Nickel Alloy

(967 products)Hastelloy X Buttweld Fittings Chemical Composition: B 0.01

Price: 1899 INR/Kilograms

MOQ300 Kilograms/Kilograms

ColorBlack, Silver

Product TypeNickel Alloy

ShapeOther

Elongation4o %

StrengthTensile Psi 1,10,000, Yield strength Psi 51000

GradeASME ANSE B 16.9

Mar-M 002 Nickel Super Alloy - High Strength, High Temperature | Industrial Grade, Gray, Casting, Fastener, Military Applications, Available in Various Shapes

Price: 5000 INR/Number

MOQ1 Number

ColorGray

Product TypeNickel Alloy

ShapePowder, Bar, Pipe, Plate, Stripe, Wire, Square, Other

HardnessHigh Strength

GradeIndustrial Grade

ApplicationMilitary, Other , Casting, Fastener

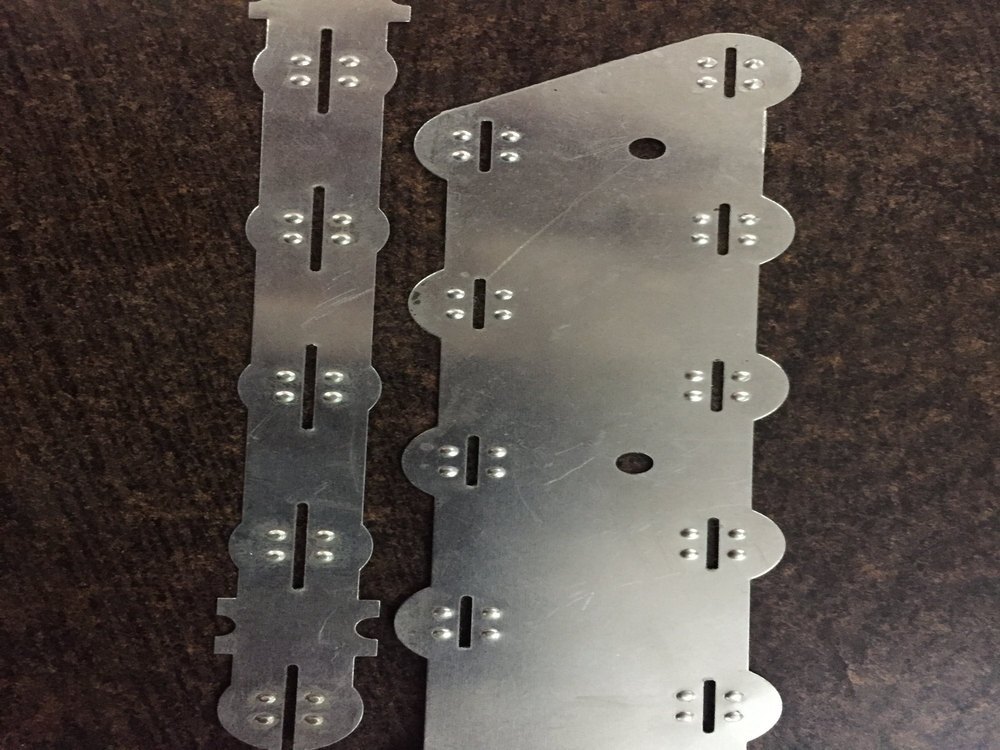

Silver Nickel Sheets

MOQ01 Unit/Units

Product TypeNickel Alloy

GradeIndustrial

ColorSilver

Nippen Tubes

Mumbai

Trusted Seller

Trusted Seller9 Years

Nickel Alloys Sheet - N02200, N02201, N04400, N05500, N06600, N06625, N08810, N08825, N06022, N10276, N10665 | First Class Quality, Rigid Hardness, Stripe and Wire Shapes

