Product Overview

Key Features

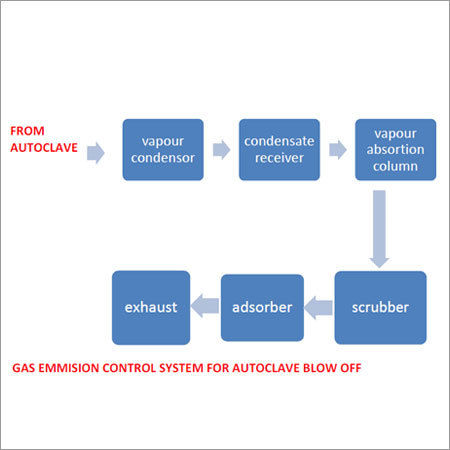

EFFECTIVE EMISSION CONTROL SYSTEM FOR AUTOCLAVE BLOW OFF: NSIE is also supply Effective emission control system, s required for the for Reclaim Rubber Autoclave blow-off as per pollution control norms. Exhaust gas coming out from Rotary Autoclave have the following constituents: Organosulfur compoundsPetroleum oil fractionsWater vapourParticulatesAir with all its constituents. A full proof integrated system is required to control the emission and to treat the condensate water. TYPES OF EMISSION AND ITS PRIMARY CONTROL METHOD: 1. Organosulfur compounds - Through Absorption and Adsorption. 2. Petroleum oil fractions - Condensation, Absorption and Adsorption. 3. Water vapour - Condensation 4. Particulate matter - Impingement separation, Scrubbing EMISSION CONTROL SYSTEM: The exhaust gas discharged from the Autoclave is directed to Vapour Condensers 2 Nos. arranged in series, where the condensable water vapour and the petroleum oil fractions will condensate and the condensate is collected from the two phases in a common Condensate Receiver. The Condensate Receiver is also having particulate impingement separation arrangement from the remaining gaseous discharge. The oil phase condensed is reused in the Autoclave and the water phase condensate is to be treated separately for reuse as machine cooling system make-up water. The remaining gas which contain odorous organic compounds, oil fractions and not-condensable is passed through packed vapour absorption column using suitable absorbent in a closed circuit. The gaseous discharge leaving the vapour absorption column contain light petroleum oil and traces of organic matter is passed to the scrubber where the concentration of undesired emission is achieved. The scrubbed gas finally directed to Absorber where the minute traces of organic compounds and light petroleum fractions are adsorbed. The discharge left is burnt off. COMPONENTS OF EMISSION CONTROL SYSTEM: VAPOUR CONDENSERSCONDENSATE RECEIVERVAPOUR ABSORBITION TOWERSCRUBBER TOWERWATER CIRCULATION PUMPSCRUBBING WATER STORAGE TANK IN PROCESSABSORBITION TOWERINTER CONNECTING PIPING BETWEEN THE SYSTEMS.

NSI EQUIPMENTS PVT. LTD., Established in 1965 at Chennai in Tamil Nadu, is a leading Manufacturer,Supplier of Machineries in India. NSI EQUIPMENTS PVT. LTD. is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Emission Control System, NSI EQUIPMENTS PVT. LTD. has made a reputed name for itself in the market with high-quality Emission Control System, Rubber Cracker Mill, Rubber Mixing Mill, etc.

Focusing on a customer-centric approach, NSI EQUIPMENTS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from NSI EQUIPMENTS PVT. LTD. at Trade India quality-assured products.