Molybdenum Disilicide (Mosi2) Heating Element - Customizable Length 150-700mm, U-type, W-type, L-type Shapes | Maximum Operating Temperature 1800â°c, Excellent Anti-oxidation Properties, Versatile For Ceramics, Metallurgy, Glassmaking

Price: 15 USD / Piece

Get Latest Price

Minimum Order Quantity :

100 Piece

In Stock

Product Specifications

| Usage | used in metallurgy, Research and production of steelmaking, glass, ceramics, refractory materials, crystals, electronic components, and semiconductor materials manufacturing and other fields |

| Height | as your request Millimeter (mm) |

| Color | Natural |

| Length | as your request Millimeter (mm) |

| Size | as your request |

| Product Type | jx002 |

| Insulation Material | no |

| Shape | U type ; W type ;L type and other special type |

| Power | 220 Volt (v) |

| Warranty | yes |

| FOB Port | dalian |

| Payment Terms | Telegraphic Transfer (T/T), Western Union |

| Supply Ability | 100000 Per Year |

| Delivery Time | 10 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Export polywood case |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

Application:

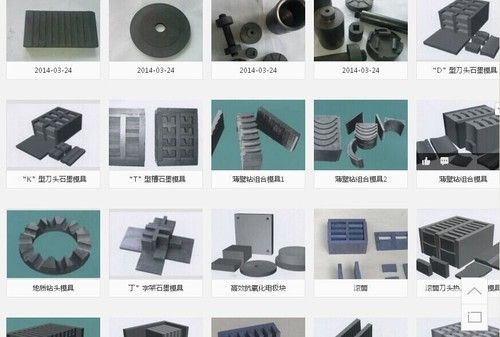

Silicon molybdenum rod electric heating elements are widely used in metallurgy, steelmaking research and production, glassmaking, ceramics, refractory materials, crystal and semiconductor manufacturing, and other fields. They are especially valued in high-performance ceramics, precision optics, and advanced alloy steel production, including sintering and heat treatment processes for ceramics, magnets, glass, metallurgy, and refractories.

Advantages:

Mosi2 heating elements quickly form a thin, adherent anti-oxidizing quartz glass (SiO2) layer under high-temperature oxidizing conditions. If this protective layer is damaged, the element can regenerate a new one, providing excellent anti-oxidation properties and prolonged operational lifespan compared to traditional heating elements. The resistivity of Mosi2 remains stable over time, allowing for easy replacement without affecting existing elements, thereby reducing furnace maintenance costs and downtime, and enhancing operational efficiency.

Specifications:

Molybdenum disilicide MoSi2 rod heating element size:

Diameter: 3/6mm, 6/12mm, 9/18mm, 12/24mm

Length: 150mm to 700mm (customizable)

Operating temperature: 500A C to 1800A C

Rod shapes: Straight, U-shaped, W-shaped, L-shaped, and other special types

Function: Furnaces for ceramics, magnetic materials, glass, metallurgy, and fireproofing materials.

Installation of Mosi2 Heating Element:

Vertically Hanging:

MoSi2 elements are very brittle at normal temperatures but become plastic at high temperatures. To prevent mechanical stress directly on the heat-generating end, U-shaped elements should be vertically hung from the furnace top using support clamping chucks.

Support Clamp:

Support clamps are used for 9/18 and 6/12 elements respectively to bear the weight and position the element vertically. Careful installation is necessary to avoid local overheating, ensuring the tapered end of the lower element is inside the furnace chamber.

Please provide the following information when placing an order for MoSi2 muffle furnace heating elements:

(1) Le: Length of Hot Zone

(2) Lu: Length of Cold Zone

(3) D1: Diameter of Hot Zone

(4) D2: Diameter of Cold Zone

(5) A: Shank Spacing

Company Details

we provide sic heater mosi2 heater silicon carbide tube graphite sagger graphite heater exhibition carpet rib carpet bathroom carpet pvc floor

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

100

Establishment

1997

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Liaoyang, Liaoning

Ceo

Mr Bai Ye David

Members since

2 Years

Address

No.231, Zhonghua Street, Liaoyang, Liaoning, 111000, China

molybdenum heating element in Liaoyang

Report incorrect details