Double Head Pipe End Forming Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Max Capacity | 40 2Mm |

| Max Stroke | 100Mm |

| Forming Speed | 100/3-4 Mm/Sec |

| Working Pressure | 12 Mpa |

| Motor Power | 4 Kw |

| Material | Steel |

| Control | Hydraulic/Electric |

| Features | High Efficiency, Automatic Operation, Double Head, Easy Operation, High Accuracy, Cost Effective, Durable Parts, Emergency Stop, Water Cooling, Multiple Materials |

| FOB Port | Shanghai |

| Supply Ability | 50-80 Per Month |

| Delivery Time | 15-60 Days |

| Packaging Details | wooden packing |

| Main Export Market(s) | Australia, South America, Middle East, Western Europe, Africa, Central America, Eastern Europe, Asia, North America |

| Certifications | CE |

Product Overview

Key Features

Pipe End Forming Machine

Model: DTM-40

Max. End Forming Capacity: A Ac40A A 2mm

Max. End Forming Stroke: 100mm

End Forming Speed: 100/3-4 mm/sec

Max. Working Pressure: 12 Mpa

Motor Power: 4 Kw

SLS Double Head Pipe end forming machine is a kind of high efficiency,automatic machine. It can be do different types of end forming as reduction, expansion, beads, flare and thickening.Each of these categories has special requirements and is used in a variety It is controlled by hydraulic and electricity at the same time.It works double head on forming time.It combines easy-to-use operation with high end forming accuracy and cost effectiveness.

STANDARD

Human Interface offers easy access to auto and manual operating modes.

All the parts are made under very strict quality control, so the quality of machine is

In high level and the specification is standardized.

Equipped with emergency stop device. Both manual and automatic operations are available.

Tube clamping and end forming driven by hydraulic.

Available pipe material: steel, stainless, aluminum, titanium and brass...

The design of the tooling help customer easy to change.

Water cooling system ensures the equipment long-time work stably under the high temperature.

CE&ISO 9001:2000

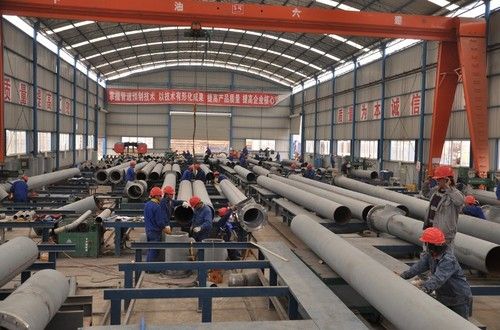

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier

Establishment

2016

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhangjiagang, Jiangsu

Ms Julia Xu

Address

Economic Zone, Zhangjiagang, Jiangsu, 215600, China

pipe making machines in Zhangjiagang

Report incorrect details