Industrial Induction Heating Unit Application: Security

Price: 1000.00 USD ($)

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Payment Terms | Letter of Credit (L/C), Others, Telegraphic Transfer (T/T) |

| Delivery Time | 45 Days |

Product Overview

Key Features

EQUIPMENT APPLICATION

Workpieces that are heated in TERMOLIT units can be round, square (rectangular) and non-standard sections. Their diameter in the case of a rounded section can be from 5 mm to 400 mm. If the section of the workpiece is rectangular, it can measure 300 mm by 300 mm in a section.

Induction heater for forging is a more efficient solution than gas, oil and muffle counterparts. Enterprises using induction heating equipment are distinguished by high quality products, maximum productivity and minimum energy costs. Induction heating, respectively, can reduce the cost of production, save production time and reduce the harmful effects on the environmental atmosphere.

Heating equipment, based on the work of which induction heating, does not have such a side effect as the formation of scales and a decarburized layer on the workpiece. Therefore, the quality of the final product is noticeably higher than that of the one that has been processed using other heating methods. The heating temperature can be regulated by means of a frequency converter, which directly affects the depth of heating.

DESCRIPTION OF THE HEATING PROCESS

By dint of induction heating units, the metal performs are heated efficiently. At the heart of their work is induction. Induction heating is a non-contact operation, which consists in influencing the conductors, which are metal workpieces, of high-frequency currents induced by an alternating magnetic field.

The essence of the process is as follows: the workpiece is placed in an inductor, which with the help of a generator creates around itself a powerful electromagnetic field, which induces eddy currents in the workpiece, which it also warms up.

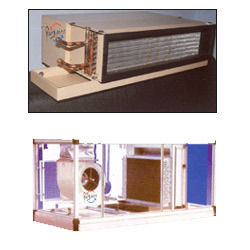

UNIT ARRANGEMENT

Induction heater for forging is a functional unit consisting of the following components:

1.THYRISTOR FREQUENCY CONVERTER;

2.HEATING POST, SUBMITTED BY INDUCTOR, OUTLET THROTTLE AND CONDENSER BATTERY;

3.CONTROL AND SIGNALING PANEL;

4.HEAT EXCHANGER.

The delivery set also includes mounting accessories and operating documentation. The customer can also order a water-cooled cable and a hardening transformer, complete with equipment.

ADVANTAGES OF INDUCTION HEATING UNITS

Heating units with induction heating method are the equipment:

a cWITH LESS DURATION OF THE PROCESS CYCLES THAN UNITS USING OTHER HEATING METHODS;

a cWITH CONTROLLED POWER TRANSMISSION;

a cWITH THE OPPORTUNITY OF CONTROL AND LOCALIZATION OF HEAT;

a cWITH OPPORTUNITY TO CONTROL THE TECHNOLOGICAL PROCESS;

a cWITH THE OPPORTUNITY TO CONTROL COOLING;

a cALLOWING TO RAISE THE PRODUCTION;

a cABILITY TO HEAVE SEPARATE PARTS OF TRAINING;

a cIMPLEMENTING OPERATIONS WITHOUT PHYSICAL CONTACT WITH BRAKES;

a cENABLING ENERGY AND SPACE ON PRODUCTION;

a cDIFFERENT BIG ACCURACY;

a cCAPABLE ON INTEGRATION IN PRODUCTION LINES;

a cWHICH THE UNIVERSAL TEMPERATURE IS POSSIBLE.

In addition, by purchasing such units for your own production, you will significantly improve the working conditions of your enterprise's workers. The main advantage of heaters of this kind is induction heating penetrating deep into the workpiece. The main advantages follow from this.

Company Details

Business Type

Exporter, Manufacturer, Producer

Employee Count

100

Establishment

1996

Working Days

Monday To Friday

Payment Mode

Cash Against Delivery (CAD)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Melitopol, Zaporizhia

Marketing And Sales Manager

Mrs. Ann A. Yurchenko

Address

Zindels str. 23, Melitopol, Zaporizhia, 72316, Ukraine

induction heating unit in Melitopol

Report incorrect details