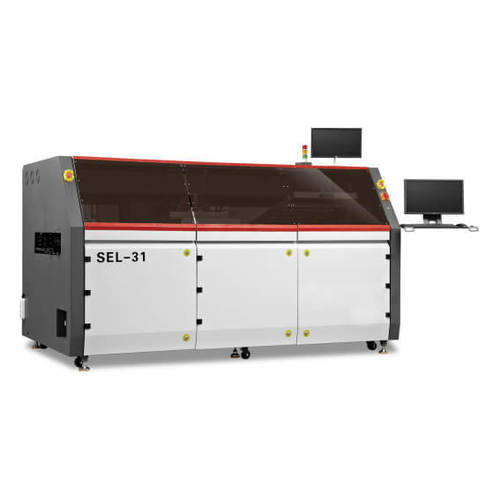

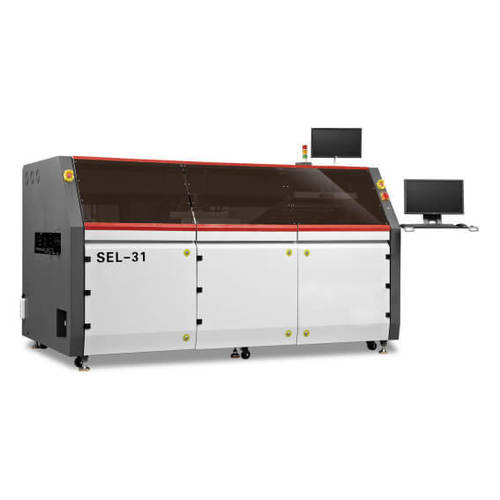

Automatic Selective Soldering Machine

Price:

Get Latest Price

In Stock

Product Overview

Key Features

(1) Double head spray and welding, greatly improve production efficiency.

(2) PCB plate fixed, spray and welding platform moving.

(3) High welding quality, greatly improve the pass rate of welding.

(4) Modular design of SMEMA online transportation, support customers for flexible line formation.

(5) Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

Standard machine include:

Serial : 1

Item : Controlling system

content : PC & monitor

Quantity : 1 set

Live on monitor camera

motion control

Serial : 2

Item : Platform motion system (Flux Sprayi

Content : XY motion table

Quantity : 1 set

2 axis equipped with ball screw & linear guild rail

2 axis equipped with servo motor & driver

Serial : 3

Item : Fluxing system

Content : Imported fluxing jetting valve

Quantity : 1 set

flux tank

flux pneumatic system

Nozzle automatic cleaning system

Serial : 4

Item : Preheating system

Content : Preheat the hot air,IR heater at bottom

Quantity : 1 set

Serial : 5

Item : Platform motion system (Solder poti

Content : xyz motion table

Quantity : 1 set

3 axis equipped with ball screw & linear guild rail

3 axis equipped with servo motor & driver

Serial : 6

Item : Soldering pot

Content : 15kg capacity solder pot, impeller, tunnel, servor motor

Quantity : 2 set

solder temperature over heat alarm system

solder temperature controlling system

n2 inline heating system

Standard equipped solder nozzlei inner 4mm x 3pcs, 5mm,6mm )

Serial : 7

Item : Conveyor system

Content : Independent step drive of front and rear transport guide rail (spray preheating section)

Quantity : 1 set

Front and rear chain transportation guide (spray preheating section)

Spray section of PCB plate blocking device, preheating section

Independent step drive of front and rear transport guide rail (tin soldering section)

Front and rear roller transport guide (tin soldering section)

PCB plate blocking device tin soldering section

side clamping system

Serial : 8

Item : Machine chassis

Content : Machine frame/cover & painting

Quantity : 1 set

1.Short lead time;

2.Quality guaranteed.

3.All size and model available.

Flason SMT are long term and stable supplier of above stated SMT parts.

Flason SMT will Provide high quality and low price goods and perfect follow-up service.

Keywords:

smt wave soldering machine,smt soldering oven, THT soldering machine, SMT soldering machine, smt assembly linedual wave soldering machine, PCB soldering machine, SMT assembly machine, PCB soldering dual wave machine, LED wave soldering machine, LED PCB wave soldering machine.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

65

Establishment

2009

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shenzhen, Guangdong

Mr Tommy Wu

Address

Flason Industry Park Shajing Town, Baoan District Shenzhen, Shenzhen, Guangdong, 518129, China

wave soldering machine in Shenzhen

Report incorrect details