Price Trend: 1000.00 - 4000.00 INR/Kilograms

MOQ100 Kilograms/Kilograms

ShapeStripe, Wire

HardnessRigid

GradeFirst Class

ApplicationCasting

Monel K 400 Nickel Alloy Metal

Product DescriptionWe take enormous pleasure to present ourselves as the noticeable manufacturer, exporter, distributor and supplier of Monel K 400 Nickel Alloy in Ahmedabad, Gujarat, India. Our provided alloys are manufactured by using optimum grade raw material and ultra-modern technology in tune with industry set p

Nickel Metal Plate Grade: 99%

Price: 1150 INR/Kilograms

Product TypeNickel

ShapePlate

Grade99%

Nickel Bronze - Application: Construction

Price: 250 INR/Piece

MOQ10 Piece/Pieces

Product TypeNickel Alloy

ShapeBar

GradeNickel 200, Nickel 201

ApplicationConstruction

Colorsliver

Nickel Alloy Round Bar - Application: Construction

Price: 3200 INR/Kilograms

MOQ100 Kilograms/Kilograms

ShapeBar

HardnessRigid

GradeIndustrial

ApplicationConstruction

ColorSilver

Gurudev Tubes (india)

Mumbai

Trusted Seller

Trusted Seller1 Years

Electric Battery Nickel Strips - Application:

Price: 5000.0 INR

MOQ5

ColorSilver

HardnessHard

GradeNi-200/201

Chemical Composition99.5% NICKEL

Applicationn, i, n, d, ], t, c, I, ', O, h, e, u, s, t, t, [, ', E, l, e, c, r, o, , r, y, ', ,, , r, , '

Plain Nickel Sheet - Color: Silver

Price: 300 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

ShapePlate

ElongationNormal

StrengthHigh

GradeSS316 L

Nickel Rods - Premium Quality Nickel Material, Superior Defect-Free Manufacturing Standards

Product DescriptionWe are one of the reputed organization engaged in providing superior quality nickel rods. These products are supervised at every stage of production, in order to eliminate defects and maintain high standards of quality. For more details contact us

Nickel 200 Plate - Color: Silver

Price: 2300 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeNickel Alloy

StrengthHigh

HardnessRigid

GradeMultiple Grades Available

ColorSilver

Jicon Steel India

Mumbai

Trusted Seller

Trusted Seller2 Years

201 Nickel Steel Sheet - 99% Nickel Composition, 1250°F Temperature Resistance | Customized Shape, Long Service Life, High Melting Point of 2635°C

Price: 210 INR/Kilograms

MOQ50 Kilograms/Kilograms

Steel TypeStainless Steel

Steel Product TypeSteel Sheets

ShapeCustomized

Nickel Alloy Sheet and Plate

Price: 3000 INR/Kilograms

MOQ20 Kilograms/Kilograms

Product TypeNickel Alloy

ShapePlate

GradeA

ColorMetallic Silver

Crack Resistance Industrial Nickel Plates

ShapePlate

HardnessYes

ResistanceRust

ApplicationConstruction

ColorSilver

Uns N02200 Nickel Alloy 201 Plates - Application: Construction

Price: 4200 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeNickel Alloy

ShapePlate

StrengthHigh

HardnessRigid

Grade201

ApplicationConstruction

Nimonic Foils

Price: 4000 INR/Kilograms

MOQ1 Kilograms/Kilograms

Product DescriptionNimonic Foils

INCONEL RING GASKET

Price: 1000 INR/Kilograms

MOQ10 Kilograms/Kilograms

Product DescriptionINCONEL RING GASKET

High Grade Buttweld Fittings - Carbon Steel, High Quality, Coated Surface, Sleek Silver Finish | Ideal for Bearings Applications, Exceptional Durability

MOQ100 Piece/Pieces

Product NameStainless Steel Products

Steel TypeCarbon Steel

GradeHigh quality

SurfaceCoated

ApplicationBearings

ColorSilver

Silver Round Molybdenum Rod

Price: 5000 INR/Kilograms

MOQ50 Kilograms/Kilograms

GradeDifferent Available

ColorSilver

Product TypeMetal Products

ShapeBar, Bar

SizeDifferent Available

WarrantyYes

Shree Kailaji Alloys Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller2 Years

