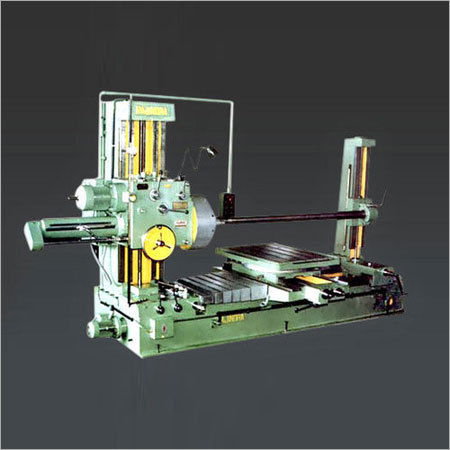

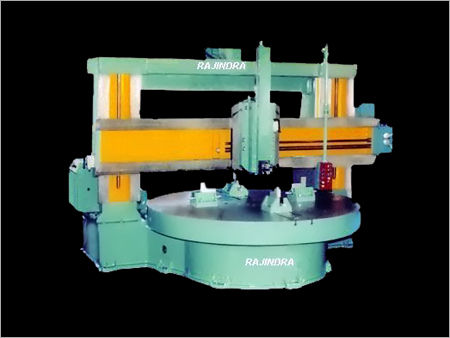

Horizontal Boring, Milling Drilling Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Spindle Diameter | 100-120 Mm |

| Morse Taper | 6 |

| Spindle Speed | 9 |

| Spindle Speed Range | 12-242 Rpm |

| Longitudinal Movement | 550-600 Mm |

| Material | Alloy Steel |

| Weight | 11000-18000 Kg |

| Features | High Precision, Versatile, Durable, Easy Maintenance, Efficient, High Output, Safe Operation, Accurate, Robust |

Product Overview

Key Features

Horizontal Boring, Milling Drilling MachineRajindra all geared Horizontal Boring, Drilling & Facing Machine is a typical machine tool for soughing and finishing operation within the range of Boring, Drilling, Facing & Milling. It is capable of the widest application and is recommended for almost all classes of work. The machine is real achievement, for its leads directly to improve accessibility and simplified maintenance and makes it easy to produce a quality machine tools matched to the needs of the factory for which it is intended. The various mechanisms are enclosed and all the external surfaces are smooth and easily cleaned. The massive construction is a guarantee to withstand fully all the working stresses. The design of the Boring Machine is a guarantee of stiffness, accuracy and large output.The casting is done with the mixture of 25% steel etc and seasoned for at least six months to have proper Brinnel Hardness.The machine is manufactured to Grade-1 limits of AccuracyThe main Bed ways and Pillars etc. are accurately finished with Grinding Machine.Longitudinal & Cross Table Traverse, Vertical travel of Headstock and Boring Stay Support are provided with Rapid Movements as well as Feeds.All gears are precision cut to ensure smooth and silent running.Headstock and Boring Stay Support both travel simultaneously.The machine is manufactured according to Dr. Schlesinger's acceptance test chart.Special Arrangements: To set Rotary table perfectly at right angle.Safety Clutches (To Disengage):Facing MechanismSliding Mechanism of Cross Slide.Circular Table MovementSpindle Rod Longitudinal Movement.Spindle Rod Support Guide for vibration control.Boring head height setting adjustment by hand operated wheel fitted at the end of feed gear box motor.Hand operated lever attached to Headstock drive motor.Hand operated lever attached to Headstock drive motor and feel gear box for safe engagement of speed & feed respectively.Centralized control for easy operation.Technical Data

.

mm

mm

mm

Alloy steel work spindle hardened &

Ground-diameter

100

110

120

Morse Taper Number

6

6

6

Max. Longitudinal movement of the working Spindle

550

550

600

Number of spindle speeds

9

9

9

Range of spindle speeds

22 to 242

15 to 200

12 to 200

Longitudinal work spindle feeds nos.

9

9

9

Max. height of the spindle axis from table surface

1100

1150

1200

Min. height of the spindle axis from table surface

30

30

30

Dimensions of the Rotary table

1125 to 1400

1150 to 1400

1200 to 1450

Longitudinal table traverse

1650

1950

2050

Long. table traverse feeds (including one Rapid)

8

8

8

Transversal table travel feeds (including one

Rapid)

8

8

8

Vertical Headstock travel feeds (including one

Rapid)

8

8

8

Rotary table automatic feeds (including one Rapid)

.8

8

.8

Max. cross movement of the table

1200

1300

1500

Max. distance between stay bearing and the facing

head

2650

2750

2800

Facing head diameter

610

610

650

Weight approximate in kgs.

11000

14500

18000

Company Details

Focusing on a customer-centric approach, Rajindra Machinery Makers has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from Rajindra Machinery Makers at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1959

Working Days

Monday To Sunday

Certification

ISO 9001 : 2008

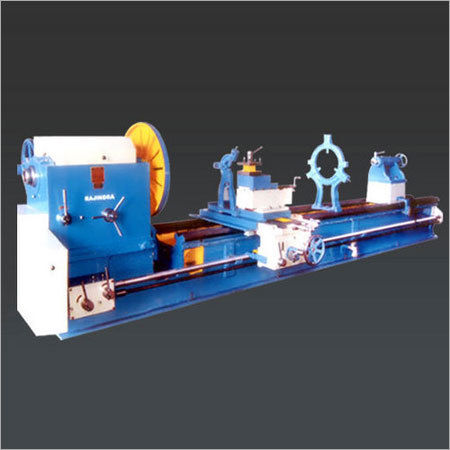

Related Products

Explore Related Categories

Seller Details

Batala, Punjab

Partner

Mr. Manbir Singh Rana

Address

GT Road Batala, Punjab, 143505, India

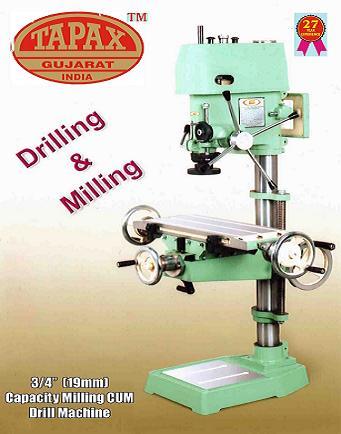

milling cum drilling machine in Batala

Report incorrect details