Mbs Impact Modifier Application: Textile Industry

Price Trend: 450.00 - 1150.00 USD / Ton

Get Latest Price

Minimum Order Quantity :

5 Ton

In Stock

Product Specifications

| Shelf Life | 2 Years |

| Grade | Industrial Grade |

| Physical Form | Powder |

| Application | Industrial, Textile Industry |

| Shape | Granules |

| CAS No | 63231-66-3 |

| Type | Chemical Additive |

| Color | White |

| Usage | Construction Chemical Additive |

| Purity(%) | 99.9% |

| Storage | Room Temperature |

| Appearance | Clear Powder |

| FOB Port | Shandong, China |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Cash Advance (CA) |

| Supply Ability | 10000 Per Month |

| Delivery Time | 7-12 Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | 25kg/bag |

| Main Export Market(s) | Western Europe, North America, Eastern Europe, Middle East, South America, Asia, Central America, Australia, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

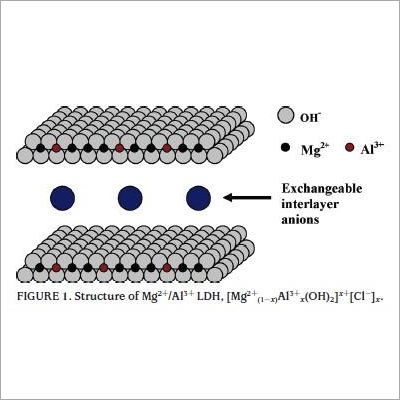

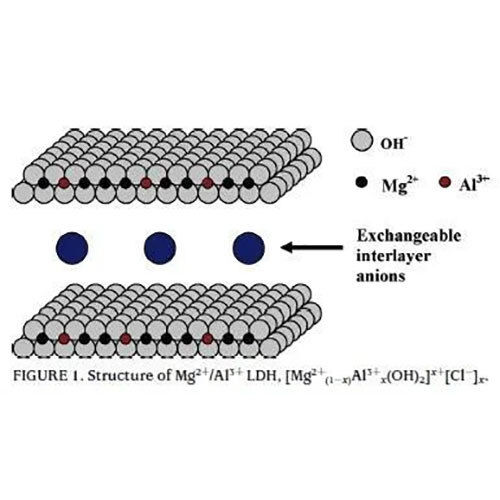

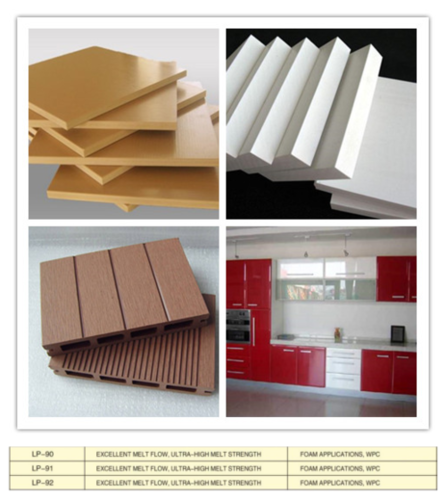

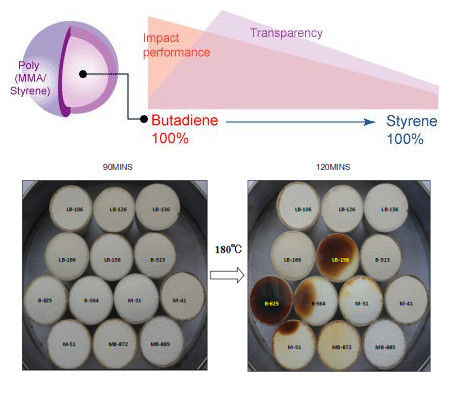

MBS resin is a kind of core-shell copolymer which is grafted by MMA and dried by salting out. The modified PVC can improve its impact strength and comprehensive properties. Because of its similar refractive index with PVC, the modified PVC has better transparency, so it is widely used in transparent products. It is not suitable for outdoor products because it contains butadiene, which is easy to decompose and age when exposed to light.MBS can not only give good toughening effect and excellent transmittance of hard PVC, but also improve its processability, because MBS intertwined PVC in the plasticizing process and rubbed each other, which not only promoted the disintegration of PVC particles, but also bonded with PVC particles, which promoted the gelation of PVC. Therefore, the melting time is shortened, the residence time of the material in the extruder is reduced, the decomposition of PVC is prevented, and the processability of PVC is improved.

