Insulating Bricks - High-strength, Lightweight, Low Thermal Conductivity | Excellent Thermal Insulation & High Purity For Kiln Applications

Price:

Get Latest Price

In Stock

Product Overview

Key Features

800x600

Our offered Insulating Bricks are highly demanded in the construction of isolating chambers, rooms

and other places. We are the remarkable entity betrothed in exporting and

supplying quality assortment of bricks to our valuable clients. The offered bricks are processed

using premium grade raw materials with the aid of latest tools by skilled

professionals. Our product is quality tested under the supervision of experienced quality

controllers. The offered Insulating

Bricks can be availed

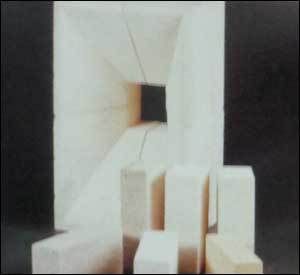

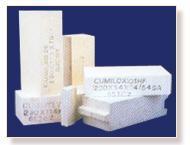

by our clients at affordable rates form us. Features of our Insulating Firebrick are Excellent strength at ambient and elevated temperaturesHigh compressive strengthEvery brick ground to precise dimensionsVery low levels of iron and other impurities (especially resistant to tough, reducing atmosphere conditions)Lightweight, energy-saving nature results in less heat loss, lowers operating costs, and allows for thinner furnace liningsLower heat storage than denser refractoriesHeats quickly and economically to kiln's operating temperatureCools fast to speed periodic operationsAvailable in custom designed shapes upon request Kiln is the heart of any ceramic process, and hence the proper functioning of the equipment is of prime importance. Over the years, there has been a steady increase in technical demands in terms of shorter cycle times, homogeneity of temperature and regulation of atmosphere in the kiln for improvement in product throughput and quality and increased fuel efficiency. Refractories play a major part in satisfying the above criteria; hence, in order to cope with ever growing demands of the market, CUMILAG 26, which can withstand temperatures up to 1400A A C, is extremely light and porous and has excellent thermal insulating properties. It is normally recommended as back up lining in kilns. CUMILAG 29, which is a hot face insulating refractory of high purity, is designed for prolonged and has service at 1450A A C and intermittent operation at a service temperature of 1500A A C. The uniqueness of this refractory is its uniform pore structure, that makes it an ideal material for high temperature applications. It can be cut to any desired shapes. Product Data: FIRED CUMILAG 26 CUMILAG 29 CUMILAG 32 Chemical Analysis - (%) A12O3 Max. 55 55 72 SIC Min SiO2 Max 40.00 40.00 24.00 Fe2O3 1.00 1.00 0.50 CaO Max Physical Properties Max Hot face Temp. - A A C 140 1550 1750 Max. Grain Size - mm PCE Orton Equivalent Bulk Density Dried at 110A A C/24 Hr. (gm/cc) Min. 0.90 Max 1.10 Max 1.35 Max Apparent Porosity (%) Max Modulus of Rupture (kg/sq. cm) Min. @ Room Temp. @ 1250A A C @ 1350A A C Reheat Change (%) @ 1450A A C for 6 hrs. Cold Crushing Strength (kg/sq. cm) Min. Dried at 110A A C/24 hr. 15 35 35 Fired at 700A A C/3hr Fired at 800A A C/3hr Fired at 1000A A C/3hr Fired at 1200A A C/3hr Fired at 1450A A C/3hr Fired at 1550A A C/3hr Permanent Linear Change (%) Max. Fired at 800A A C/3hr Fired at 1000A A C/3hr Fired at 1350A A C/24hrs. -1.00 Fired at 1450A A C/24hrs. -1.00 -1.50 Fired at 1550A A C/3hr Fired at 1650A A C/24hrs. Thermal Conduct. (w/m A A K) Max. at hot face 800A A C 0.42 0.44 0.49 at hot face 815A A C at hot face 1000A A C 0.52 0.54 0.64 at hot face 1200A A C 0.52 0.63 0.65 Application Area: Unique Combination of Chemical, Mechanical Stability and Insulating Properties. Used as Hot Face & Back up Linings for Kilns & Furnaces. Lightweight, Low Thermal Conductivity & Heat Storage. Can be Directly Exposed to Flame & Combustion Products. Note : All values are based on test results on standard bars of size 150 x 40 x 40 x mm and cubes of 75 x 75 x 75 or 80 x 80 x 80 mm. Thermal conductivity is done on std. bricks of size 230 x 115 x 75 or 65 mm.

Company Details

Focusing on a customer-centric approach, SUPRA ASSOCIATES has a pan-India presence and caters to a huge consumer base throughout the country. Get Insulation Material from SUPRA ASSOCIATES at Trade India quality-assured services.

Business Type

Exporter, Importer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

10

GST NO

27AAOFS2501G1ZA

Related Products

Explore Related Categories

Seller Details

GST - 27AAOFS2501G1ZA

Mumbai, Maharashtra

Partner

Mr. Sunil Bakliwal

Address

office no 101, 1st floor, New Krishna Niwas, Roshan Nagar Road, Borivli-(West), Mumbai, Maharashtra, 400092, India

insulating brick in Mumbai

Report incorrect details