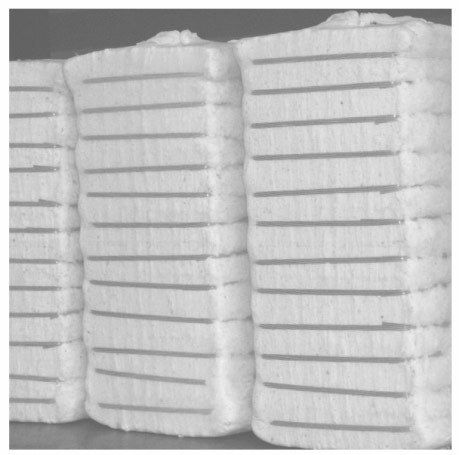

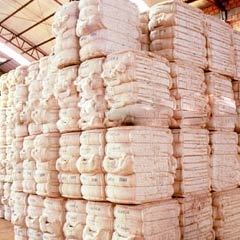

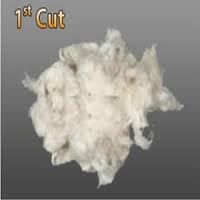

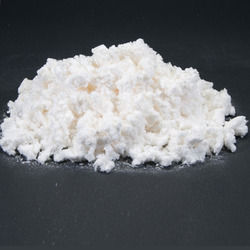

We can supply the best quality 100% Natural Cotton Linter to you. Our price is competitive and we assured of good cotton linters which can match your required specifications, and standards. and, can take responsibility to any quality uncertainty. Presently, we are looking forward to more cooperation with overseas based on mutual profit. Our items comply with International Quality Standards and their quality and durability are fully guaranteed. Our factory can provide the most preferential profit to customers all over the world with competitive prices and high quality items.We can supply cotton seeds cotton linters-CSCL- From India, and from Pakistan. From India Original-Genuine cotton linters are available, We can supply original cotton linters-from India 500 Mts. to 1500 Mts. per Every Months. From Indias biggest cotton linters manufacturing plant, 300 to 400 Mts. cotton seeds we process In delinting machines, to produce 30 Mts.cotton linters 1st. cut + 2nd. cut Per day, World best cotton linters 1st. cut + 2nd. cut, from India.1st Cut MediumWe can export our 100% Natural Cotton Linter to Russia, Syria, New Zealand, Brazil, China, Ukraine, etc. 1st. cut cotton linters are always in best quality, Bcos both cotton linters products, 1st. cut and 2nd. cut produced from entirely different ways.1st. cut produced from Cotton Ginning Industries, in process of raw cotton in super cleaners, prior to press the bales. And, 1st. cut cotton linters staples length is 5 to 10 mm. maximum. 2nd. cut produced from Cotton Seeds Expelling Industries, and from Solvent or Oil Extractions plant in the process in Delinted Machines., Lints removed from Cotton Seeds, 2nd. cut cotton linters produced,the staples length are 2 mm. to 5mm. maximum.3rd. cut cotton linters are little low grade varieties of 1st. cut cotton linters.2nd Cut MediumFibre Types:Cotton Gossypium species (various, depends where grown) Cotton Linters Short, coarse fibres which adheres to the cotton boll, after removal of the very long textile fibres. There are broadly three classes: Mill Run (Longest fibre), First cut(Long fibre) and Second cut (Shorter fibre)Fibre Properties : Fibre Length mm Millrun/First cut 1.6-2.0; Second cut 1.0-1.4, Fibre Coarseness ?g/m Mill run /First cut 230-260; Second cut 200-250Bauer McNett 14 mesh Screen Retention % Mill run/First cut 35-50; Second cut 1-20DESCRIPTIONS OF COTTON LINTERS:1st-cut produced from Cotton Ginning Industries, in process of raw cotton in super cleaners, prior to press the bales. And, 1st. cut cotton linters staples length is 5 to 10 mm. maximum.2nd-cut produced from Cotton Seeds Expelling Industries, and from Solvent or Oil Extractions plant in the process in Delinted Machines., Lints removed from Cotton Seeds, 2nd. cut cotton linters produced, the staples length are 2 mm. to 5mm. maximum.3rd. cut cotton linters are little low-grade varieties of 1st. cut cotton linters, Fibre Types : Cotton Gossypium species (various, depends where grown) Cotton Linters Short, coarse fibres which adheres to the cotton boll, after removal of the very long textile fibres. There are broadly three classes: Mill Run (Longest fibre), First cut(Long fibre) and Second cut (Shorter fibre) Fibre Properties : Fibre Length mm Millrun/First cut 1.6- 2.0; Second cut 1.0A composition of a loose mass of comminuted raw cotton linter fibers has a bulk density of at least 8 g/100 ml and at least 50 % of the fibers in the mass passes through a US standard sieve size #10 (2 mm opening). This composition is made by obtaining a loose mass of first cut, second cut, third cut, or mill runs raw cotton linters or mixtures thereof and comminuting the loose mass of raw cotton linters to a size wherein at least 50 % pass through a US standard sieve size #10 (2 mm opening). This composition is used to make cellulose ether derivatives.Eco-friendly Cotton Seed Delinting Plant :-It is design & development and testing of a pollution-free cotton seed delinting plant. The capacity of the indigenous cotton seed delinting plant is 1.0 TPH tonnes/hr. The plant is based on dry HCL gas generation without the use of sulphuric acid and has been installed at India, The new eco-friendly technology has been dully certified by the Pollution Control Board. The machines have been coated with taflan and lined with FRP for corrosion resistance. Electric power consumption has been minimized and the initial cost of installation is considerably lower than other imported and indigenous plants. The cotton linters after the delinting process are converted into a powder which could be further refined to pharmaceutical grade cellulose. Thus, the process of obtaining clean cotton seed after delinting has been made completely eco-ftiendly without any adverse environmental effect. The technology is available for commercialization.