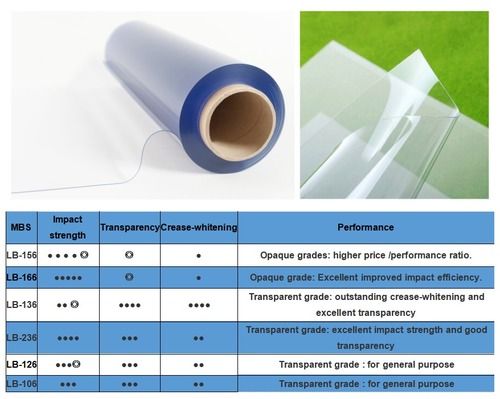

Our impact modifiers equivalent to the Dow Paraloid BTA series,Kane Ace B series,LG MB series,Mitsubishi Metablen C series,Arkema CLEARSTRENGTH C series.

LB-106 equivalent to Dow BTA-707,Kaneka B-622,Arkema C-140,LG MB-870.

LB-126 equivalent to Dow BTA-717,Kaneka B-22,Arkema C-215A,LG MB880.

LB-136 equivalent to Dow BTA-730,Kaneka B-625/B-628,LG MB-885.

LB-156 equivalent to Kaneka B-56,LG MB836.

LB-166 equivalent to Dow BTA-751,Kaneka B-564,Arkema C-323,LG MB838.

For TDS and MSDS, you can contact our Sales and Marketing Department or you can reach us through thecontact page.

Company Details

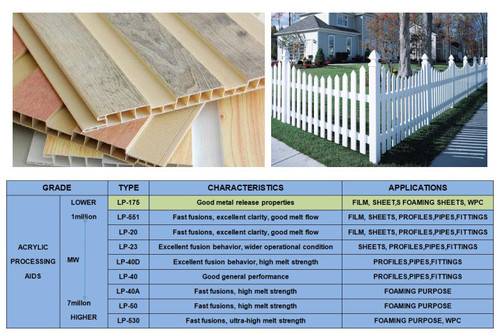

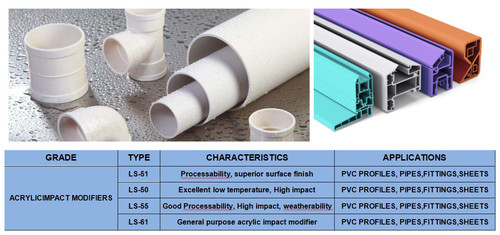

Shandong Repolyfine Chemical Co.,Ltd established in 2016 ,it is a high-tech chemical center that focus on R&D, manufacturing and marketing of additives for PVC industry. It is a jointed party to develop and promote 3 main brands Ruifengpoly,Youdaowax and Repolyfine who specialized in manufacturer different PVC additives and has focused in China PVC market long period. We has advanced production and quality control equipment, with professional R&D personnels,and passed through the ISO9001:2008 international quality system certification. The leading products we developed include:Acrylic Processing Aid,Acrylic Impact Modifier,MBS Impact Modifier,CPE,PVC Internal/External Lubricants,Blowing Agent,Oxidized Polyethlene Wax,Pe Wax,ASA Resin and PVC Stabilizer. All 3 brands has already taken top market share in China domestic.With the jointed work established,we now promote the oversea market and has exported to more than 40 countries like America, India,Korea,and Southeast Asia countries .Repolyfine preliminary build the good reputation and recognized by oversea market.

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier

Employee Count

600

Establishment

1994

Working Days

Monday To Sunday

Payment Mode

Letter of Credit (L/C)

Certification

ISO9001:2008

Related Products

Explore Related Categories

Seller Details

Zibo, Shandong Sheng

Director

Mr Hein Zhou

Members since

11 Years

Address

Yiyuan Economic Development Zone, Zibo, Shandong Sheng, 256100, China

pvc impact modifier in Zibo

Report incorrect details