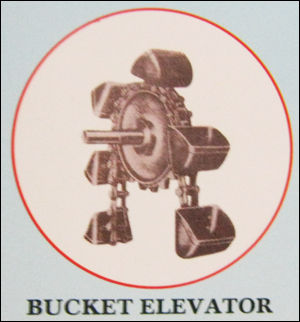

Chain Type Bucket Elevators

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Being a customer-focused organization, we are engaged in offering Chain Type Bucket Elevators as per the market demand. These are widely applied in various industries such as chemical, metallurgy, plastic and building industries. All the elevators offered by us are manufactured by our skilled workers using excellent quality stainless steel. Furthermore, these Chain Type Bucket Elevators consist of adjustable discharge plate, and braced bearing mountings for its proper functioning. Other details: The bucket elevator casings are self supporting, but they require horizontal guides at least every 15 meters and below the elevator head. The bucket elevator head comprises a lower section with doors to access the adjustable discharge plate, and braced bearing mountings, for the pedestal bearings which support the drive shaft, the shaft exit points use grease filled radial shaft seals. The upper sections comprise a multipart removable hood with an inspection flap. A drive platform is mounted on the side of the lower part of the head for supporting a wide variety of commercially available drives. If required a maintenance platform and or an overhead support/ service beam can be fitted if required. An elevator drive normally consists of a geared motor unit, which is normally connected to a frequency controller for maintenance purposes. For higher power requirements, we recommend a drive unit with a bevel spur gearbox, and standard motor optionally with auxiliary drive. Starting characteristics can be optimized by a hydraulic clutch or an electric soft start. The double or single leg casing is torsionally rigid sheet metal housing, constructed of standard section lengths with flange connectors. The maintenance and assembly door position should preferably be located in the elevators raising casing leg, approximately 0.8 m above a platform. The elevator boot is optionally designed with either internal, oil-filled bearings or external pedestal bearings. With external bearings, the shaft exit points are sealed by gray cast-iron stuffing boxes. There are large assembly doors and cleaning doors on both sides. The chain takeup tension is generated by a weight or spring-loaded spindle take-up device. Depending on the type of chain used, RUD driving wheels are either non-toothed chain pulleys with replaceable, highly wear-resistant segments, or toothed sprocket wheels with replaceable, highly wear-resistant teeth. The RUD return wheels have replaceable, highly wear-resistant segments which in certain designs incorporate guide discs. Buckets are manufactured according to DIN or our works standard. The materials used are steel, stainless steel, or rubber. Buckets are attached by chain shakkles, bolted clamping clips, plug-in attachments or angle brackets. The chains are either hardened, round link chains to DIN Standard or works standard chain designs made of special, highly wear-resistant alloy steel. Engineering style chains are also used, as either double or single central chains. Standard safety devices such as speed governors and level indicators, to monitor the operating status of the bucket elevator are incorporated. Additional accessories are available.

Company Details

Focusing on a customer-centric approach, Rud India Chain Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Bucket Elevator in bulk from Rud India Chain Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

1000

Establishment

1900

Working Days

Monday To Sunday

GST NO

27AADCR7979M1ZF

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AADCR7979M1ZF

Thane, Maharashtra

Mrs. Kamala

Address

111/112, 1st Floe, Orion Business Park, Next To Cine Wonder Mall, Ghodbunder Road, Thane West, Thane, Maharashtra, 400607, India

elevators in Thane

Report incorrect details