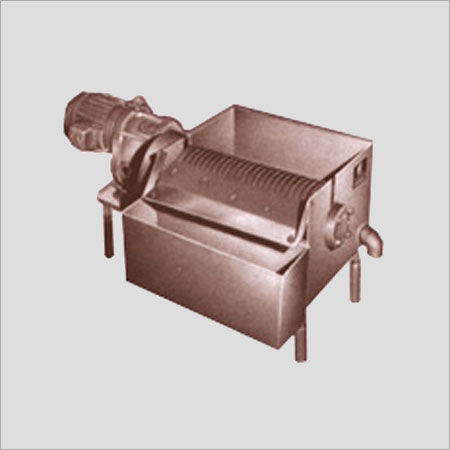

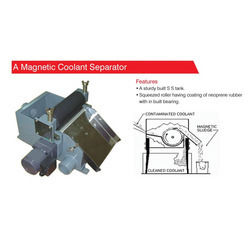

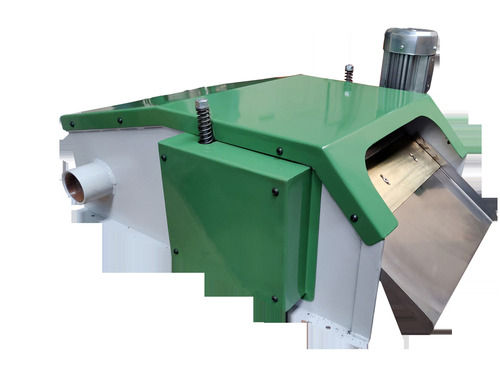

Magnetic Coolant Separator - Stainless Steel 304 | Fully Automatic, Bulk Removal Of Ferrous Material, Diffuser Box, Rare Earth Magnetic Roller, Rubber Squeezer, Brass Scraper, Collection Tray

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Overview

Key Features

Bulk Removal of Ferrous Material

Fully automatic operation

Diffuser box to reduce velocity of the coolant

Oriented O Ring ferrite magnetic roller or Rare Earth magnetic roller in SS 304 enclosure

Standard or Fin type roller

Designed as per requirement in MS or SS body and available for standalone machine as well as for centralized filtration system

Brass scrapper with collection tray

Rubber squeezer to remove traces of coolant from deposited metallic burr

Operation:

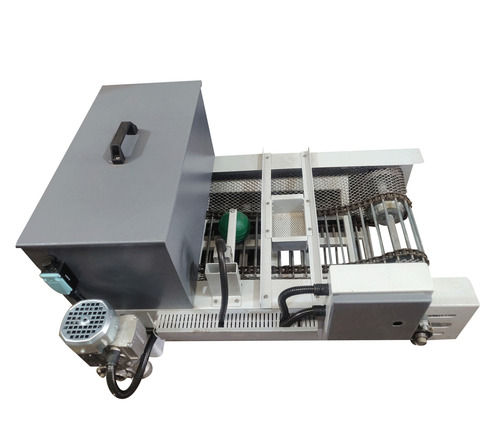

The proposed system is fitted on top of a tank or a Paper Band Filter and incorporates automatic operation for separation of metallic burr from coolant.

The return Coolant after machining operation is rushed to Magnetic Separator by gravity with velocity. The diffuser box helps to reduce the velocity and spreads the Coolant around the magnetic roller.

Magnetic roller is rotated with the help of electric motor mated with speed reduction gear box.

Rotating magnetic roller attracts the metallic burr from the Coolant. As the Coolant velocity is reduced, maximum amount of metallic burr gets deposited on the magnetic roller.

Rubber squeezer rotates against magnetic roller to remove traces of Coolant from deposited metallic burr.

Metallic burr is separated from the rotating magnetic roller using adjustable brass scraper. Burr is collected in the waste collection box.

Coolant is returned to Clean Tank after removing bur.

Waste collection box has to be emptied manually as and when needed.

Key Features:

Bulk Removal of Ferrous Material

Fully automatic operation

Diffuser box to reduce velocity of the coolant

Oriented O Ring ferrite magnetic roller or Rare Earth magnetic roller in SS 304 enclosure

Standard or Fin type roller

Designed as per requirement in MS or SS body and available for standalone machine as well as for centralized filtration system

Brass scrapper with collection tray

Rubber squeezer to remove traces of coolant from deposited metallic burr

Operation:-

The proposed system is fitted on top of a tank or a Paper Band Filter and incorporates automatic operation for separation of metallic burr from coolant.

The return Coolant after machining operation is rushed to Magnetic Separator by gravity with velocity. The diffuser box helps to reduce the velocity and spreads the Coolant around the magnetic roller.

Magnetic roller is rotated with the help of electric motor mated with speed reduction gear box.

Rotating magnetic roller attracts the metallic burr from the Coolant. As the Coolant velocity is reduced, maximum amount of metallic burr gets deposited on the magnetic roller.

Rubber squeezer rotates against magnetic roller to remove traces of Coolant from deposited metallic burr.

Metallic burr is separated from the rotating magnetic roller using adjustable brass scraper. Burr is collected in the waste collection box.

Coolant is returned to Clean Tank after removing bur.

Waste collection box has to be emptied manually as and when needed.

Company Details

Business Type

Manufacturer, Supplier, Retailer

Employee Count

20

Establishment

2015

Working Days

Friday To Wednesday

GST NO

27AAKFC4837H1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAKFC4837H1Z9

Pune, Maharashtra

Mr Santosh Desai

Address

Plot No - 34/H and 34/I, Gat No 729, Jayawant Industrial Estate, Satara Road, At post Velu, Pune, Maharashtra, 412205, India

magnetic coolant separator in Pune

Report incorrect details