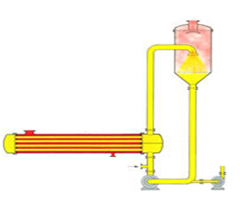

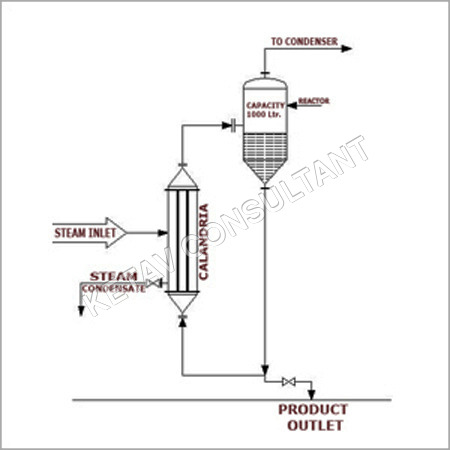

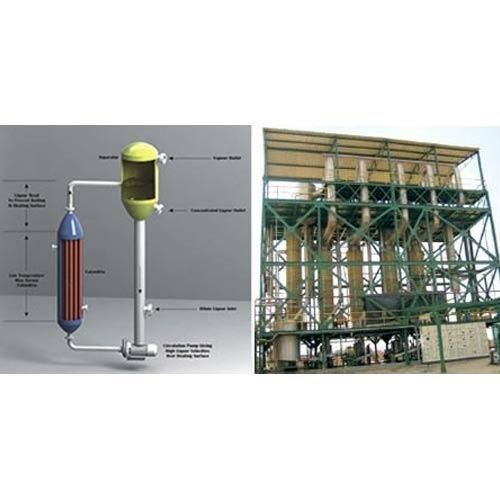

Forced Circulation Evaporators - High-efficiency Design For Extended Operation | Low Scaling, Reduced Operation And Maintenance Costs, Ideal For Distillery Effluent And High Concentration Materials

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Forced recirculation evaporator can be run for 40-50 days without any scaling, whereas falling film evaporator can only be run for 20 hrs only. 4 hours are required to clean the falling film evaporator daily

Operation and Maintenance Cost reduction due to lower usage of chemicals, steam and power consumption required during preventive maintenance and cleaning

The design capacity of the plant is lesser with respect to falling film evaporator

Despite of having high power consumption in forced recirculation evaporator, processing cost per lit of distillery effluent is less than falling film evaporator

Useful for concentration of inversely soluble material or for material which is susceptible to scaling or crystallizing like distillery effluent, mango/tomato juice, Malt concentrate (70% TDS)

Applications:

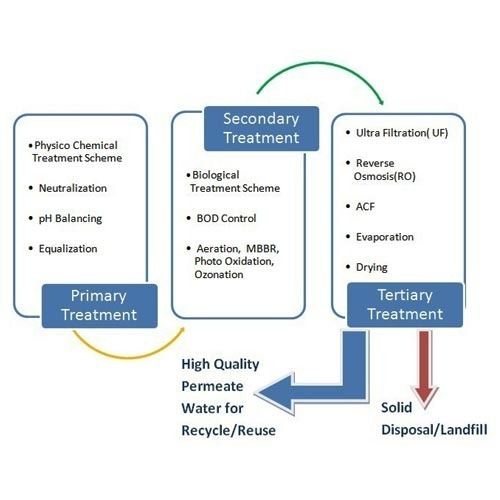

Effluent Treatment Plants

Malt mix slurry

Tomato paste

Mango pulp paste

Sugar Syrup

Glucose

Distillery effluent

High Concentration Requirements

Company Details

Focusing on a customer-centric approach, Raheja Ecotech Engineers Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Get Industrial Evaporators from Raheja Ecotech Engineers Pvt. Ltd. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

5

Establishment

2016

Working Days

Monday To Sunday

GST NO

07AAICR1601D1ZW

Related Products

Explore Related Categories

Seller Details

GST - 07AAICR1601D1ZW

New Delhi, Delhi

Director

Mr. Sidhant Raheja

Address

C2, Centumu Rd, Block C, Lajpat Nagar III, New Delhi, Delhi, 110024, India

Report incorrect details