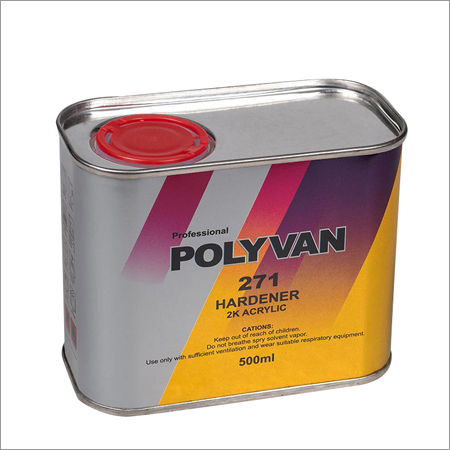

Backed by our team of professionals, we have been a prestigious manufacturer of Nitro Cellulose Primer to our highly respected clients. It is developed for use as primer at various places depending upon our customers requirements. It is known for its high performance, safe usage, durability and a long life as tested by our experts on varied parameters. Nitro Cellulose Primer has gained us high rising demands from our customers for the same. It is available at highly reasonable prices in the market.Features : High resistance against gasoline and mineral oils. Dries fast High glossiness Stability against UV and weather conditions.. Other Details : Flas point: 18oc viscosity: 190 - 200 in DIN4 in 25oc Surface drying time: 5 min Deep drying time: 15 minNitrocellulose AsterDescription: ARKO Nitrocellulose Astar is a nitrocellulose surfacer applied directly before the topcoat layer to obtain a smooth surface . it is manufactured from special alkyd resins and nitrocellulose. it is characterized anti-corrosive and adhesion properties on metal surfaces ,easy sanding , fast drying and perfect filling.Compared to standard paints and varnishes and related standard test methods.Products:POLYVAN Cellulosic PrimerARKO Cellulosic PrimerPackaging:0.5 kg1 kgTypical Substrates:Suitable for bare steel surfaces and wood worksPrimer coat for structural steel works , machinery & pipingAutomotive re-finishes Technical Specifications Appearance Liquid Color Grey, Beige, Black, White Viscosity 115 KU Specific Gravity 1.4 Solubility Insoluble in water Volume Solids 60-70 Pot Life N/A Shore D Hardness N/A Catalist Required N/A Flash Point -5oC Shelf life 24 months VOC (EC) 204.8 g/l Precaution: Read all direction and warnings prior to using Arko products Material Safety Data Sheet(SDS) Application Data Cleaning Surface should be clean and free of dust, grease, and oil. Preparation: Dry sanding : Sand with P280 grit drySanded systems: P80-P180 Mixing ratio (By volume) Arko NC Thinner Number of coats Always apply a thin initial coat to fill minor holes and scratch marks.Extra thin layers can be applied with an interval of 15 mins. Air Dry Surface Dry: 5-10min at 20oCHard Dry: 90min at 20oC Between coats 1 2 minutes Sanding Dry sand with P280 girt Paper. P 600 to P 800 grit wet Application Option 1:1/2 coat Option 2:1 closed light coat Film Thickness: Followed by 1 full coat Followed by 1 full coat (Recommended 40 60 m) 40-50m 50-60m Storage:Store the product dry and at a temperature between 5 and 38C per Arko specification. Store in the original unopened container. Storage temperature may vary per OEM specification requirements. refer to container label for specific storage life information.DisclaimerThe information supplied in this document is for guigance and should not be construed as warranty.All implied warranties are expressly disclaimed. All users of the materials are responsible for assuring that it is suitable for their needs, environment and use. All data subject to change as Arko deems appropriate.