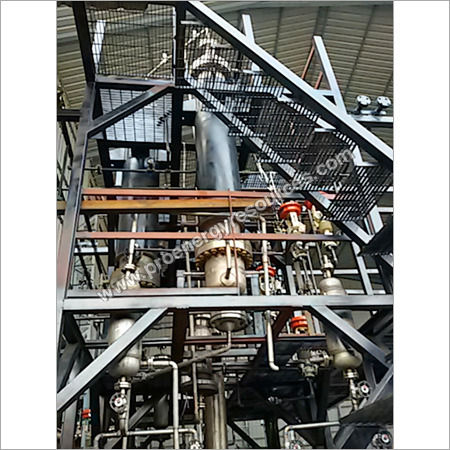

Biogas Plant Biogas can be produced by fermentation of biodegradable material such as green waste, plant material, sewage, manure, municipal waste or by anaerobic digestion with anaerobic bacteria. Our biogas plants offer maximum efficiency, added value and high flexibility for a range of applications. They provide a variety of ecological & economic benefits. The plants contribute to value creation in rural areas by utilizing renewable raw material and agricultural products. Specification:BIOGAS PROCESS : Commonly known as raw spent wash, distillery effluent is one of the most polluting effluents with very high values of COD, BOD, dissolved solids and suspended solids. This dark-brown effluent has high potential of biogas generation, which can be used as fuel. Also, it can be burnt directly in boiler, and can be utilized to generate electricity by burning it in biogas engines. Process of anaerobic digestion is used to convert this high-strength waste water into biogas. Based on CSTR process, the Digester offered by ProEnergy provides higher efficiency of treatment and is known as the best available amongst anaerobic processes. The CSTR system offers higher and consistent biogas production. It is the most reliable as well as easy to operate system. TREATMENT STRATEGY : Offered by ProEnergy, the CSTR process is based on the concept of organic matter conversion into biogas. The conversion process of organic matter into biogas performs through a group of bacteria. In the high rate CSTR process, anaerobic digestion takes place in the mesophillic range of temperature, i.e. 36 to 40C. The pH in the reactor is kept around 7.2, while proper volatile acid and alkalinity ratio is maintained. The process of anaerobic digestion, covers the following three stages:Hydrolysis: In the hydrolysis process the complex molecular compounds i.e. Polymers are changed into simple molecular form i.e. Monomers. Acidogenesis: At the end of hydrolysis process the monomers are formed that are converted into volatile fatty acids. The major portion of volatile fatty acids is formed by Acetic acid. The conversion process of monomers into acids is performed by a group of anaerobic bacteria known as acid formers. Methanogenesis: At the end of Acidogenesis process the Acids are produced, and are converted into methane and carbon dioxide gases. The conversion process of acid into gases is done by a group of anaerobic bacteria known as the methane formers. In CSTR process the bacteria responsible for the process of digestion are kept in suspension through lateral and central Agitators. CSTR REACTOR : The CSTR Reactor is designed on the anaerobic contact process principle. In a central shaft, raw effluent enters the CSTR at the top. Also, the Recirculated sludge is blend with raw effluent in a central shaft. To facilitate mixing as well as downward movement of the mixed effluent, a central agitator is provided at the top. The effluent moves to the bottom of reactor via central shaft. In the reactor, the effluent contacts with active anaerobic culture, managed in the suspension. In this process the effluent's organic matter is converted into cell mass and biogas. Liquid travels upward in the reactor. For mixing & upward movement of the liquid, the lateral agitators are provided. BIOGAS RECOVERY: Biogas can be collected at the top of the reactor, and stored in a gas-holder which is separately constructed. Fabricated in MS plated, the Biogas holder is of floating type. Biogas from biogas holder can be compressed and then sent to the boiler for burning. In order to flare the excess biogas the flare stack is provided.