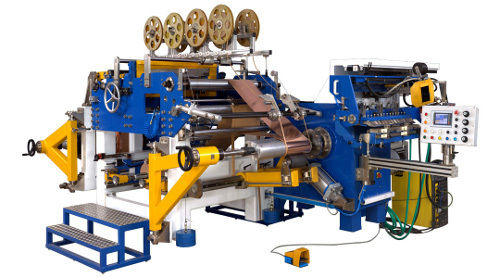

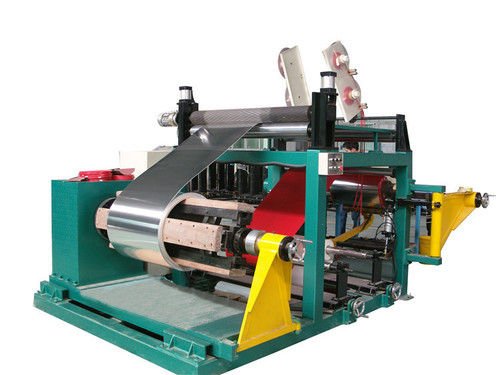

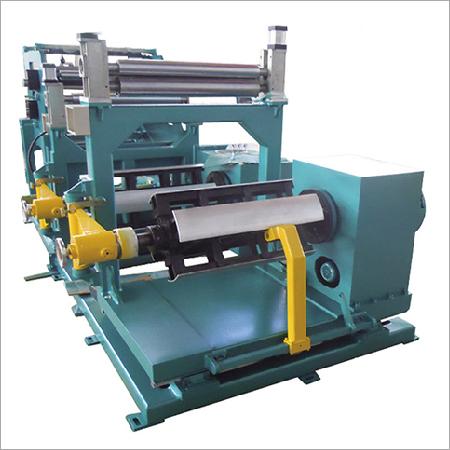

Foil Winding Machine - Advanced Foil Winding For Distribution Transformers | Features Stable Decoiler Tension Control, Plc Automation, User-friendly Interface, 30 Data Storage Capability, Network Communication Function

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Plc | Supported |

| Tension Control | Pneumatic |

| Capacity | Variable |

| Features | Stable Tension, Precise Control, Easy Operation, High Efficiency, Data Storage, Network Connectivity, Servo Adjustment |

Product Overview

Key Features

Foil winding machine is suitable for foil winding of all types of small and medium sized distribution transformer, instrument transformer, reactor coils and similar process foil winding. Especially suitable for the amorphous alloy transformer and wound core transformer rectangular foil winding.

Main Features:

1. The tension of the decoiler is stable and ita s controlled by pneumatic element. Foil and layer insulation tape whether in the winding or back are applied to a constant tension to avoid loss caused by the coil tightness. Stepless adjustment of the pressure size ensure that the whole winding process constant tension.

2. Adopts our researched and developed source program and operation program, all production factors of winding, error correct, circle control, etc. Different instructions are supported by PLC control system after calculation. It is carried out and achieved by each system.

3. Operating person only touch the screen of computer-human interface and input related working parameter, the same specification workpiece can be finished processing in large quantity.

4. It is also operated by manual through control button, including inching, continuous moving.

5. The system can store up to 30 sets of coil data for easy operation. The counter can count the winding process manually, when only wind the insulating layer, you can stop counting conveniently.

6. The equipment has network communication function, easy to upgrade the system and follow-up automation program update maintenance.

7. With automatic adjustment of the servo function.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

130

Establishment

1995

Working Days

Monday To Friday

Payment Mode

Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Director

Mr Owen Ge

Members since

10 Years

Address

Cangzhou Industrial Zone, Cangzhou, Hebei, 061000, China

foil winding machine in Cangzhou

Report incorrect details