Heavy Duty Activated Carbon Rotary Kiln

Price Trend: 250000.00 - 350000.00 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Weight (kg) | 120 Kilograms (kg) |

| Drive Type | Electric |

| Supply Ability | 1 Per Month |

| Delivery Time | 50 Days |

Product Overview

Key Features

---Stable with high Iodine and MB value quality AC

---Automatic operation.

---Easy maintenance

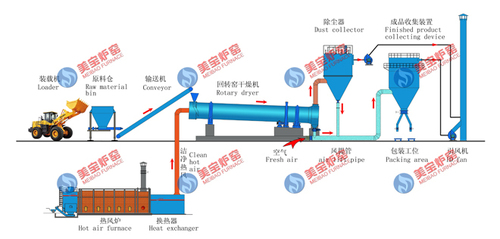

Xingyuan Activated Carbon Steam Activation A A Rotary Kiln

Steam activation is the most widely used process because it is generally used to activate both coconut shell and coal based carbons. Steam activated carbons are produced in a two-stage process. Firstly the raw material, in the form of lumps, pre sized material, briquettes or extrudates, is carbonized by heating in an inert atmosphere such as flue gas, so that dehydration and devolatilization of the carbon occur. For this stage temperatures usually do not exceed 700 C. Carbonization reduces the volatile content of the source material to under 20%. A coke is produced which has pores that are either small or too restricted to be used as an adsorbent.

The second stage is the activation stage which enlarges the pore structure, increases the internal surface area and makes it more accessible. The carbonized product is activated with steam at a temperature between 900C and 1100C. The chemical reaction between the carbon and steam takes place at the internal surface of the carbon, removing carbon from the pore walls and thereby enlarging the pores. The steam activation process allows the pore size to be readily altered and carbons can be produced to suit specific end-sues. For an example, the pore structure has to be opened up more for the adsorption of small molecules from a solution, as in water purification, than for the adsorption of large colour molecules in sugar decolorization.

Steam Activation produce activated carbon in the from of 1mm to 3mm pieces, which are crushed and screened to remove fines and dust to meet the specifications for granular activated carbons. To produce powdered activated carbons, the carbon pieces are further ground using a gentle pulverizing action.

We are making, supply, exporting and trading huge range of Activated Carbon Making Machines in Xinji, Hebei, China. Our offered range of Activated Carbon Machine is available with following specifications :-

1) Rotary kiln for activated carbon

2) with S.S surface and fire bricks inside

3) around 120 tons

4) size:18-32meter longth ,diameter 1.8-2.5meter

5) daily capacity 1-3tons

Product Feature

1.Yearly Capacity 1000MT Shell Based AC

2.CAPACITY:

DAILY CAPACITY 3TONS.

3.CHANGE RATE:

COCONUT SHELL :AC=4.5-5:1

4.CONSUMPTION :

DAILY CONSUMPTION RAW COCONUT SHELL 15MT, DAILY ELECTRICITY CONSUMPTION 100-200KWH , DAILY WATER CONSUMPTION 5-10MT ,

Application:-

to produce the shell based and wood based activated carbon, granular activated carbon and powder activated carbon.

Company Details

Focusing on a customer-centric approach, Xinji Xingyuan Machinery Co. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cement Plant Machinery in bulk from Xinji Xingyuan Machinery Co. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Importer, Manufacturer

Employee Count

50

Establishment

1998

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Xinji, Hebei

Import&export Manager

Mr Richi Yao

Address

Xingyuan Group Building, Nanlvcun Industry Zone, Xinji, Hebei, 052360, China

rotary kiln in Xinji

Report incorrect details