Plain Nickel Sheet - SS316 L Grade, Silver Color, High Hardness for Versatile Applications in Roofing, Cladding, Flooring

Price: 250 INR/Kilograms

MOQ10 Kilograms/Kilograms

Product TypeNickel

HardnessYes

GradeSS316 L

ApplicationConstruction

ColorSilver

Nickel Alloy Round Bar - Silver Finish, Hardness Rated for Construction Applications

Price: 3200 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product TypeNickel Alloy

ShapeBar

HardnessYes

ApplicationConstruction

Nirvaan Overseas

Mumbai

Trusted Seller

Trusted Seller2 Years

Nickel Metal Rod - Ni 99.5 Min, C 0.03 Max, S 0.020 Max | High Strength, Rigid Hardness, Corrosion Resistant, Versatile Application in Industrial Processes

MOQ100 Kilograms/Kilograms

Product TypeNickel Alloy

ElongationNormal

StrengthHigh

HardnessRigid

GradeMultigrade

ApplicationCasting, Construction

Nickel Products

Price: 1900 INR/Kilograms

MOQ100 Kilograms/Kilograms

Supply Ability1000 Per Week

Delivery Time3 Days

Artic Steel Industries

Mumbai

Trusted Seller

Trusted Seller2 Years

Hastelloy Pipes - Industrial Grade, Corrosion Resistant and High Durability for Pharmaceutical, Agricultural, Food, Petrochemical, and Power Industries

Price Trend: 1500-3000 INR/Kilograms

MOQ200 Kilograms/Kilograms

GradeIndustrial

ApplicationConstruction

N02201 Nickel Sheet Application: Construction

MOQ100 Kilograms/Kilograms

Product TypeNickel

HardnessRigid

GradeDimension Standard -JIS, AISI, ASTM, GB, DIN, EN, etc

ApplicationConstruction

ColorSilver

Hastelloy Plates - Nickel Alloy, Industrial Grade Square Shape, Silver Color

Price Trend: 2500.00 - 6000.00 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeNickel Alloy

ShapeSquare

GradeIndustrial

ColorSilver

Latest From Nickel Alloy

Ready To Ship Nickel Alloy

Nickel Alloy: Expensive & Corrosion-resistant Alloys

Nickel is an adaptable element that can form alloys with a wide variety of metals. Alloys that contain nickel as their primary component are known as nickel alloys. Nickel and copper both have complete solubility in solid form in each other.

Nickel, chromium, and Iron all have rather wide solubility ranges, which allows for a wide variety of alloy combinations.

Thanks to its high adaptability and excellent resistance to heat and corrosion, it is used in a wide variety of contexts. It is widely used in the energy and nuclear power industries, for example in gas turbines for airplanes and power plants.

Nickel is a ferromagnetic metal element that possesses great qualities such as resistance to corrosion, high temperature resistance, oxidation resistance, and strong ductility.

Nickel is also a good conductor of electricity. It finds widespread application in the industries of metallurgy, the chemical industry, aerospace, and many others.

It is an essential component in the manufacturing process of stainless steel, high-temperature alloys, power batteries, and a variety of other materials. It is a vital strategic resource for the metal industry.

Understanding Nickel Alloys

Nickel alloys are a subcategory of alloy steels that are characterised by the presence of Nickelalloys as the major component. Inco is the manufacturer of both Inconel 625 and Hastelloy C276, two examples of nickel alloys. Both of these alloys are made by Inco.

Nickel alloys, in general, are pricey alloys that have a high resistance to corrosion and are used for a range of valve components. Nickel alloys are also utilised in a number of other industrial applications.

Here is a simple way to classify the different kinds of nickel alloys.

