, the trim is another component of the valve that has direct contact with the fluid being controlled. It is made up of the stem, as well as the seat, disc, and plug.

-Actuator

To give the necessary force to operate the control valve, it is made up of electric or pneumatic mediums to transmit the force.

-Bonnet

The bonnet serves as a mounting point for the control valve guide and the actuator, as well as a channel for the stem to move through. The guide, the packing, the packing nut, and the centrepiece are the components that make it up. Between the bonnet and the stem is a piece of packing that serves as a kind of fastening. It contributes to the prevention of any leakage.

-Seat and Disk

The disc is the third principal pressure boundary for a bonnet-style valve. The disc allows you to control whether or not fluid may pass through it. When the disc is closed and the outlet side is depressurized, the entire system pressure is transferred across the disc.The disk's ability to maintain pressure is why it's so important. To improve their durability, discs are often forged and, in some designs, given a hard surface. In order to provide a tight seal when a valve is closed, the seating area of a disc must have a smooth surface finish. The shape of the discs on most valves is reflected in their names.

Control Valve Flow Characteristics

Each type of control valve has its own unique flow characteristic that specifies the relationship between "valve opening" and flow rate at a given pressure. Valve opening here means the distance between the valve plug and the valve seat when the plug is in its closed position. The orifice pass region is not being discussed here. The orifice pass area, also referred to as the "valve throat," is the smallest opening between the valve plug and seat. No matter how a valve is described, there is a constant one-to-one relationship between flowrate and orifice pass area.

When the volumetric flowrate and differential pressure through a valve are both constant, the orifice pass area will be the same regardless of the valve size or inherent flow characteristic. However, for the same pass area, different valve characteristics will result in different 'valve openings.

When comparing linear and equal percentage valves, a linear valve's valve opening might be 25% for a given pressure drop and flowrate, while the corresponding value for an equal percentage valve might be 65% under the same conditions. The passageways through the orifices won't change. The trim, or actual shape of the plug and seat combination, is what determines the degree to which these valves open and close. For both globe valves (where the plug moves up and down with respect to the seat) and rotary valves, the term "valve lift" is used to describe the opening motion lateral movement of the plug relative to the seat.

In general, rotary valves like ball and butterfly valves have the same basic characteristic curve, though this can be altered by making small adjustments to the plug for the ball or butterfly valve.

Different Flow Characteristics of Control Valves

-Linear

If, under ideal conditions of constant valve pressure drop, a straight line can be drawn from the flowrate F (or % F, or Cv or % Cv) to the percentage of travel m (or Z for opening position), then the control valve is said to be linear (DPV). As a result, for a fixed valve pressure drop, an increase in travel or opening m results in the same change in flow F (or Cv) (DPV). dm = k dF, where k is a proportional constant, where m is the distance travelled and F is the flow rate.

-Fast Opening

Its flow rate, or Cv, increases exponentially from its starting, small opening to its maximum, large opening. Benefits of the Valve Upgrade Using Kv for modulating control in the start or bottom portion of the trip position is not possible. After that initial steep portion, the flowrate rarely rises as a function of valve opening m. Therefore, such a control valve can only be used in ON-OFF service or in applications where a quick initial release or discharge of flow is required.

-Modified Parabolic

Besides the more frequent Linear and Equal% characteristics, there is also a less common kind called "modified parabolic," which provides excellent throttling action at low valve travel (like Equal%) and an almost linear characteristic for the upper section of flight.

Below the Linear characteristics, the so-called hyperbolic characteristics appear as a "bowed" rectangular plot. Quick-Opening and modified parabolic characteristics are listed primarily for completeness, as Linear and Equal% characteristics can satisfy virtually any control need.

-Inherent Control Valve Flow

When the pressure drop across the control valve is held constant, only then can the manufacturer declare the flowrate to valve travel position connection known as the Inherent valve characteristics. To emphasise, a nearly constant pressure drop across the control valve is only possible if the pressure drop in the piping system is localised to the valve itself, rather than being spread out along the pipeline.

-Installed Control Valve Flow

One that controls the pressure The installed characteristics define the link between the cubic flow rate through into the valve and the valve trip or opening position as the valve is opened from the closed to a varied degree of opening.

What Is Pneumatic Flow Control Valve?

A pneumatic flow control valve is used to regulate the flow of pressurised air across a larger pneumatic system. This valve can either permit or prevent the flow of pressurised air, the force of which is subsequently applied to the operation of a device. Since valves can have any number of inlets and outlets, they can create a wide range of airflow configurations. Valves are categorised according to the number of ports that they have and the flow patterns that they generate.

In addition, given their ability to move air in a number of different ways, they are adaptable to a wide range of applications. Other types of valves, such as pressure regulators, venting-type regulator valves, and needle valves, are designed to fulfil functions that are more specialised than those served by directional control valves, which are the most prevalent form of control valve. Pressure valves or venting-type valves help regulate pressure in a pneumatic air pressure, while needle valves regulate flow.

The Use of Control Valves In Hydraulic Systems

It's not uncommon to see hydraulic power systems in automobiles and aircraft machinery. They have a high power-to-weight ratio and are capable of being put into a resting state, working in bursts, and even reversed. They have lightning-fast reflexes and movement. Fluid control devices not only provide consistent operating levels, but they can also be very long term, which is a major selling point. While some hydraulic equipment can function with a variety of valve configurations, the vast majority requires a dedicated valve.

1. Hydraulic Flow Control Valve

The liquid or gas flow through the system can be monitored and adjusted using the flow control valves. Those valves are designed to improve the hydraulic system's performance to its full potential. Flow control valves are employed for monitoring and adjusting pressure swings in a given system.

