Dyeing Accelerator Rd-100

Price:

Get Latest Price

In Stock

Product Specifications

| Appearance | Brown Transparent Liquid |

| Solubility | Soluble in Water |

Product Overview

Key Features

Special polyion compound

[General properties]

Ionicity: anion/nonionic

pH: 5-7

[Product features]

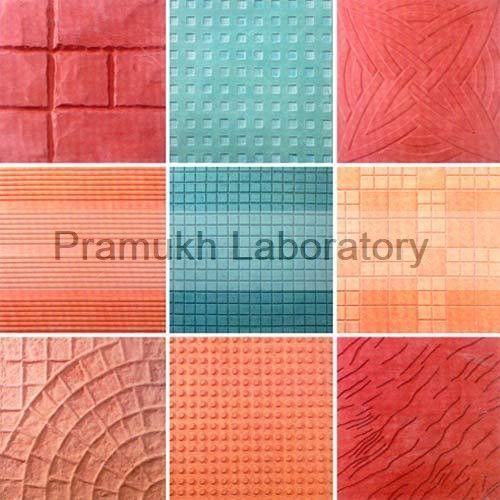

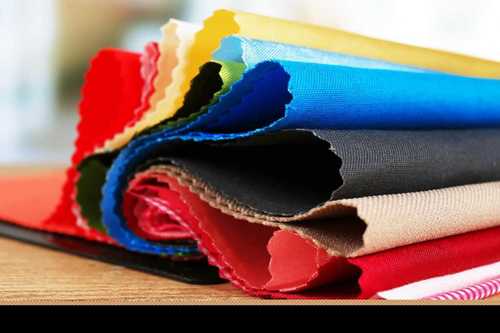

In the use of disperse dyes on polyester fiber dyed, can improve the degree of dyeing. The emulsion is stable, not easy specking. High leveling dye, and does not affect the fastness. This product is easy to remove through hot water treatment process, guide stain as carrier, can puffed in the dyeing process of polyester fiber, at the same time, and gradually put dye to fiber, and with the continuation of dyeing time play better role. First of all, in 40 ~ 70 a , heating speed control in 1 a / 1.5 ~ 2 min. With 45 ~ 60 a temperature, and in 70 a heat preservation 20 ~ 30 min, in order to make carrier to play its full role. Dyeing temperature reached 80 a , polyester fiber into the glass transition temperature, dyeing don't need carrier. Secondly, carrier method dyeing polyester heat preservation time more extend than the high temperature and high pressure method 1/3 to 1/2 (color from shallow to deep). Practice has proved, only in this way, can let disperse dye in has fully puffed of polyester, has more dyeing opportunity, at the same time, still can make many kinds of dyes increased migration rate, reduce mutual contamination phenomenon, improve the disperse dye absorption rate. Finally, to take off the carrier is very important. Must use warm water, cold water fully cleaning, try to reduce the residual? When cleaning, can add dispersion chelating agent 0.5 ~ 2 g/L which has better performance, not only improve the cleaning water quality, still can make the peculiar smell get the further disperse, dissolved in water and discharge off.

[Application]

First of all, in 40 ~ 70 a , heating speed control in 1 a / 1.5 ~ 2 min. With 45 ~ 60 a temperature, and in 70 a heat preservation 20 ~ 30 min, in order to make carrier to play its full role. Dyeing temperature reached 80 a , polyester fiber into the glass transition temperature, dyeing don't need carrier. Secondly, carrier method dyeing polyester heat preservation time more extend than the high temperature and high pressure method 1/3 to 1/2 (color from shallow to deep). Practice has proved, only in this way, can let disperse dye in has fully puffed of polyester, has more dyeing opportunity, at the same time, still can make many kinds of dyes increased migration rate, reduce mutual contamination phenomenon, improve the disperse dye absorption rate. Use in the jig dyeing machine, should be in the blank bath to add disperse dye low temperature Dyeing accelerant, running 4 rounds, and add other additives and dye. Finally, to take off the carrier is very important. Must use warm water, cold water fully cleaning, try to reduce the residual? When cleaning, can add dispersion chelating agent 0.5 ~ 2 g/L which has better performance, not only improve the cleaning water quality, still can make the peculiar smell get the further disperse, dissolved in water and discharge off.

[Usage]

After add water to emulsify Dyeing accelerant, then add to the dye VAT, after stir five to ten minutes fully diluted, then successively join the dyes and additives to bath, adjust PH value for 5 ~ 5.5, then heating to dyeing temperature, heat preservation to dyeing process completed, cooling, eliminate dye solution, use cold water washing, then through reduction washing and drying, can remove residual Dyeing accelerant easily. Usage: must according to the color and lustre of dyeing requirement, dosage and depth of color is proportional, its dosage general between in 0.5 ~ 2.5 g/L.

[Packaging and storage]

125 kg/ polyethylene drum, seal save in a cool and dry place, quality guarantee period 6 months.

Company Details

Honghao (HT Fine) Chemical Co., Ltd. Bulesign System Partner, is a large scale high-tech textile printing & dyeing auxiliaries manufacturer in Guangdong Province. Our main products are Pretreatment auxiliary, Dyeing auxiliary, Continuous process auxiliary, Hand finishing and Functional finishing agent, Washing agent etc., all products comply with the environmental standards and pass the SGS and other international certificates.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

180

Establishment

2005

Working Days

Monday To Sunday

Certification

OEKO-TEX

Related Products

Explore Related Categories

Seller Details

Guangdong, Guangdong

Sales Executive

Ms Annie Liu

Address

Comprehensive Building, No. 13 Chuangxin Road, Jianggu Fine Chemical Industrial Area, Jianggu Sihui. Guangdong, Guangdong, 511800, China

auxiliary chemicals in Guangdong

Report incorrect details