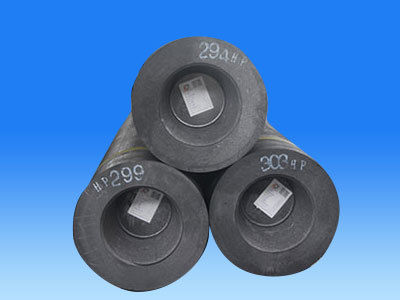

Graphite Electrode - High Grade Petroleum Coke & Anthracite Coal, Excellent Electrical Conductivity & Thermal Shock Resistance

Price: 1 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| FOB Port | China Port |

| Supply Ability | 60,000 Tons Per Year |

| Delivery Time | Stock or Within 1 Month Months |

| Packaging Details | As Required By Customer |

| Main Export Market(s) | Australia, Eastern Europe, Middle East, Western Europe, Central America, Africa, South America, Asia, North America |

| Certifications | IO9001:2008 |

Product Overview

Key Features

Graphite Electrodes are prepared from high-grade Petroleum Coke and Anthracite Coal, employing Coal Tar Pitch as agglutinant and lubricant with the help of the process of calcination, mixing, kneading, extruding and graphitizing.

Graphite Electrodes embody the properties of better electric conductivity and chemical stability, high electrochemical strength, zero impurity, no reactive effect, seismic performance in increasing temperature. Graphite Electrodes are basically preferred to steel-making in electric arc furnaces, mineral hot furnaces and electric resistance furnaces.

This type of electrodes conducts electric current into the furnace. Electric current causes arc in the smelting pit, when the temperature goes up to about 2000A C, melting action starts. Our series of Graphite Electrodes is preferable to the common furnaces and heavy-duty furnaces with greater voltage and less arc. Graphite Electrodes can be divided into three classes.

Key Features:

Used in forming of bevel and removing defects in castings by an arc or gas process

Excessive heat sustaining capability

Provides high level of electrical conductivity

Eco-friendly nature with high calorific value

Applications

These electrodes are used for steel making in electric arc furnace and ladle refining furnace .

These Electrodes are used for producing yellow phosphorus, industrial silicon, corundum and so on in electric smelting furnace.

Graphite Electrodes: mainly used in simple-level electric ovens for melting steel, silicon and yellow phosphorus.

Graphite Electrodes: primarily have application in high power electric ovens for melting steel.

Graphite Electrodes: basically have application in high-power electric ovens for melting steel.

Grades

Regular power (RP)

Impregnated (high density)

High power (HP)

Super high power (SHP)

Ultra high power (UHP)

Programmable properties

Good electrical conductivity. High resistance to thermal shock. High mechanical strength.

Advantages of Graphite Electrode

Low Electrical Resistance,High Current Load Capacity, Low Coefficient of thermal expansion (C.T.E.), High Flexural Strength, High Thermal Shock Resistance.

Related Products

More Product From This seller

Company Details

Focusing on a customer-centric approach, HENAN SOONHI INDUSTRIAL CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Solar Panels in bulk from HENAN SOONHI INDUSTRIAL CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

100

Establishment

1997

Working Days

Monday To Friday

Payment Mode

Cash Advance (CA)

Certification

IO9001:2008

Explore Related Categories

Seller Details

Zhengzhou, Henan

Accepts only Foreign inquiries

Sales Manager

Mr Kingsley

Address

9-405, Unit2, TianDi Wan, YingCai Street HuiJi, Zhengzhou, Henan, 450000, China

graphite electrodes in Zhengzhou

Report incorrect details