2 Pressure Controlling Hydraulic Valve

Pipelines are less likely to leak or explode when the hydraulic pressure is reduced. Pipeline fluid pressure is constantly being measured via pressure control valves. These valves automatically hold the pressure setting that the user has set manually. Counterbalance valve, pressure lowering valve, Hydraulic pressure relief valve, and series valve are some of the several types. A complicated mechanism and series valve power, the counterbalance valve can detect extremely high pressure. One of the most fundamental functions of a pressure relief valve is to return any pressure above the present limit to the storage tank.

3. Direction Controlling Valves

Controlling the release of fluids from the system is accomplished with the help of Direction control valves. Fluid flow can be halted and restarted with these valves. They can usually redirect the flow of the fluid. Multiple lateral control valves, such as a spool valves, prefill valve, test valve, etc., are employed to ensure enough fluid flow within the apparatus. The test and the prefill valves are examples of non-return valves. In order to regulate the pressure in the supply system, control valves are installed. Reduced water loss due to leaks is one of the many benefits of using automatic control valves for pressure and flow management. Safer plumbing with less chance of water hammer and broken pipes.

Best Quality Control Valves available online with price

Buyers interested in buying Control Valves in different types as per their requirements may check the vast availability of all types of control valves. They can check every detail, specification, price, type, dimensions, and their specific applications on different eCommerce platforms. They can connect with control valves manufacturers and suppliers listed at reputed B2B portals for fulfilling their demands.

Buyers interested in buying control valves in bulk quantity should check the features and other details, such as:

-Quality standards

-Material of construction

-Service life

-Product durability

-Minimum order quantity

-Price

-Available stock

-Delivery time

Buy Control Valves Online

Buying Control Valves has become so easy with different B2B marketplaces unveiling a large collection of Control Valves of all types and dimensions. Buyers interested in purchasing in bulk quantity may send all their demands to listed manufacturers at online marketplaces.

Buyers can also take a look at sub-categories available here:

-Pneumatic Angle Type Control Valve

-Hydraulic Control Valve

-Ptfe Lined Globe Control Valve

-Y Type Control Valve

-Actuated Valves

-Direction Control Valves

-Pressure Control Valve

If you are interested in buying control valves, get the contact details of the sellers and send them your requirements.

FAQs: Control valves

Q. What is a control valve and used for?

Ans. A control valve is a device that regulates the flow of a fluid, such as water, gas, or steam, through a pipe or system. It is used to control the pressure, temperature, and flow rate of the fluid.

Q. How does a control valve work?

Ans. Control valves work by adjusting the flow of fluid through the valve. This is typically done by a valve actuator, which moves a valve element, such as a ball, disc, or diaphragm, to change the flow rate. The valve element is typically connected to a control signal, such as a pressure or temperature sensor, which tells the valve how to adjust the flow rate.

Q. What is an actuator in the control valve?

Ans. An actuator is the main component that starts, stops, or throttles the flow of media in a pipeline. It can be hand-operated or power-operated, such as electric, pneumatic and hydraulic.

Q. What is the difference between a control valve and a ball valve?

Ans. A control valve is a linear motion valve whereas a ball valve is a quarter-turn valve similar to a butterfly valve.

Q. What is the main purpose of a control valve?

Ans. A control valve precisely controls the flow of media in a pipeline. It has a mechanism to set points against flow rate, pressure, and temperature.

Q. Where can buyers purchase control valves?

Ans. Buyers can check the range available at the trusted B2B marketplace where they can connect with several manufacturers and suppliers to fulfilling their requirements.

Q. What is a pneumatic actuator in a control valve?

Ans. A pneumatic actuator uses compressed air pressure to set the actuator in a controlled motion to turn the valve for opening, closing, or throttling the flow of media.

Q. What are the different types of control valves?

Ans. There are many types of control valves, including globe valves, ball valves, butterfly valves, diaphragm valves, and more. Each valves has its own unique features and characteristics and is best suited for specific applications.

Q. What are the benefits of using control valves?

Ans. Control valves offer many benefits, including precise control of fluid flow, improved system efficiency, and the ability to maintain a safe and stable operating environment. They also can help in reducing pressure and temperature fluctuations, and preventing system damage.

READ MORE BLOG:

- India's Best Quality Top 10 Control Valve Manufacturers, Suppliers & Exporters

- Top 10 Air Valves Manufacturers, Suppliers & Exporters in India

- Butterfly Valves Manufacturers, Suppliers & Exporters In India - 10 Best

- Best Ball Valves Manufacturers, Suppliers & Exporters in India

- Top 10 Gate Valves Manufacturers, Suppliers, Exporters in India

- Top 10 Finest Quality Globe Valves Manufacturers, Suppliers & Exporters in India

- Top 10 Highest Grade Industrial Valve Manufacturers, Suppliers & Exporters in India

- Top Notch Rotary Valves Manufacturers & Suppliers in India

- Stainless Steel Valves Manufacturers Suppliers Exporters in India: Complete List

Manufacturers & Suppliers of Control Valves

Company Name | Member Since |

|---|---|

Dynamic Enterprises Inc. Pune, India | 16 Years |

Joy Krishna Engineering Works Howrah, India | 15 Years |

Shri Shyam Hydraulics Indore, India | 15 Years |

Bhargav Brass Industries Jamnagar, India | 14 Years |

Jacktech Hydraulics Ahmedabad, India | 13 Years |

Ally Hi-Tech Co., Ltd. Chengdu, China | 12 Years |

Asva Corporation Ahmedabad, India | 10 Years |

Asten Controls Llp Ahmedabad, India | 9 Years |

Mahavas Precision Controls Private Limited Pune, India | 7 Years |

Uflow Automation Rajkot, India | 6 Years |

Popular Products