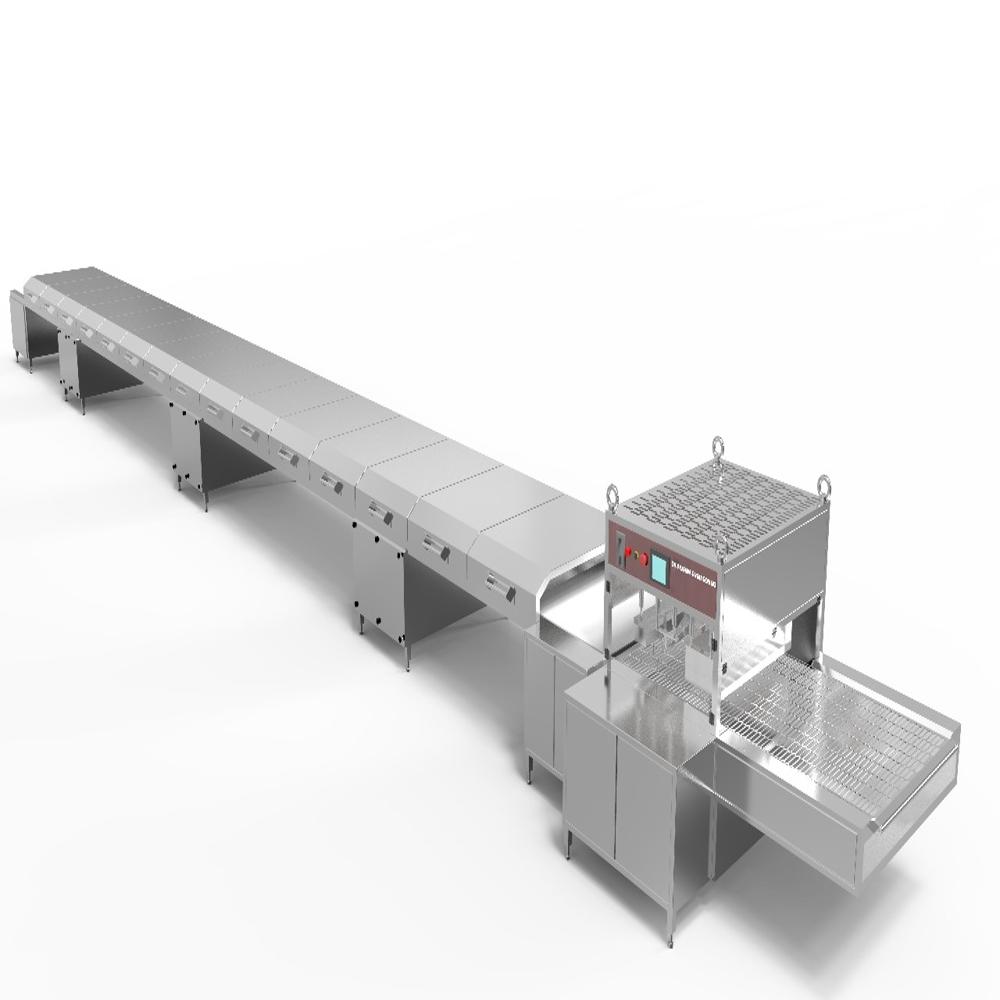

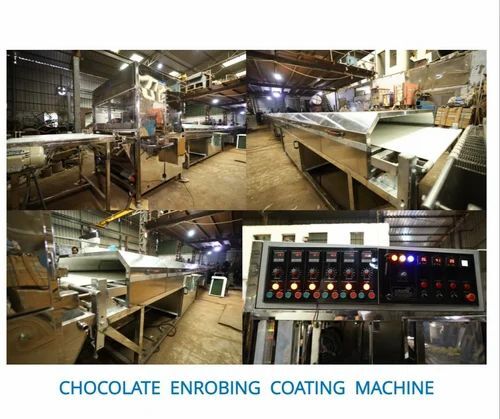

Chocolate Enrobing Machine By Dolce Engineering

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Chocolate Enrobing Machine |

| General Use | Chocolate Enrobing |

| Material | Stainless Steel |

| Computerized | No |

| Automatic | Yes |

| Control System | PLC Control |

| Voltage | 220/380 Volt (v) |

| Color | Silver |

| Payment Terms | Telegraphic Transfer (T/T) |

| Delivery Time | 1 Week |

| Packaging Details | Industry Standard |

| Main Domestic Market | All India |

Product Overview

Key Features

1. **Conveyor System:**

- **Mesh Conveyor Belt:** Enrobing machines typically have a mesh conveyor belt that carries the food items through the chocolate curtain.

- **Variable Speed Control:** The conveyor speed is adjustable to accommodate different production rates and chocolate flow characteristics.

2. **Chocolate Curtain System:**

- **Chocolate Reservoir:** The machine has a reservoir that holds a significant amount of melted chocolate.

- **Enrobing Curtain:** The melted chocolate is continuously circulated over the conveyor belt, creating a curtain through which the food items pass.

3. **Wire or Blade System:**

- **Wire or Blade Cutter:** As the coated products move along the conveyor, excess chocolate is removed using a wire or blade system. This ensures a uniform coating thickness.

4. **Cooling Tunnel Integration:**

- **Cooling Tunnel Attachment:** Enrobed products often pass through a cooling tunnel immediately after the enrobing process to set and harden the chocolate coating.

- **Controlled Cooling:** The cooling system is designed to achieve controlled cooling for proper crystallization of the chocolate.

5. **Compatibility:**

- **Versatility:** Enrobing machines are versatile and can be used for coating various food items, such as biscuits, cookies, nuts, fruits, and more.

- **Adjustable Coating Thickness:** Some machines allow for the adjustment of the chocolate coating thickness to meet specific product requirements.

6. **Cleaning and Maintenance:**

- **Easy Cleaning:** The machine is designed with easy-to-clean parts, and some components may be removable for maintenance.

- **Hygiene Standards:** Like other chocolate processing equipment, enrobing machines are designed to meet hygiene standards in food manufacturing.

7. **Heating and Temperature Control:**

- **Heating Elements:** Enrobing machines have a heating system to maintain the chocolate at the desired temperature for consistent coating.

- **Temperature Control:** Precise temperature control is important for ensuring proper chocolate flow and coating adhesion.

8. **Adjustable Nozzles:**

- **Nozzle Adjustability:** Some machines have adjustable nozzles to control the flow of chocolate, especially for products with intricate shapes.

Chocolate enrobing machines are commonly used in large-scale chocolate production facilities where efficiency, consistency, and precision in coating are crucial. The automation provided by these machines streamlines the enrobing process, making it faster and more cost-effective compared to manual methods.

Company Details

Business Type

Manufacturer, Distributor, Supplier, Trading Company

Employee Count

10

Establishment

2018

Working Days

Monday To Sunday

GST NO

36AEVPU5533P1ZC

Related Products

Explore Related Categories

Seller Details

GST - 36AEVPU5533P1ZC

Hyderabad, Telangana

Proprietor

Mr Upendar

Members since

3 Years

Address

12-2/488/A/1, Plot No.488 & 489, Survey No.277 to 285, Sree Nagar Colony,Nagaram Municipality, Rampally (V), Keesara (M), Hyderabad, Medchal-Malkajgiri Dist. Hyderabad, Telangana, 501301, India

chocolate enrobing machine in Hyderabad

Report incorrect details