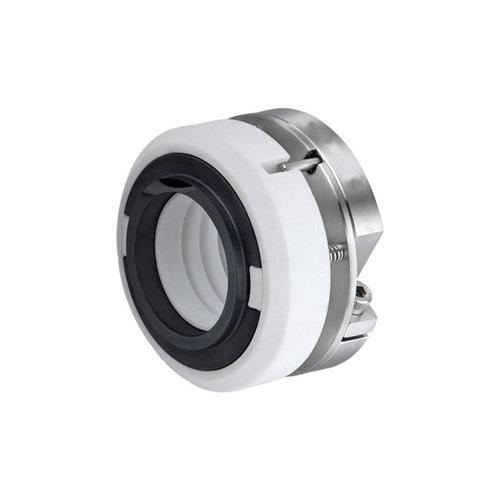

Multi Spring Mechanical Seal

Price: 2500 INR / Piece

Get Latest Price

Minimum Order Quantity :

10 Piece

In Stock

Product Specifications

| Application | Used in chemical, petrochemical, and general industrial applications |

| Usage | Offers balanced sealing performance for high-pressure and high-speed rotating equipment with uniform spring load distribution |

| Color | Metallic Silver |

| Product Type | Multi Spring Mechanical Seal |

| Size | 25mm |

| Style | Other, Mechanical Seal |

| Material | Metal |

| Payment Terms | Cash Advance (CA), Cash in Advance (CID) |

| Supply Ability | 1000 Per Week |

| Delivery Time | 1 Week |

| Main Domestic Market | All India |

Product Overview

Key Features

Prevent a pressure drop across a seal face.

Eliminate atmospheric conditions outboard of a mechanical seal.

To break down the pressure in a high pressure application, by inserting an intermediate pressure between the seals. Two lower pressure seals can then be used to seal a high pressure fluid that would normally require a very expensive high pressure mechanical seal.

To provide a lubricant if one is needed to prevent a slip sticka . This is almost always the case when you are sealing a gas.

Dual seals can be of either the rotating or stationary version and can be installed in four different configurations.

Back to back or facing in opposite directions

Tandem or facing in the same direction

Face to face or facing towards each other

Concentric or one inside the other.

The fluid that circulates between the seals is called barrier fluid if it is higher than stuffing box pressure. It is called buffer fluid if it is lower than stuffing box pressure. It can be circulated between the two seals by:

Natural convection using a convection tank. Insulated piping coming from the top of the gland to the convection tank, and finned piping coming out of the tank will aid convection if heat removal is a problem.

A pumping ring can be installed between the seals for those instances where natural convection is not sufficient to remove the heat being generated between the faces. This is very necessary when oil is used as the barrier fluid. Oil has a low specific heat and poor conductivity, making it a poor choice as a barrier fluid. Most of the newer cartridge dual seals come equipped with a built in pumping ring.

Introducing the fluid between the seals, from an external source. Be sure to bring the fluid in at the bottom of the gland and out the top to prevent an air pocket from forming in the gland.

The following illustrations describe the rotating version (the spring or springs rotate with the shaft) of these dual seal configurations. You should be aware that a stationary version is also available from any of the major seal companies. You should also consider:

Use only the hydraulically balanced version of these seals to prevent the generation of excessive heat between the seal faces.

Two way balance is always desirable in any dual seal application to allow you the option of using either a high or low pressure barrier fluid and to prevent the seal faces from opening if either the system or the barrier fluid pressure fluctuates.

Be sure to select seal faces with good thermal conductivity.

Try to locate any elastomers away from the seal faces if possible. Elastomers are very sensitive to heat.

Company Details

Focusing on a customer-centric approach, SAM SEALS INDIA has a pan-India presence and caters to a huge consumer base throughout the country. Buy Mechanical Seals in bulk from SAM SEALS INDIA at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

2011

Working Days

Monday To Sunday

GST NO

27AMQPK8351E1ZQ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AMQPK8351E1ZQ

Mumbai, Maharashtra

Managing Director

Mr. Sameer

Members since

3 Years

Address

Joshi & Qureshi Compound, Behind Himalaya Hotel, S V Road, Jogeshwari West, Mumbai, Maharashtra, 400102, India

multi spring mechanical seal in Mumbai

Report incorrect details