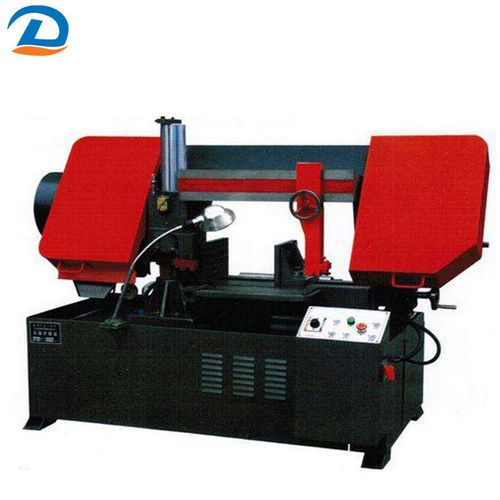

Double Column Sawing Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | Variable |

| Blade Size | Variable |

| Cutting Capacity | Variable |

| Weight | Variable |

| Hydraulic System | Closed-Loop |

| Features | Hydraulic Control, Stepless Speed, Double Column, Stable Sawing, High Precision, Easy Operation |

| Product Type | Double Column Sawing Machine |

| Payment Terms | Telegraphic Transfer (T/T), Paypal, Others, Letter of Credit (L/C), Western Union |

| Delivery Time | 1 Months |

| Main Domestic Market | All India |

Product Overview

Key Features

The main components of the double-column horizontal metal band sawing machine are: bottom seat; A bed and a column; Saw beam and transmission mechanism; Guide device; Workpiece clamping; Tensioning device; Feeding; Hydraulic transmission system; Electrical control system; Lubrication and cooling system.

The hydraulic transmission system consists of a hydraulic loop composed of pumps, valves, oil cylinders, oil tanks, pipelines and other auxiliary parts. Under the electrical control, the lifting of the saw beam and the clamping of the workpiece are completed. Through the speed regulating valve can be implemented in the feed speed stepless, to achieve the sawing of different materials workpiece needs.

The electrical control system is composed of electrical box, control box, junction box, travel switch, electromagnet, etc., which is used to control the rotation of the saw blade, the lifting of the saw beam, the clamping of the workpiece, etc., so as to realize the normal cutting cycle according to a certain working procedure.

Lubrication system must be lubricated according to the requirements of the lubrication parts of the machine (wire brush shaft, worm box, active bearing, worm bearing, up and down shaft of lifting cylinder, clamping screw rod on the sliding surface of the movable vice) before starting up. The worm gear and worm gear in the worm gear box are lubricated by no. 30 oil bath, which is injected by the oil plug hole in the upper part of the worm gear box. The oil mark is provided on the head of the box. After trial for one month, oil should be changed. After that, oil should be changed every 3-6 months. The lower part of the worm gear box is equipped with oil drain plug.

main feature:

Cutting speed hydraulic control, stepless speed regulation;

Guide block structure scientific and reasonable, prolong the service life of saw blade;

Double column structure, stable operation;

Stable sawing, high precision;

The work clamping adopts hydraulic clamping, easy to operate.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Producer

Employee Count

50

Establishment

2011

Working Days

Monday To Sunday

Payment Mode

Letter of Credit at Sight (Sight L/C)

Certification

ISO 9001:2008

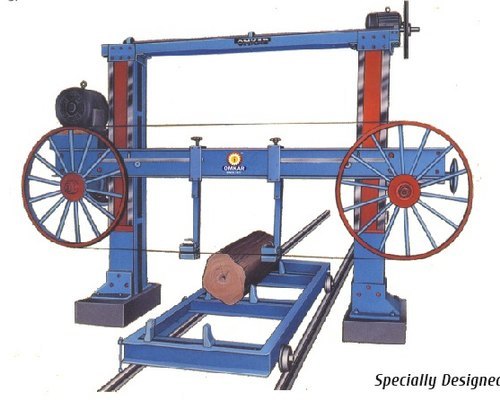

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Mrs Lemon

Address

905 of One World Business Center, Cangzhou, Hebei, 061000, China

horizontal band saw machine in Cangzhou

Report incorrect details