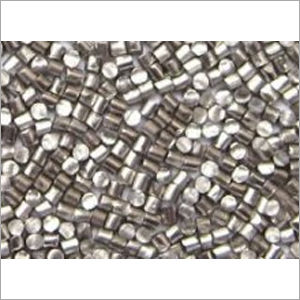

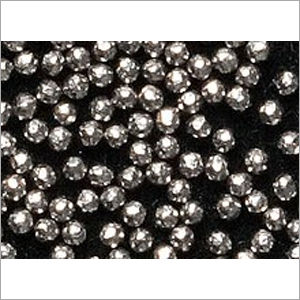

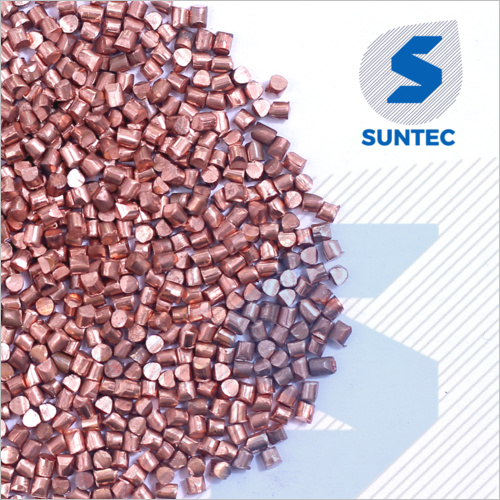

Due to our perfection and customer-centric approach, we have marked a distinct position in this domain as the distinguished manufacturer and supplier of Copper Cut Wire Shots. The provided cut wire shots are manufactured using quality-assured copper wires and sophisticated techniques in tune with industry standards. Suitable for surface treatment applications, the offered cut wore shots is compatible for descaling, burr removing, etching, finishing, leveling, surface stress relief and other allied applications. Also, these cut wire shots are stringently tested on set qualitative parameters to assure their flawlessness. Additionally, we offer these Copper Cut Wire Shots to the clients in various densities, finishes and sizes at an affordable price range. Features: Heat treated and cold drawn to achieve hardness and homogeneity Lower consumption for economical peening applications Consistent finishing and cleaning Uniform size, density and hardness ADVANTAGES OF COPPER CUT WIRE SHOT Cost effective and low consumption Consistency in shape, size and hardness Cleans the product faster Available in varied size as per requirement It increases the fatigue life of blasted components Longer life till reduced to smallest particles There is no possibility of dust formation during shot blasting Helps in cutting down maintenance cost of the shot blasting machine Assurance of no dust/ health hazard during operations Details:These cut wire shots find application in various industries for shot blasting, shot peening and processes to remove paints. Moreover, these are available in maximum diameter of 2.4mm. The cut wire shots are designed in various degrees of conditioning such as normal conditioning that meets the shape requirements of SAE J441 Specifications. Rounded special conditioning fulfils the requirements of Aerospace specifications such as AMS 2431.