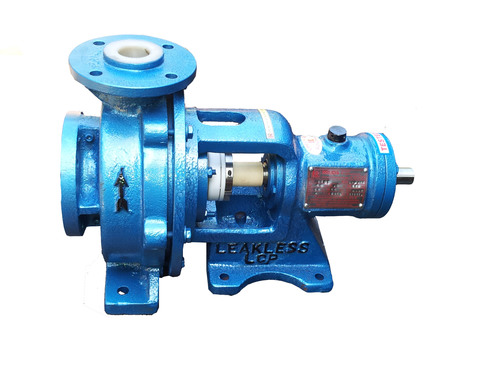

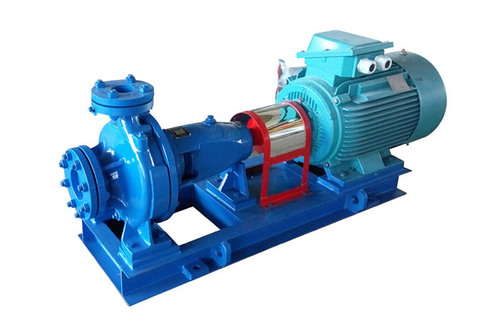

Advanced Ceramic Acid Pump - Sic Ceramic + Metal | High Flow Rate 200-10000 M3/h, Single Stage Centrifugal, Mechanical Seal, High Pressure

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Head Size | 20-45 mm |

| Inlet/Outlet | 100-1100 mm |

| Flow Rate | 200-10000 m3/h |

| Theory | Centrifugal Pump |

| Material | Sic Ceramic + Metal |

| Structure | Single Stage Pump |

| Power | Electric |

| Standard | Chinese Standard |

| Fuel Type | Electric |

| Pressure | High Pressure |

| Usage | Water, Paper Printer |

| Application | Other |

| Suction Type | Single Suction |

| Seals Type | Mechanical Seal |

| FOB Port | Dalian, Tianjin, Shanghai |

| Payment Terms | Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 5000 sets Per Month |

| Delivery Time | 7- 30 after receiving the advance payment Days |

| Packaging Details | Standard Export Packaging |

| Main Export Market(s) | Eastern Europe, Middle East, Africa, Asia, North America |

| Main Domestic Market | All India |

| Certifications | ISO 9001 |

Product Overview

Key Features

Advanced Ceramic Acid Pumps is a large-flow, low-lift, cantilever single-stage centrifugal pump. Particularly suitable for conveying highly abrasive and corrosive media. Its core technology is based on the metal efficient hydraulic model, using CFD design means, using the solid-liquid two-phase flow hydraulic design method, unique "ceramic + metal" composite manufacturing process.

Ceramic material:

Ceramic materials are professional and reliable. According to the characteristics of the conveying slurry, a ceramic material with high strength, wear resistance and corrosion resistance was developed. The unique injection molding technology was used to ensure the reliability of the combination of ceramic materials and metal components. The abrasion resistance test of the comparative material of the Institute of Casting and Wear-resistant Materials of Xi'an Jiaotong University shows that the wear resistance of silicon carbide ceramic material is 3.5 times higher than that of high chromium alloy (Cr30).

2.2 Ceramic pump lining:

With optimized design and special manufacturing processing technology, silicon carbide ceramics are used for the pump housing and the pump cover lining. The external use of metal armor makes the pump highly reliable, safe, and easy to disassemble and install. The special ingredients and technology of ceramic materials ensure that the metal shell and the ceramic lining are integrated and tightly combined.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

168

Establishment

1962

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Shenyang, Liaoning

Overseas Department Minister

Ms Lydia Han

Address

No 17, Road-23, Shenyang Economic & Technological Development Zone, Shenyang, Liaoning, 110176, China

acid pumps in Shenyang

Report incorrect details