1. Nickel-Titanium Alloys

After being distorted at a lower temperature, it will return to its normal shape once it is heated back up to its original temperature. Changes in transition temperatures are possible via manipulation of the composition of the system.

Devices used in medicine and specialised connectors are two examples of such uses. When subjected to significant elastic deformation, the same alloy is able to completely restore its previous shape while retaining its super-elastic ability.

This property has found application in a wide variety of situations, ranging from the frames of eyeglasses to the shock absorbers that safeguard ancient stone buildings from earthquakes.

2. Nickel Chromium-Cobalt Alloys

The incorporation of cobalt and molybdenum into Alloy 617 results in the strengthening of the solid solution as well as an increase in the creep-rupture strength of the alloy.

The incorporation of cobalt into HR-160 results in the material exhibiting remarkable resistance to sulphidation and chloride attack in oxidising as well as reducing environments, in addition to other types of high-temperature corrosion.

3. Nickel Chromium-Molybdenum Alloys

In this group, the material known as Nickel Alloy C-276 stands out as being the most resistant to corrosion that can be found. One of their numerous qualities is an exceptional resistance to reducing acids such as hydrochloric and sulphuric. Other strengths include.

There are many other permutations of this composition, with several adjustments made to the levels of Cr and Mo, and in some cases the addition of Cu or W, to boost the alloy's resistance to corrosion in situations that are more oxidising or reducing, respectively.

This category contains a variety of different materials, including Alloy C-22, Alloy 59, Alloy C-2000, and Alloy 686.

4. Wrought Nickel

Because of its resistance to corrosion, especially in alkaline environments, pure nickel UNS finds application in the chemical sector. It is also a component in transducers and electromagnetic interference shielding.

5. Nickel Iron Alloys

These can be utilised for a variety of purposes, including as the production of soft magnetic materials, the sealing of glass to metal, and the creation of materials with regulated thermal expansion.

Which has 36% nickel and the remainder iron, is remarkable in that its coefficient of thermal expansion is virtually zero at the temperature of the surrounding air.

As a result of this, it is beneficial in applications that need dimensional accuracy, such as precision measuring equipment and thermometer rods. It is also beneficial at cryogenic temperatures due to the fact that its thermal expansion rates are not particularly high.

Nickel Alloys – Characteristics

1. Extremely Harsh Working Environment

There are many applications for nickel-base alloys, including parts that must withstand high temperatures and high pressures, like those found in the gas chambers of space flight enginesstructural components used in the nuclear, petroleum, and marine industries corrosion-resistant pipelines and other similar applications.

2. Nickel-molybedenum-Chromium-Copper Alloys (Illium)

These alloys, which are often cast, are popular among engineers due to their high corrosion resistance. Examples of substances that wrought illium is impervious to include salt water, sulfuric acid, nitric acid, phosphoric acid, and various fluorides.

Wrought Illium's cast equivalent is Illium G. Cast alloy Illium B has excellent resistance to sulfuric acid. In addition, it can be hardened through heat treatment at temperatures between 1,100 and 1,400 degrees Fahrenheit.

3. High Performance

The incredible adaptability of nickel has inspired the creation of a great number of nickel alloys, which have been put to use in meeting the requirements of businesses of varying sizes and operating in a wide range of fields.

Even when subjected to the worst conditions, nickel alloys remain unrivalled in terms of their tensile and tensile-tensile strengths, as well as their reliability.

4. Nickel Copper Alloys (Monel)

These NiCu alloys include great resistance to corrosion, a diverse set of mechanical characteristics, and ready formability. They retain their tensile strength and corrosion resistance even in freezing conditions. However, precipitation-hardened K-500 exhibits a propensity for stress corrosion cracking.

5. High Nickel Alloys & superalloys

These alloys are employed because of their superior resistance to corrosion and high temperatures. Many are chemically similar to austenitic stainless steels, but are heavily alloyed with other elements, including nickel, chromium, and molybdenum, to increase their resistance to corrosion.

