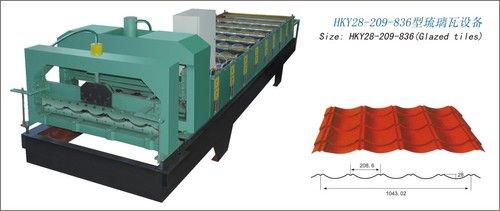

Glazed Tile Roll Forming Machine - High Grade 45# Steel, 1000mm Coil Width, 0.2-0.6mm Thickness, 15 Forming Steps | Advanced Plc Control, Hydraulic Cutting Precision, Durable Decoiling System

Price:

Get Latest Price

In Stock

Product Specifications

| Coil Width | 1000Mm |

| Effective Width | 828Mm |

| Thickness | 0.2-0.6Mm |

| Motor Power | 7.5Kw/5.5Kw |

| Forming Steps | 15 Steps |

| Roller Material | 45# Steel |

| Cutting Type | Hydraulic |

| Features | High Precision, Durable Rollers, Efficient Forming, Easy Operation, Auto Cutting, Precise Cutting, High Output, Low Maintenance |

Product Overview

Key Features

1. Decoiler

Manual decoiler

Capacity: 5 t

Manual expansion

Passive uncoiling

Film covering device :

The device adopts high grade 40Cr material, with numerical control processing, and surface with heat treatment, and then polished by manpower, in order to make sure the precision and smoothness of filming.

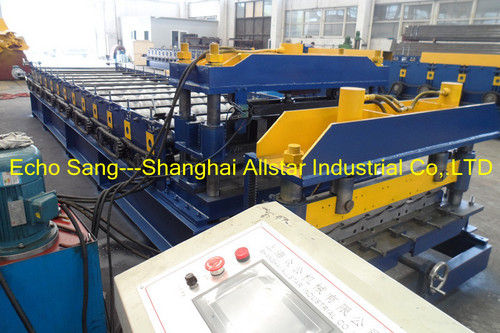

Roll forming machine :

Raw material: color steel or galvanized steel

Coil width: 1000mm

Effective width: 828mm

Thickness: 0.2-0.6mm

Main motor power: 7.5kw

Forming steps: 15 steps roll forming, and 1 step for film coating.

Main frame material: welded structural steel

Thickness of side plate: 18mm

Roller material: high grade 45# forge steel, polished and coated with 0.05mm hard chrome.

Transmission: 1.2 " chain transmission

Chain material: high grade 45# steel, headed and quenched HRC 45-500

Principal axis diameter: 70mm

Principal axis material: high grade 45# steel

Pressing & cutting device and hydraulic station

Type of cutting: hydraulic cutting

Hydraulic motor power: 5.5kw

Blade material: Cr12 with heat treatment HRC 50-600

Cutting length error: +/- 2mm

Electrical system

Electrical control: Panasonic PLC

Encoder frequency electrical control: Omron brand

Touch screen: Panasonic brand

Transducer: ABB

Size of PLC control board: 700mm*300mm*1000mm

Voltage: 380V 50Hz 3Ph (or as buyer's local require)

Product supporter

To support the formed sheet

Material: channel steel

Length: 5m

Company Details

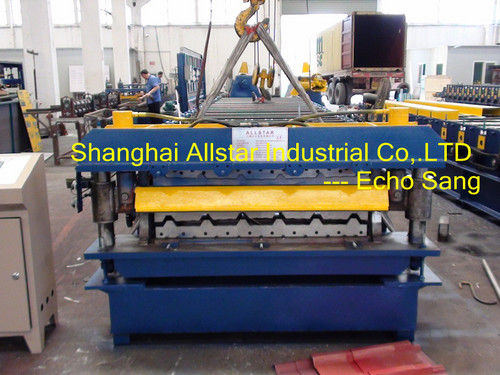

Focusing on a customer-centric approach, Shanghai Allstar Industrial Co,.Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Roll Forming Machinery in bulk from Shanghai Allstar Industrial Co,.Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2003

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Trencin, Shanghai

Ms. Echo Sang

Address

No.16 Xinshun Road, Xinnong Industrial Zone, Zhujing Town, Jinshan District, Trencin, Shanghai, 201503, China

roofing tile roll forming machine in Trencin

Report incorrect details