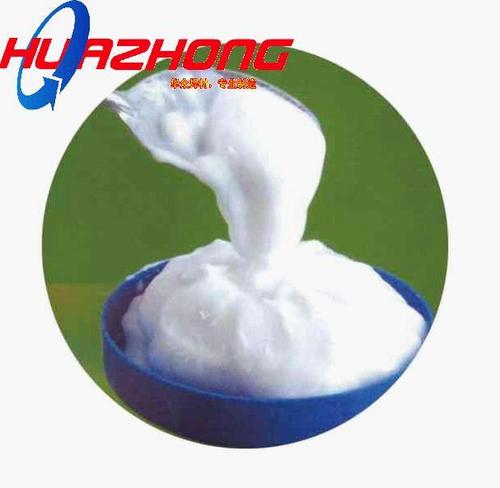

HZ-QJ305 100G Silver Solder Paste

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | shanghai |

| Payment Terms | Delivery Point (DP) Letter of Credit (L/C) Telegraphic Transfer (T/T) Paypal |

| Supply Ability | 500kg Per Day |

| Delivery Time | 7-15 work days Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | 100g/250g/500g/1kg bottle 10kg/15kg carton |

| Main Export Market(s) | Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa |

| Certifications | ISO |

Product Overview

Key Features

Features :-

Cleans the metals when they are joining while brazing and welding

High-temperature metal joining processes

Prevent oxidation of the base and filler materials

Acts as a wetting agent in the soldering process

Reducing the surface tension of the molten solder and causing it to better wet out the parts to be joined

Allows solder to flow easily on the work piece

Featuring better fluidity and permeability than other silver brazing pastes HZ-QJ305 silver brazing paste is a new type of researched and developed brazing flux gathering advantages from all kinds of welding flux.

Usages: HZ-QJ305 can work together with silverbased brazing alloysfor copper and copper alloys stainless steel nickel alloys diamond PCD at the temperature range of 600 to 850 A C in flame brazing resistance welding highfrequencybrazing furnace brazing.

Physical status : paste

Granularity : a 150I m

Density : 1.9-2.1

Standard : JB/T6045-92

Chemical composition: complex borate complex fluoborate activities water etc. No contain restricted compounds.

Characters: The flux is very stable chemically and physically. No precipitate caking or loss of activity and fluidity for long time storage. Featuring smooth surface and small welding seam HZ-QJ305 can replace similar foreign product.

Application areas: Refrigerator accessories compressor stone and wood cutter automobile accessories glass frame ornament and jewelry electric apparatus hardware tools etc.

Preparation: To optimize the result the work pieces should be cleansed thoroughly previous to brazing operation the surface should not be too rough or attached on metallic particle or dirt. Stainless steel work piece should not be scrubbed by steel wire brush.

Operation: Dip the work pieces into the paste or diluted paste before brazing.

Post treatment: the residue can be eliminated by merging the work piece into hot water on 10% mass fraction citric acid.

Caution: inesculent. Immediate water flashing is need if it is splashed into eye or mouth. Do not mix it with other impurity materials. After the packing is opened the paste can be hardened easily.

Company Details

Business Type

Manufacturer, Supplier, Fabricator

Employee Count

50

Establishment

2002

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hefei, Anhui Province

John Huang

Address

No.8 Guanqi Road Economic & Technical Development Area Hefei Anhui Province 230601 China

soldering fluxes in Hefei

Report incorrect details