In the energy, power, chemical, and petrochemical industries, these alloys are utilized to withstand very corrosive conditions.

Nickel Alloys – Uses

1. Aircraft Gas Turbines

Because nickel alloys provide excellent hardness, wear and erosion resistance, adhesion, corrosion protection, and it is appropriate for applications where stress needs to be minimised, they are mostly used in the aerospace industry to make discs, turbine blades, and other critical parts that go into jet engines. Nickel alloys are also used in a large number of other industries as well.

2. Medical Applications

Because of their favourable combination of strong mechanical qualities, chemical resistance, and biocompatibility, alloys based on nickel find widespread use in the disciplines of implantology and dentistry.

In these two areas of medicine, the alloys of nickel-chromium and nickel-titanium have shown to be the most successful representatives.

3. Steam Turbine Power Plants

Because of its high strength and extended fatigue life, together with its exceptional resistance to oxidation and corrosion at high temperature, nickel-based superalloy is the material that is most commonly utilised in turbine engines.

4. Chemical And Petrochemical Industries

Because of their superior resistance to corrosion, heat, and pressure, stainless steels and nickel alloys are frequently employed in the petrochemical industry.

This is owing to the fact that these materials are extremely durable. They are applicable in virtually all areas of the business, even those that operate at extremely high temperatures.

5. Nuclear Power Systems

Alloys containing nickel that are resistant to heat and corrosion play a significant part in guaranteeing the structural soundness, longevity, and optimal operation of nuclear power plants over the long term.

They have use not just within the heat transport and cooling systems, but also within the reactor vessel itself.

6. Power Cables

When it comes to high precision resistors, the nickel copper alloy with 45% nickel content is the one that is typically employed to make the resistance wires. In addition to that, you may use it as a thermocouple. The ratios of 90:10 and 70:30 produce allows that are more resistant to the effects of salt water.

7. Welding Consumables

When working in harsh conditions, nickel alloys are typically chosen because to the exceptional corrosion resistance or high-temperature qualities they possess.

Nickel alloys can also withstand high temperatures. Therefore, it is essential that the characteristics be preserved throughout the weld zone in order to ensure that the alloy will perform satisfactorily when it is put into service.

Nickel alloys have a high resistance to oxidation and corrosion, and when heated, they generate a layer of passivating oxide that is thick, stable, and protects them from further assault.

Nickel alloys have a high resistance to oxidation and corrosion. In addition, the strength of nickel alloys is not affected by a significant change in temperature. Because of this, they are especially desirable for use in applications that involve high temperatures.

FAQs: Nickel Alloys

Q How many Types of Nickel Alloys?

Ans. The most common types of nickel alloys are wrought nickel, nickel-iron alloys, nickel-copper alloys, nickel-molybdenum alloys, and nickel-chromium alloys.

Q. What is nickel alloy made of?

Ans. Compound steels with nickel as the main element are used to make nickel alloys.

Q. Is nickel a metal or an alloy?

Ans. There is only 25% nickel in the metal alloy that makes up a nickel.

Q. Is nickel alloy expensive?

Ans. Yes, Nickel alloys are generally expensive.

Q. How strong is nickel alloy?

Ans. Alloys made with nickel have Fe and Cr in them, are strong at high temperatures.

Related Topic:

Manufacturers & Suppliers of Nickel Alloy

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 23 Years |

Raghav Productivity Enhancers Ltd. Jaipur, India | 20 Years |

Steel Mart Mumbai, India | 19 Years |

Manhar Metal Supply Corporation Mumbai, India | 18 Years |

Govind Metal Co. Ahmedabad, India | 16 Years |

Nippen Tubes Mumbai, India | 9 Years |

Stainless Solutions Mumbai, India | 7 Years |

Ramani Steel House Mumbai, India | 7 Years |

Mitesh Tubes Mumbai, India | 7 Years |

Nandishwar Steel Mumbai, India | 6 Years |

Popular Products