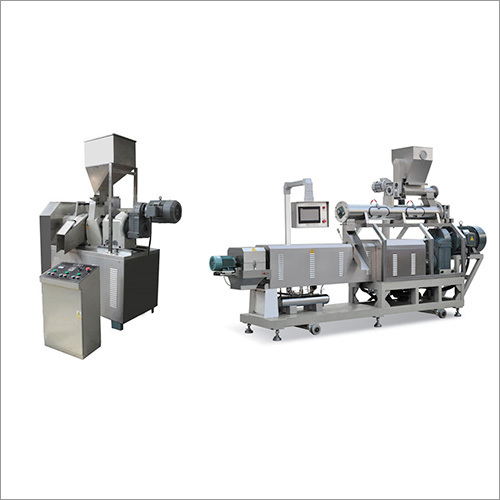

Automatic Cheetos Kurkure Plant Processing Line - Stainless Steel, 20x2x3 M, 100-150 Kg/h Capacity | Eco-friendly, High Efficiency, Low Noise, Lower Energy Consumption

Price Trend: 6000.00 - 30000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | machinery |

| General Use | used for making kurkure |

| Material | Stainless Steel |

| Capacity | 100-150kg/h Kilogram(Kg) |

| Weight (kg) | 500 Kilograms (kg) |

| Product Shape | Other |

| Computerized | No |

| Automatic | Yes |

| Control System | Manual |

| Installation Type | Free Stand |

| Voltage | 220V/380V/415V/440V Watt (w) |

| Power | 90kw, 120kw, 130kw Watt (w) |

| Dimension(L*W*H) | 20*2*3 Meter (m) |

| Raw Material | Corn |

| Feature | Low Noice, High Efficiency, Lower Energy Consumption, ECO Friendly, Compact Structure |

| Color | Other |

| Warranty | 12 months |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 30sets Per Month |

| Delivery Time | 30 days after receiving your deposit Days |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Wooden cases for necessary machines |

| Main Export Market(s) | Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia |

| Main Domestic Market | All India |

| Certifications | CE,ISO,SGS |

Product Overview

Key Features

Raw materials

Corn grits

Production capacity:100-150kg/h

Voltage and frequency

Three phases: 380V/50Hz, Single phase: 220V/50Hz (China standard)

We can make it according to customers' Local voltage according to different countries (440v/ 415v /440V etc).

Fried kurkure cheetos production line

1. Mixer- 2. screw conveyor- 3. extruder-4. hoister-5.separator- 6. vibrating feeder-7. fryer- 8.vibrator- 9.flavoring system(Oil sprayer, hoister and flavoring roller)

Roasted kurkure cheetos production line

1.Mixer-2.screw conveyor- 3. extruder-4. air conveyor-5. roasting oven- 6.flavoring system(Oil sprayer, hoister and flavoring roller)

Packaging and shipping

A. We will pack all necessary machines into wooden cases. For drying machine, and heavy extruders, we will fix them in the container with very strong iron wire.

B. If by LCL for small quantity machines, we will let send to QINGDAO port for loading.

C. If need containers, our trucks will take the containers from port to our factory for professional and safely loading, and then return to port for shipment.

Service

1. Consultation service before, during,and after sales;

2. Project planning and design service;

3. Debugging of equipment until everything is functional;

4. Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5. Training of equipment maintenance and operating personally;

6. New production techniques and formulas;

7. Provide 1 year complete warranty and life-time maintenance service

Factory

1. 9 years manufacturing experience

2. Exporting to many countries, rich exporting experience

3. Approved by CE,ISO,SGS

4. Professional sales and after sales team, engineer available to serve overseas

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

51

Establishment

2009

Working Days

Monday To Sunday

Certification

ISO9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinan, Shandong

Ms. Jasmyn Cao

Address

No. 18, 3rd Area, Xiaoluzhuang Industrial Park, Tianqiao, Jinan, Shandong, 250032, China

kurkure machine in Jinan

Report incorrect details