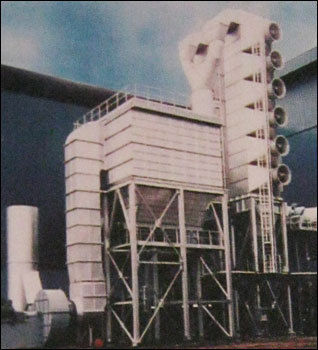

Bag Filter - High-efficiency Cyclone Separator , 95%-98% Dust Collection With No Moving Parts

Price:

Get Latest Price

In Stock

Product Overview

Key Features

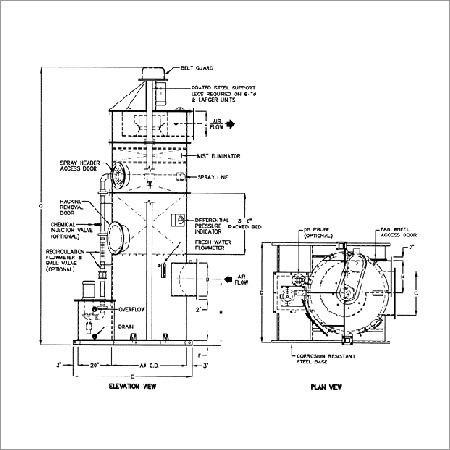

Cyclone Separators are normally used for the collection of the coarse

dust particles. In a cyclone separator, dusty air is introduced at the

top of a cyclone through the inlet pipe located tangentially to the

cylindrical portion. The gases then move downwards in a whirling

motion, forming a peripheral vortex and giving rise to centrifugal

forces, resulting in a throwing of the dust particles towards the

walls, which then move downwards into the hopper and are removed

through the draw-off pipe.

The gases, after reaching the end of the conical portion, change

direction and move upwards towards the outlet, forming an inner vortex.

In this upward movement of gases against gravity, more dust particles

are separated and fall into a conical hopper for subsequent removal.Advantages

Stable pressure drop for a given gas flow

Constant efficiency for a given particulate condition

No moving parts; no replaceable filters

Ability to handle extremely high dust concentration

High temperature capability

Efficiency

On Industrial Coarse Particulate FD Cyclones are 95% to 98% efficient.

Efficiency is a function of the physical parameters of the application

and the design parameters of the cyclone. Cyclone efficiency increases

with:

Coarse particle size distribution

Higher product specific gravity

Lower gas density

A decrease in cyclone diameter (two smaller cyclones in parallel will

have a higher efficiency than one larger cyclone with an equal pressure

drop)

Smaller outlet diameter. An increase in pressure drop also results.

Efficiency and pressure drop are also affected by barrel length, outlet

length, inlet configuration, and design of the internal cone. These

factors are optimized to result in the maximum possible efficiency at a

practical overall size and pressure drop.

Company Details

Focusing on a customer-centric approach, Concept Engineering System has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pollution Control & Monitoring Equipment in bulk from Concept Engineering System at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1997

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Nalasopara, Maharashtra

Proprietor

Mr. S. Suvarna

Address

S/2, Chandresh Plaza, Cross Achole Road, Sayukta Nagar, Nalasopara (E), Taluka Vasai, Distt. Thane, Nalasopara, Maharashtra, 401209, India

Report incorrect details