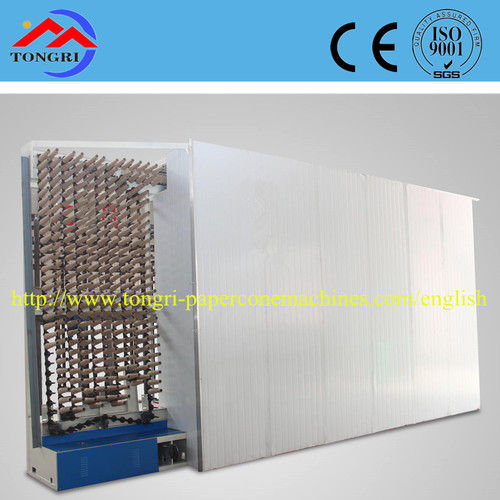

Good Service Automatic Paper Cone Making Machine - 14000mm X 6000mm X 3800mm | 49.2kw Power, Plc Control, 48 Pcs/min Production Speed, Adjustable Color Options

Price Trend: 63000.00 - 75000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Other |

| Capacity | 14000 Kilogram(Kg) |

| Computerized | Yes |

| Control System | PLC Control |

| Cutting Speed | 5 m/m |

| Cutting Size | 4Adeg20 5Adeg57 |

| Cutting Thickness | 2-8 Millimeter (mm) |

| Voltage | 380 Volt (v) |

| Power | 49200 Watt (w) |

| Weight (kg) | 14000 Kilograms (kg) |

| Dimension(L*W*H) | 14000*6000*3800 Millimeter (mm) |

| Color | adjustable |

| Warranty | 1 year |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 1 set per month Per Month |

| Delivery Time | 45 working days Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Container |

| Main Export Market(s) | Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia |

| Main Domestic Market | All India |

| Certifications | CEISO9001 |

Product Overview

Key Features

TRZ-2017 automatic conical paper tube production line need no manual operation from raw paper to paper tube product. The whole production process is controlled by PLC programming, main engine transmission uses cam timing mechanism. Each position takes double speed variable frequency control technology. Also the none mechanical abrasion photoelectric control, approaching control and pneumatic delay control, which realize the mechanical and electrical integration. Suitable for the production of conical tube with various specification.

Process

Rolling, internal and external printing, edge grinding, cutting, reeling, drying, finishing, cutting V shaped opening, opening processing, pressing, grinding, galling, finishing

Main Parameter

Power: 49.2KW

Speed: 48 pcs/min

Size: 14000mm*6000mm*3800mm

Operator: 1

1. TRZ-2017 automatic paper cone production line reeling part

TRZ-2017 automatic conical paper tube reel is suitable for conical tubes of various specification. After hanging the paper roll, internal and external printing, edge grinding, cutting, reeling, head cutting, the semi-finished paper tube will be sent to the dryer. It takes double speed variable frequency control technology. The reeling speed can be adjusted automatically. The whole process is eased by connecting with the dryer.

Main parameter

For conical tubes with various taper and calibre

Speed: 48pcs/min

Power: 13.27kw

Size: 6080mm*2240mm*1500mm

2. TRZ-2017 automatic paper cone production line after finishing part

TRZ-2017 after finishing part is designed to turn the semi-finished product into conical paper tube after V cutting, grinding, pressing, reversing and galling.

The speed can be adjusted freely with over-load protector and automatic stopping equipment when the improper operation happens to guarantee the safety and stability and lower the waste rate. The after finishing machine can also be used individually.

Main parameter

For conical tubes with various taper

Speed: 48pcs/min

Air pressure: 0.3-0.4 mpa

Size: 2600*1600*1580mm

3. TRZ-2017 automatic paper cone production line drying part

The TRZ-2017 auto-temperature control dryer uses chain--type circulation drying. After setting up the temperature, the heat can be controlled, maintained and adjusted freely, featured low consumption and high outcome. Paper tube can be feed and collected automatically after connecting with other equipment.

Main parameter:

Speed: 48 pcs/min

Power: 10.1-24.5 kw

Size: 5620mm*1700mm*3800mm

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1990

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinan, Shandong

Foreign Trade Salesman

Ms. Kathy

Address

Tongri Industry Park, Wande Town, Changqing District, Jinan, Shandong, 250022, China

paper cone machine in Jinan

Report incorrect details