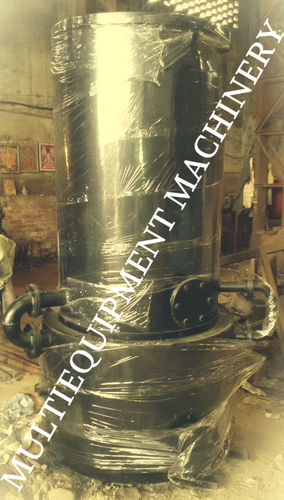

Available with us is a superior quality gamut of Non IBR Boilers. All the boilers offered by us are widely demanded in textile industry for their efficient performance. Non IBR Boilers have pressure jet burner which atomizes the fuel and combustion of the boilers for optimum functionality. Owing to excellent features such as easy installation, instant steaming, fully automatic operation and high quality pressure switch, our entire range is widely demanded in the market. Further, these boilers can run with LPG, CNG, diesel, petrol and LDO.Salient Features Fully automatic instant steaming. Easy operation fail proof system. Record efficiency. Packaged models in unitised design. REVOTECH is the latest design in coil type Non - IBR boilers. incorporating unique revolutionary principle of combustion known as " Reverse Flow " which increases combustion efficiency & allows high rate of heat flux & increases the efficiency of whole system. The boiler is also comprising of an atmospheric economizer to preheat the incoming feed water to boiler. As REVOTECH is a fully automatic boiler there is no need of specially trained boiler attendant during operation. NON - 1BR : The volumetric holding of the steam generating coil is less than 25 litres, by virtue of which the boiler is exempted from Indian Boiler Regulations.Forced circulation, water tube & Reverse flow design enables the boiler to produce steam at full working within 3 to 5 minutes from cold start. REVOTECH is fully safe as it is having all safety precautions. REVOTECH is available in a wide range of steam generating capacities from 50 Kgs/hr to 1000 Kgs/hr F & A 100oC designed for maximum pressure of 15 Kg/cm2 at overall efficiency of 88+ 2% on N . C . V. Technical Specifications Details Unit NT-50 NT-100 NT-200 NT-300 NT-400 NT-600 NT-1000 NT-1500 Operating Parameters Capacity KCals/Hr. 50000 100000 200000 300000 400000 600000 1000000 1500000 Max. Operating Temp. (At the outlet of the unit) oC 300 300 300 300 300 300 300 300 Fuel Oil Consumption At full load LDO FO Kgs/Hr Kgs/Hr. 5.4 10.8 21.5 22.6 32.4 33.9 42.9 45 64.3 67.5 107.2 112.5 160.80 168.75 Efficiency (GCV) % 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 Burner Control ON-OFF Electric Supply AC-3 Phase - 415V +/- 6%; 50 Hz, 4 Wire Connected Elec. Load Thermic Fluid Pump Motor (HP) 3 5 7.5 10 10 20 25 30 Blower Motor (HP) 1 1.5 2 2 3 5 10 12.5 Fuel Oil Preheater (For F.O. Fired Unit Only) KW 3 4.5 4.5 6 9 15 Total Elec. Load For LDO Fired Units For FO Fired Units HP HP + KW 4 6.5 9.5 9.5+3 12 12+4.5 13 13+4.5 25 25+6 35 35+9 42.5 42.5+15 Overall Dimensions Length (Mts) 2 3 4 4 4 4 4 6 Width (Mts) 2 3 4 4 4 5 5 6 Clear Height (Mts) 2.5 2.5 4 5 5 5 6 6 Fuel Gas Outlet (MM) 250 250 250 300 300 400 500 550 Cross Dry Weight (Kgs) 1000 1350 1750 2400 2900 3500 5250 7875