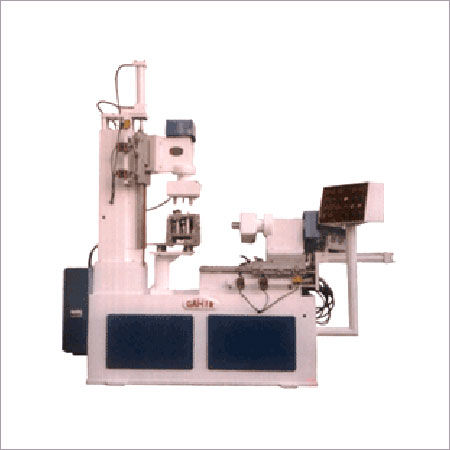

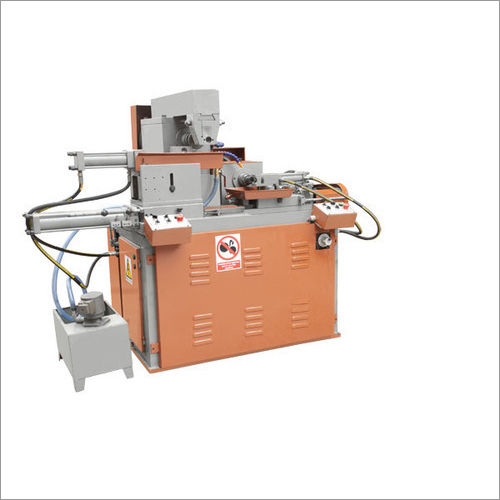

With the help of our experts, we have been instrumental in offering our clients an excellent quality assortment of Dual Spindle Machine that is widely used in graphite block manufacturing industry and automobile industry. Offered machine is manufactured at per industrial norms by our adept professionals using premium quality basic raw material and sophisticated technology. Also, this machine is rigorously tested by our quality inspectors before delivering to clients. To meet the varied demands of our esteemed clients, we are offering this Dual Spindle Machine in various technical specifications at most reasonable prices. Features: High operational fluency Low maintenance Energy efficient Longevity Main components Casted iron (25 grade) 6 piece: base, column, spindle box, lift platform, panel, worktable All the spindle bearing come form Nsk Japan Electrical system: Power contactor, Mcb 32A, electrical board bakelite sheet, Safety fuse with base with indicators, relays with base, overload relay, 3 phase indicators, instrumental fan with filter, SMPS 24 volt dc. Pneumatic system: Solenoid valve, Air filter regulator, Pneumatic cylinder, Pressure controller Lubrication system: Manual oil injector Arbor (Tool holder) The Spindle motor from crompton greaves Penumatic vice with dove tail jaw Machine operations The machine operations are described as follows Boring and facing one time Threading as per a required sized taps Technical Specifications Max Boring diameter 40mm Max tapping diameter M36 G1 Drilling spindle motor 3HP and 4 HP Taping spindle motor 3HP and 4 HP Spindle rotation speed Drilling 1040, 1330 RPM Tapping 550, 860RPM Spindle feed travel 125mm(max) Spindle taper MT4 Distance between spindle 260mm Distance from spindle face to worktable 540/220mm Distance from spindle axis to column 260mm Worktable travel Lateral direction 280mm Longitudinal direction 100mm Dimensions 700x1000x1800mm Worktable size 680x240mm