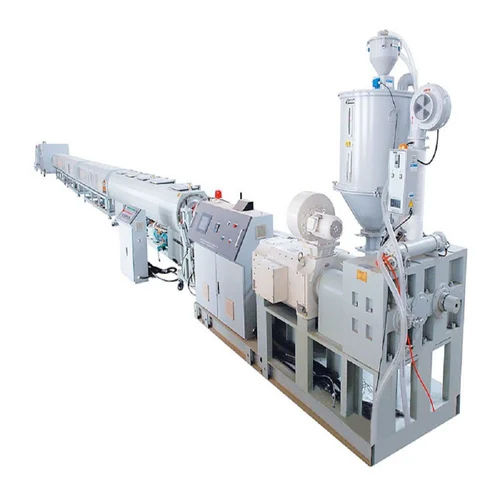

Hdpe/pp Spiral Corrugated Pipe Production Line - 35,000x5,000x1,250 Mm | Automatic Plc Control, High Speed Extrusion, Lightweight, Corrosion Resistant, High Efficiency

Price Trend: USD 19500-20000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | HDPE/PP |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Drive Type | Direct |

| Power | 220-380 Watt (w) |

| Weight (kg) | 25000 Kilograms (kg) |

| Dimension(L*W*H) | 35000*5000*1250 Millimeter (mm) |

| Color | HUASU Standard Color |

| Warranty | 1 year of defects liability period |

| FOB Port | Qingdao,China |

| Payment Terms | Telegraphic Transfer (T/T), Western Union, Paypal, Others |

| Supply Ability | 150 Per Year |

| Delivery Time | 60 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Spiral Tube Machine/Spiral Tube Machinery/Spiral Tube Line/Spiral Tube Extrusion Line/Spiral Tube Extrusion Machine/Spiral Tube Extrusion Machinery/Spiral Tube Production Line/Spiral Tube Making Machine/Spiral Tube Making Machinery/Single Wall Corrugated Tube Machine/Single Wall Corrugated Tube Machinery/Single Wall Corrugated Tube Line/Single Wall Corrugated Tube Extrusion Line/Single Wall Corrugated Tube Extrusion Machine |

| Main Export Market(s) | South America, Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Asia, Central America |

| Main Domestic Market | All India |

| Certifications | CE ISO9001 |

Product Overview

Key Features

PE spiral CORRUGATED pipeA has characteristics of light weight, high strength, corrosion resistance, anti-bend, and non-leaking, bypassing the obstacles and so on. This kind of pipe can substitutes iron pipe, rubber pipe and PE pipe (PE strengthen screw soft pipe, PE double wall corrugation pipe). These pipes are mainly applied in the field of agricultural irrigation protection of cable and ventilation and so on.

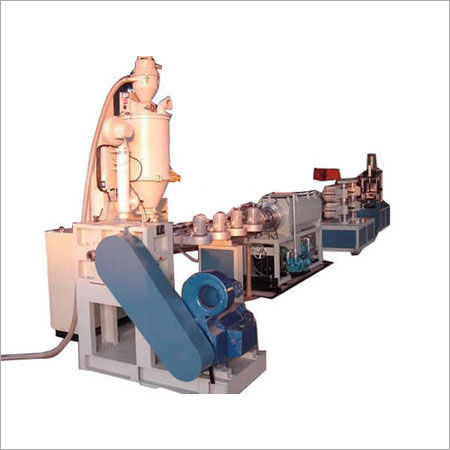

PE spiral CORRUGATED pipe extrusion lineA produced byA Qingdao HUASU MachineryA Fabricate Co., Ltd adapted to the development trend. This pipe line has many advantages such as high production speed, high degree automation, stable working performance, large output and high efficiency and so on. It mainly applied in the field ofA protection of cable and ventilation and so on.

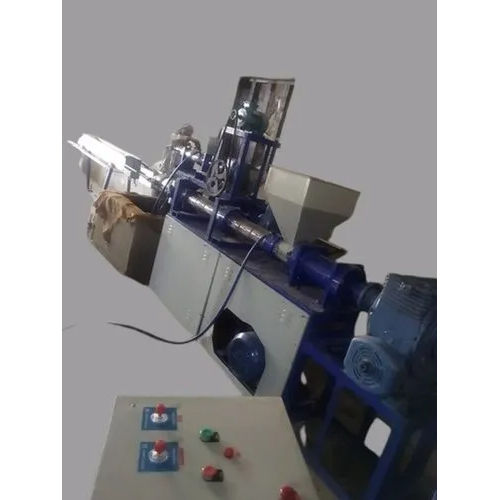

Process flow: Raw material + additive a mixing a vacuum feeding machine a hopper dryer a single screw extruder a a CORRUGATOR(foaming machine)a haul-off machine a cutting machine a winder.A

PE CORRUGATED spiral pipe production line mainly includes single screw extruder, die,A A mold block, CORRUGATOR(foaming machine) , haul-off machine, cuttingmachine andA winding machine.

Single Screw Extruder: Single screw extruder is especially used for polyethylene material which possesses effective plasticizing and high speed extrusion.

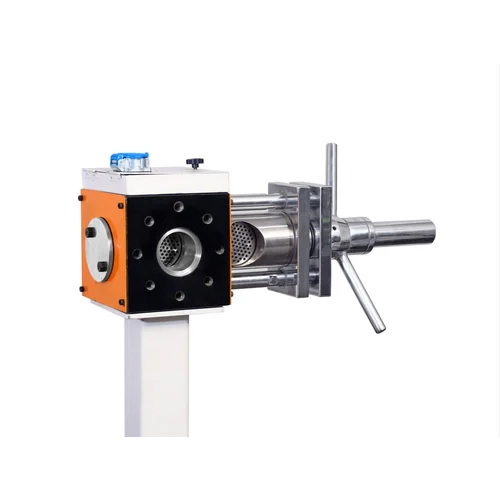

Die: Standard designed spiral die head and reasonable channel are applicable to produce pipes with smooth inside and outside surface. The helix apportionment style shunt body and big flow space assure the melting material having enough staying time. Best design of low melting temperature caused in little internal pipe stress, smoothing inner and outer pipe surface.

Corrugator:A Corrugator is adopted horizontal structure with chain type transmission,equipped with open water cooling system and vacuum forming system. It greatly increases the production speed. The belling on line function decreases investment cost and improves production efficiency. Mold moving adopts synchronous upper and lower mechanical drive system and advanced self-lubrication system. It assures moving accuracy and corrugated pipe quality stability.

Haul-off Machine: Frequency convertor, pneumatic clamping, and simultaneous running with the whole production line.

Cutting Machine: High accuracy, low noise and fixed length cutting.

Winding Machine: Torque motor and gear reducer

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2001

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Qingdao, Shandong

Manager

Mr Alan Jia

Address

Jiaozhou Bay Industrial Zone of Jiaozhou in Qingdao City Qingdao, Shandong, 266300, China

hdpe pipe machine in Qingdao

Report incorrect details