Fruit Shell And Fruit Pulp Pellet Production Line

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 1 Ton/Hour |

| Power | 145 Kw |

| Pellet Size | 6-10 Mm |

| Workshop Area | 800 M² |

| Material | Steel |

| Grinding Mill Type | Hammer Mill |

| Pellet Mill Type | Mzlh420 |

| Features | High Efficiency, Low Cost, Eco-Friendly, Easy Operation, Customizable, High Quality, Clean Process, Durable Design |

Product Overview

Key Features

Definition of fruit shell and fruit pulp pellet production line:

The fruit shell is used as raw material, which is solidified and extruded into high-density biomass particles by pretreatment and processing. The fruit shell and fruit pulp fuel pellets can be used for burning, barbecue, and fireplace heating, and the combustion efficiency is over 80%; and the sulfur dioxide, ammonia nitrogen compounds and dust generated are less. Biomass fuel pellet is clean and hygienic, easy feeding, reduces the labor intensity of workers, greatly improves the labor environment, and enterprises will reduce the cost for labor.

Raw materials:

There are mainly rice shells, peanut shells, melon shells, coconut shells, bran and so on

Process introduction:

After the shell is grinded by hammer mill, then it is granulated. The processed finished granules are 6-10mm in diameter, and the granules are cooled and packaged for transportation and sale. When the fruit shell and fruit pulp pellet complete project is with 1 ton per hour capacity, the total power of the equipment is about 145kw, and the workshop covers an area of 800m2, which contains raw material warehouse and finished product warehouse. The whole line is compact in design, reasonable in structure and meets environmental protection requirements. And can be customized design according to customer requirements.

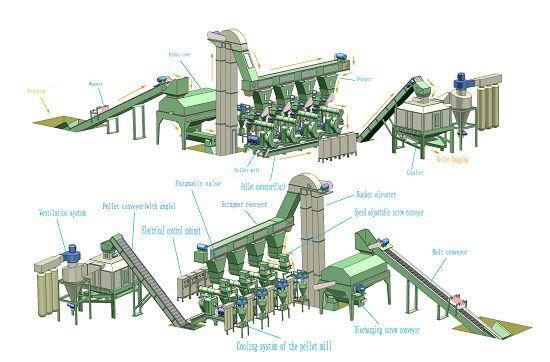

Procedure drawing :

Process diagram of complete fruit shell and fruit pulp pellet engineering process line:

Grinding section-----Pelleting section----- Cooling & Bagging section

Process section:

Grinding section:

The grinding section of the fruit husk pellet complete project consists of a plurality of auxiliary equipment such as cyclone and bag filter, and the grinding work has no dust discharge. After grinding, it is transported and pneumatic transmission by the fan suction air pressure. The size of the powder is generally about 3-4 mm. The hammer mill is a water droplet type structure with high grinding efficiency; the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade; the direct transmission mode of the motor is adopted, the transmission efficiency is high, and the maintenance is convenient.

Pelleting section:

One set MZLH420 biomass pellet mill was designed in the pelleting section. The diameter of biomass pellet is 6-10mm, and the biomass pellets have the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier. The fruit husk pellet complete project has obvious advantages in the pelletizing section: the pellet mill is equipped with a forced feeder to force feeding into the ring molding chamber, which can make the pellet mill run smoothly, do not block the materials, and produce efficiently. Specially design of broken screw feeding, so that the poor flow raw materials smoothly feeding.

Cooling & Bagging section:

In cooling section of fruit husk pellet complete project , we use cooler to reduce pellets temperature and decrease pellets moisture, low energy consumption, easy operation, high automatic degree, through the cooler cooling, pellets temperature is not higher than ambient temperature 5 a , after cooling the pellets moisture around 8-10%, particle density 650-750kg/mA .

Company Details

Focusing on a customer-centric approach, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2003

Related Products

Explore Related Categories

Seller Details

Changzhou, Jiangsu

General Manager

Mr. Zhi Liang Chen

Address

#6 Chenyang Road, Jiangsu Zhongguancun Science And Technology Industrial Park, Liyang, Changzhou, Jiangsu, 213300, China

biomass pellet plant in Changzhou

Report incorrect details