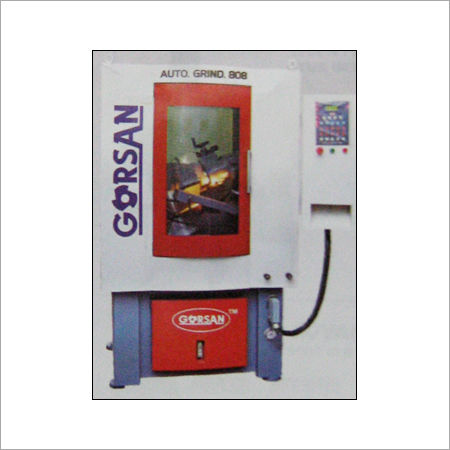

Being a client-centric firm, we are engaged in manufacturing, exporting and supplying an optimum quality Manual Grinding Machine. Our offered range of machine is manufactured by utilizing excellent quality components and with the aid of our advanced equipments under the surveillance of our deft professionals. Available in different specifications, our esteemed clients can purchase this machine as per their preferences. This Manual Grinding Machine is extensively used in engineering industry for providing precise finishing and accurate cutting on diverse objects.Features: Sturdiness Low power consumption High performance Application specific structure BHURJI DEVELOPMENT BHURJI microfeed Surface Grinder Machines are being manufactured in INDIA only by INJECTMAN PLASTICS, FARIDABAD for over 30 years now (Established in 197{3), They have introduced new line of surface Grinder Machine 'SUPERCUT SERIES', These Grinders are designed on both logical thinking and practical experience to meet the utmost requirement of customers for production as well as tool room, X AXIS LONGITUDIONAL TRAVEL The grinding table travel in V & flat ways of cross slide in oil dip and is coated wit resistance, low friction & lasting accuracy. The slide are perfectionally hand scraped and I for easy & free movement. Y AXIS VERTICAL HEAD MOT/ON This box type vertical column is heavy duty type and ribbed which in turn houses the spindle head. Ultra precision precision hardened nitralloy spindle grease packed runs in anti-friction bearings and directly drivet by flange mounted motor (to eliminate any vibration) through flexible couplings, its production and testing passes through rigorous inspection at manufacturing stages to ensure smooth and trouble free running and sensitively essential for extra ordinary finish. SCREWS AND GEARS All the screws are of made up '41 B' material and nitrided for long lasting accuracy and life. Also all the bushes are of PBI material. LUBRICATION SYSTEMS Centralised lubrication is provide through manual oil pump, All the guide surface and.Screws are lubricated through the lubrication pump SPECIFICATIO/JPF MODELS SCS-9140T SCS-1022 OT Working Surface of Grinding Area Max. Magnetic Table Travel Lx W Max. Grd. Heigh Under Wheel Vertical Feed Graduation Cross Feed Graduation Elevator Movement with MICROFEED Spindle Speed Grinding Wheel Size (Dia x Bore x Width) Electric Motor Recommended Magnetic Chuck Suitpble(Optionql) Dimond Dresser with Holder Wooden Case Dimension 200 x 300 mm 250 x 360 mm 240 mm 0.01 mm 0,05 mm 0.002 mm 2800 RPM 178x31.75x 12,7 mm 0.75 HP-3 PHASE (2800 RPM) 200 x 300 mm 0.5CR 1070 x 1200 x 1700 250 x 500 mm 250 x 550 mm 240 mm 0.01 mm 0,05 mm 0.002 mm 2800 RPM 178x31.75x 12.7 mm 1 HP-3 PHASE (2800 RPM) 250 x 500 mm 0.5CR 2000 x 1250 x 1775