Magnesium Production Line Pidgeon Process Capacity: 5000-20000 (T / A) Cubic Meter (M3)

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Magnesium Production Line |

| General Use | Magnesium Production |

| Capacity | 5000-20000 (t / a) Cubic Meter (m3) |

| Computerized | Yes |

| Feature | Simple Control, High Performance, Low Noise, High Efficiency, Lower Energy Consumption, ECO Friendly, Stable Operation |

| FOB Port | Qingdao |

| Payment Terms | Telegraphic Transfer (T/T) |

| Main Export Market(s) | Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America |

Product Overview

Key Features

-----------------------

We have done many successful projects in both China and overseas countries. POSCO is world class iron and steel supplier in Korea. Their magnesium alloy production lines are supplied by us. We can provide plant design, equipment/spare parts supply, consultation and technical service for dolomite & magnesite calcination.

- More than 50 years experience in magnesium industry.

- Design capacity of single production line: 5,000-25,000 tons per year.

- Professional Process Design Engineers, Equipment Engineers, Electrical Engineers.

- Leading supplier of magnesium production line, and over 90% market share.

----------------------

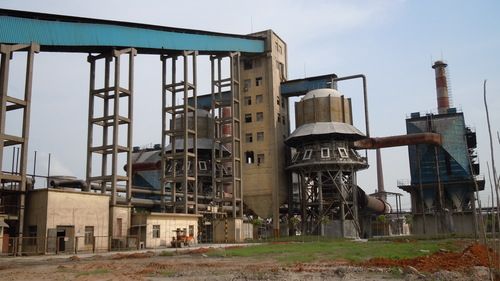

Transported by inclined Belt Conveyor, the fine crushed dolomites will be sent to the Hopper on the top of Preheater and then discharged into Preheater by feeding chute. The high temperature gas from rotary kiln can preheat the dolomites to 800a . Some of the dolomites can dissociate after preheating. After this process, the dolomites are push out by hydraulic push-rod and get into the Rotary Kiln for calcination with 1100-1250a through transfer slide. After calcination, all the materials are discharged into Cooler for cooling to less than 100a and then discharge to next process for grinding.

Company Details

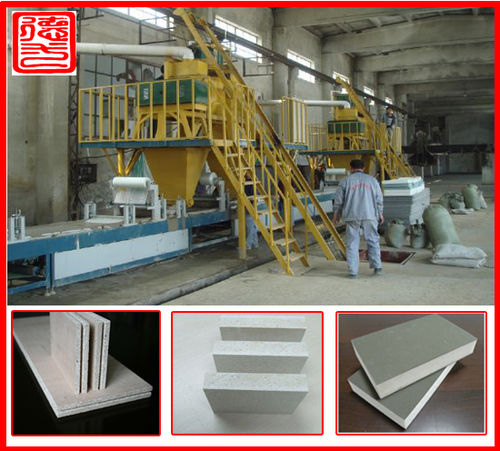

Henan Zhengzhou Mining Machinery Co., Ltd. Henan zhengzhou mining machinery co.,ltd is leading mining equipments manufacturing in the world, who has provided innovative technology and products for mine and energy of over 100 countries and district. It is built in 1956 and locates its factory in xinngyang, henan, china. It is appointed as the fixed equipment-providing factory by chinese ministry of machine building and henan mechanical electronic bureau. The development during the last half century has witnessed its capital assets being over rmb100000000 and becoming a comprehensive modern enterprise with the service of scientific research, design, manufacture, sales, installation, commissioning and worker training. The production lines provided by us mainly include: magnesium production line, cement production line, lime production line, ore dressing line, and oil proppant production line, main products include: rotary kiln, ball mill, granulator, bucket elevator, vertical preheater, vertical cooler, crusher.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

200

Establishment

1956

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Zhengzhou, Henan

Mr. Zhang

Address

Qiaoloucaizhai Industrial Park, XingYang, Zhengzhou, Henan, 450000, China

Industrial Machinery & Parts in Zhengzhou

Report incorrect details