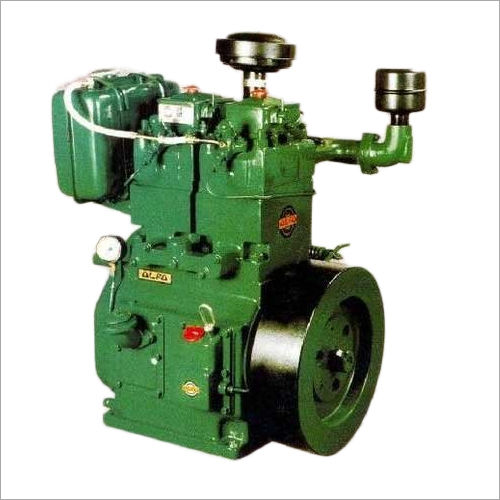

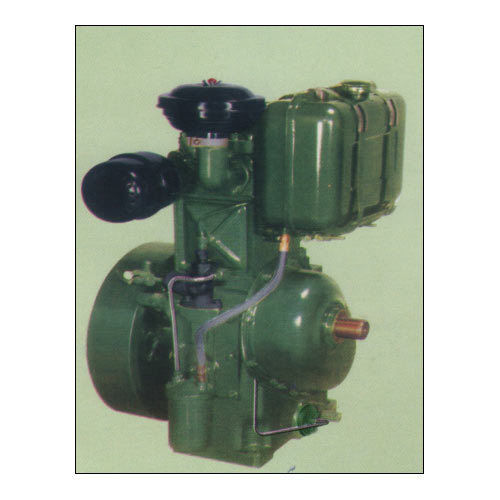

High Speed Diesel EnginesIncorporated with modern features as per industrial standards and requirements, we manufacture, supply, export and import a wide range of High Speed Diesel Engines. We are manufacturing vast range of high speed diesel engine for various industries. Offered high speed diesel engine is precision engineered, under the able guidance of quality controllers who ensures the ideal working and quality of these diesel engines. Our company is offering these High Speed Diesel Engines to our venerated customers at very cost effective price. Specifications: TECHNICAL DETAILS Engine Models GA 1 GT1 GT2 GM 8.5 GM 10 GM 20 No. of Cylinders 1 1 2 1 1 2 Bore X Stroke (mm) 80x110 87.5x110 87.5x110 95x110 102x116 102x116 Cubic Capacity (Lit) 0.553 0.661 1.323 0.78 0.948 1.896 Compression Ratio 16.5:1 17.5:1 17.5:1 17.5:1 17.5:1 17.5:1 Rated Output as perBS : 5514 / DIN :6271/ISO : 3046 1500 rpm kW(bhp) 3.7(5.0) 5.2(7.0) 10.4(14.00) 6.25(8.5) 7.4(1.0) 14.8(2.0) 1800 rpm kW(bhp) 4.4(6.0) 5.9(8.0) 11.8(16.00) -- -- -- Tourque at full load Crankshaft drive1500 rpm 0.023(2.4) 0.033(3.5) 0.066(6.70) 0.023(2.4) 0.047(4.8) 0.094(9.6) kNm (kgm) Camkshaft drive750 rpm 0.046(4.8) 0.066(6.70) 0.132(13.4) 0.046(4.8) 0.94(9.6) 0.118(19.2) SFS g / kWh (g/bhp - hr) at rated HP / 1500 rpm 251(185) Lub. Oil consumption 0.8% of fuel consumption Lub. Oil Sump Capacity(Lit.) 2.7 2.7 6.5 2.7 2.7 6.5 Fuel Tank capacity (lit) 7 7 10 10 10 10 Engine weight (dry) (Kg) 180 185 260 195 200 280 Light weight flywheel forPumpset application (Kg) 35 35 35 52 52 - Medium Weight flywheel forIndustrial Application (Kg) 43 43 43 52 52 - Heavy Weight flywheel forPG & or FEW. Starting arrangement (Kg.) 43 64.5 64.5 64.5 64.5 64.5 SPECIFICATIONS WITH STANDARD EQUIPMENT Net Wt. of std. Engine (Kg.) Gross Wt.(Kg.) 180 245 185 250 260 325 195 260 200 265 280 345 SPECIFICATIONS Type Vertical, totally enclosed, compression ignition, four-stroke cycle, cold starting, water-cooled diesels, twin cylinder. Combustion Open type combustion chamber in an aluminium alloy piston, in combination with long stem nozzle, resulting in low fuel consumption and easy starting. Fuel System Fuel is supplied to the fuel pump by gravity feed through an efficient paper element filter. Lubrication Force feed lubrication to main and large-end bearings and camshaft bush. Other working parts are splash lubricated. Bypass filter is provided for cleaning the lubricating oil. Cooling Engine cooling can be arranged for run-through water supply or cooling tank. Governing Class B1 . Rotation Standard rotation is clockwise; optional anticlockwise. Drive Standard power take-off is from the fly wheel side. Power take-off from gear end at half or full engine speed can also be provided. Starting The engine is designed for starting by hand. However, for twin cylinder engines 12V electrical starting arrangement for reverse rotation engines can be supplied, if specially ordered. Standard Equipment Starting handle, air cleaner, exhaust silencer, set of spares and tools. Optional Radiator, heavy flywheel, 12V electrical starting, lub. Oil pressure gauge, variable speed arrangement. Anticlock-wise rotation, extension shaft, flywheel housing SAE-3, SAE3 to SAE-5 adaptor, foundation bolts.